Treatment process for removing soluble organic carbon and total chromium in cold-rolling reverse osmosis concentrated water

A technology of dissolved organic carbon and reverse osmosis concentrated water, which is applied in the field of water treatment, can solve the problems of treatment methods and processes that do not remove dissolved organic matter and total chromium, achieve good social and environmental benefits, and solve the effect of polluting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

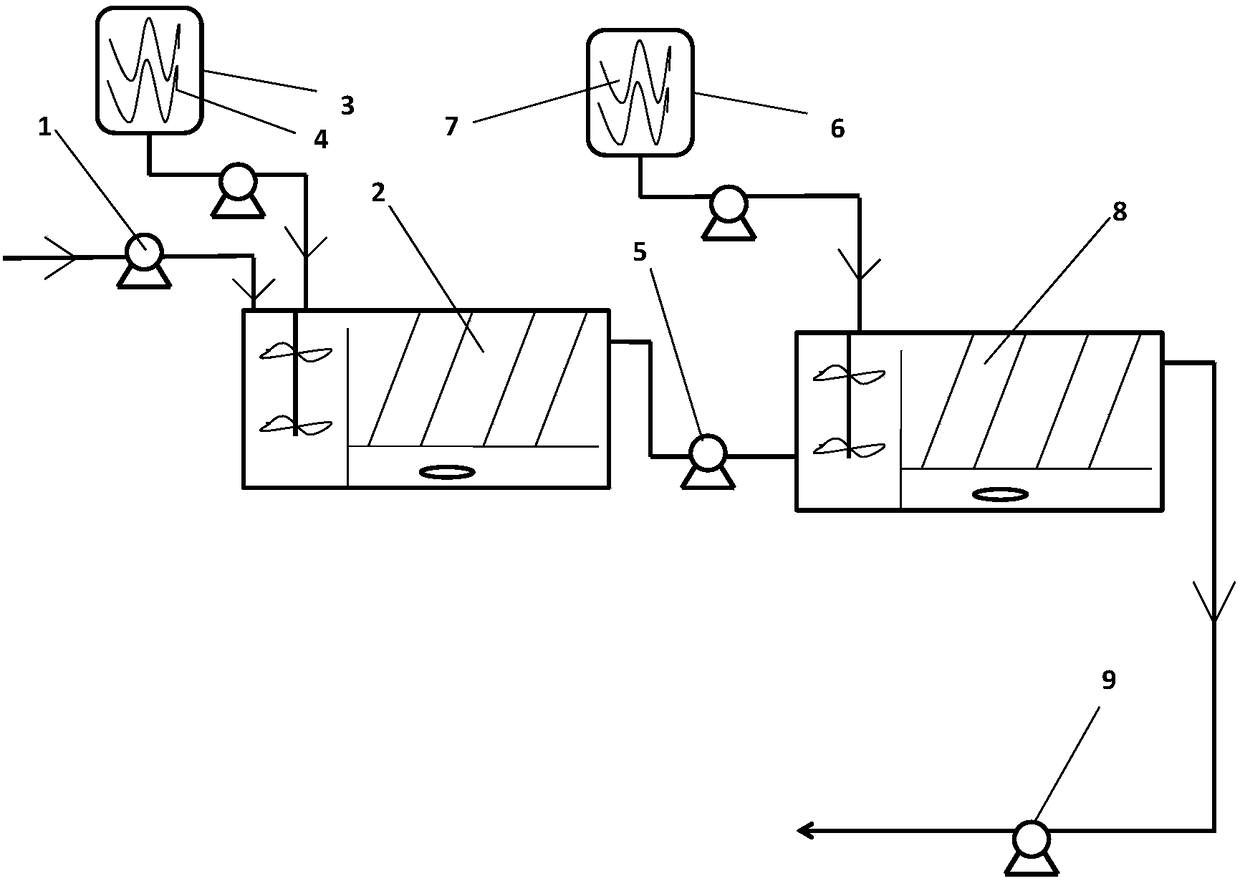

[0037] A process for simultaneously removing dissolved organic carbon and total chromium in cold-rolled reverse osmosis concentrated water, including a water inlet pump, a first-stage inclined plate sedimentation tank, a montmorillonite dosing box and a dosing pump, and a montmorillonite-loaded iron-based reduction agent, lifting pump, modified activated carbon dosing box and dosing pump, modified activated carbon coagulant, secondary inclined plate sedimentation tank, drainage pump (see figure 1 ).

[0038] The water quality characteristics of the cold-rolled reverse osmosis concentrated water: pH is 7.9, electrical conductivity is 14800 μS / cm, dissolved organic carbon (DOC) is 45 mg / L, and total chromium is 5.2 mg / L.

[0039]The cold-rolled reverse osmosis concentrated water enters the first-stage inclined plate sedimentation tank through the water inlet pump. The first-stage inclined plate sedimentation tank is divided into two parts, the front part is the stirring reactio...

Embodiment 2

[0048] A process for simultaneously removing dissolved organic carbon and total chromium in cold-rolled reverse osmosis concentrated water, including a water inlet pump, a first-stage inclined plate sedimentation tank, a montmorillonite dosing box and a dosing pump, and a montmorillonite-loaded iron-based reduction agent, lifting pump, modified activated carbon dosing box and dosing pump, modified activated carbon coagulant, secondary inclined plate sedimentation tank, and drainage pump.

[0049] The water quality characteristics of the cold-rolled reverse osmosis concentrated water: pH is 6.3, electrical conductivity is 17800 μS / cm, dissolved organic carbon (DOC) is 33 mg / L, and total chromium is 3.9 mg / L.

[0050] The cold-rolled reverse osmosis concentrated water enters the first-stage inclined plate sedimentation tank through the water inlet pump. The first-stage inclined plate sedimentation tank is divided into two parts, the front part is the stirring reaction tank, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com