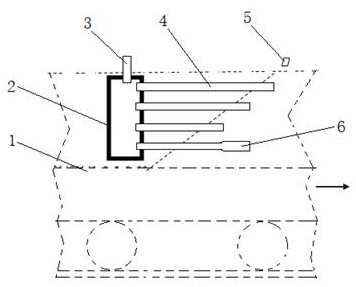

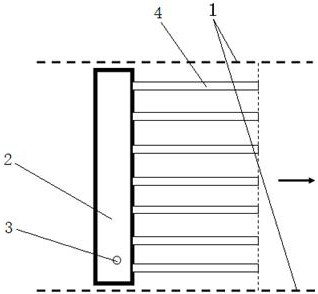

Sintering mixture preheating device and preheating sintering method

A technology of sintering mixture and preheating device is applied in the field of preheating device, sintering mixture preheating device and preheating and sintering to achieve the effects of smooth sintering, improving sintering quality and reducing sintering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The method for preheating the sintered mixture based on the sintered mixture preheating device provided by the present invention comprises the following steps:

[0041] 1) Prepare materials according to the following mass ratios:

[0042] Limonite fines ore 20%

[0043] Magnetite Concentrate 60%

[0044] Limestone Powder 15%

[0046] 2) Stir and mix the materials prepared in step 1), and control the water content to 6% to obtain a sintered mixture;

[0047] 3) Spread the sintered mixture in step 2) on the walking trolley through the distributor, control the thickness of the cloth to 75cm, and make the uppermost horizontal preheating pipe section of the preheater extend into the sintering area 15cm away from the surface of the sintered mixture. In the mixture, the second horizontal preheating pipe section of the preheater extends into the sintering mixture 30 cm away from the sintering mixture surface, and the third horizontal preheating pipe...

Embodiment 2

[0052] The method for preheating the sintered mixture based on the sintered mixture preheating device provided by the present invention comprises the following steps:

[0053] 1) Prepare materials according to the following mass ratios:

[0054] Limonite fines ore 60%

[0055] Magnetite Concentrate 20%

[0056] Limestone powder 9%

[0057] Quicklime powder 7%

[0058] Anthracite powder 4%;

[0059] 2) Stir and mix the materials prepared in step 1), and control the water content to 9% to obtain a sintered mixture;

[0060]3) Spread the sintered mixture in step 2) on the walking trolley through the distribution device, control the thickness of the cloth to 70cm, and make the uppermost horizontal preheating pipe section of the preheater extend into the sintering area 20cm away from the surface of the sintered mixture. In the mixture, make the second row of horizontal preheating pipe section of the preheater extend into the sintering mixture 40cm away from the surface of the ...

Embodiment 3

[0065] The method for preheating the sintered mixture based on the sintered mixture preheating device provided by the present invention comprises the following steps:

[0066] 1) Prepare materials according to the following mass ratios:

[0067] Limonite fines ore 45%

[0068] Magnetite Concentrate 30%

[0069] Limestone powder 5%

[0070] Quicklime powder 7%

[0071] Dolomite powder 7%

[0072] Coke powder 3%

[0073] Anthracite powder 3%;

[0074] 2) Stir and mix the materials prepared in step 1), and control the water content to 7% to obtain a sintered mixture;

[0075] 3) Spread the sintered mixture in step 2) on the walking trolley through the distributor, control the thickness of the cloth to 72cm, and make the uppermost horizontal preheating pipe section of the preheater extend into the sintering area 18cm away from the surface of the sintered mixture. In the mixture, the second horizontal preheating pipe section of the preheater extends into the sintering mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com