Automatic material taking, weighing, blowing-away and feeding device

A feeding device and automatic reclaiming technology, applied in the directions of fiber feeding, textile and papermaking, fiber processing, etc., can solve the problems of relying on manual feeding, unable to meet the needs of independent feeding, and achieve controllable and reliable performance parameters, improve Performance quality, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

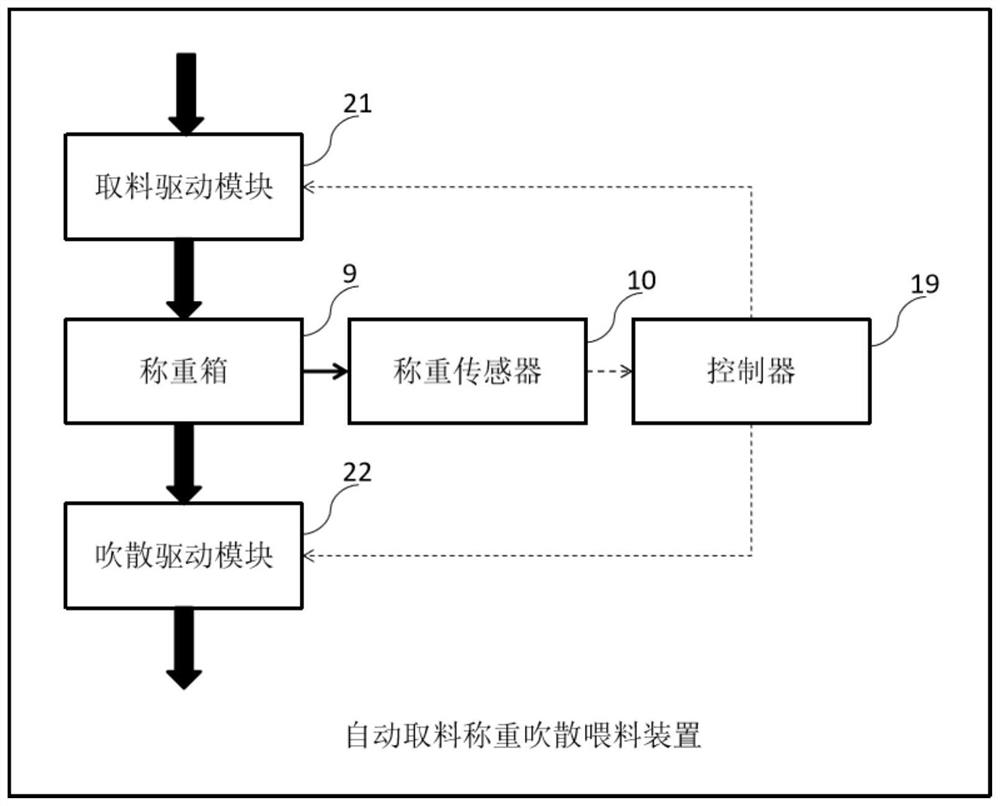

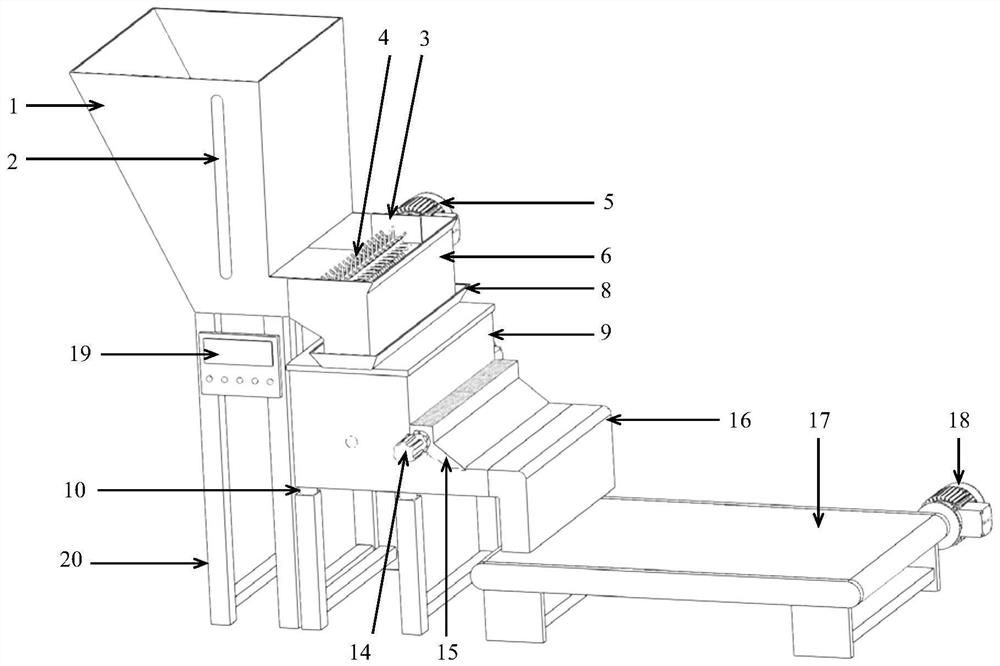

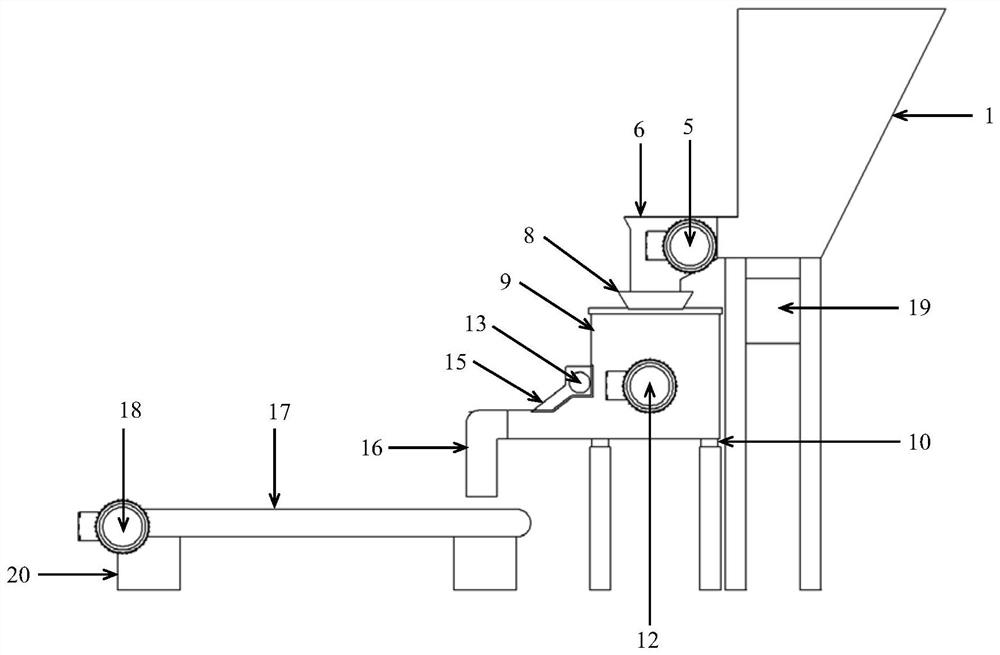

[0043] Please refer to the attached Figure 1-10 , this embodiment discloses an automatic reclaiming, weighing, blowing and feeding device, such as figure 1 As shown, it includes: a reclaiming drive module 21; a weighing box 9; a blowing drive module 22;

[0044] Load cell 10, for obtaining the weight data of weighing box 9;

[0045] The controller 19 is used to receive and process the weight data obtained by the load cell, adjust the material retrieving amount of the retrieving drive module, and adjust the blowing drive module to generate wind force to blow the materials in the weighing box according to a predetermined procedure.

[0046] As a preferred embodiment, the reclaiming drive module 21 includes: a reclaiming motor 5 arranged on the support 20 and a reclaiming shaft 4 directly connected thereto, on which several retrieving shafts 4 are arranged. Material needle, the controller 19 adjusts the reclaiming motor 5, drives the reclaiming rotating shaft 4 and the reclaim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com