Top locking and anchoring mode of pressure type anti-floating pile

An anti-floating pile, pressure type technology, applied in sheet pile walls, protection devices, buildings, etc., can solve the problems of difficult waterproof construction, easy loss of prestress, poor waterproof effect, etc., to reduce the difficulty of waterproof construction, reduce Construction process, reliable effect of waterproof quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

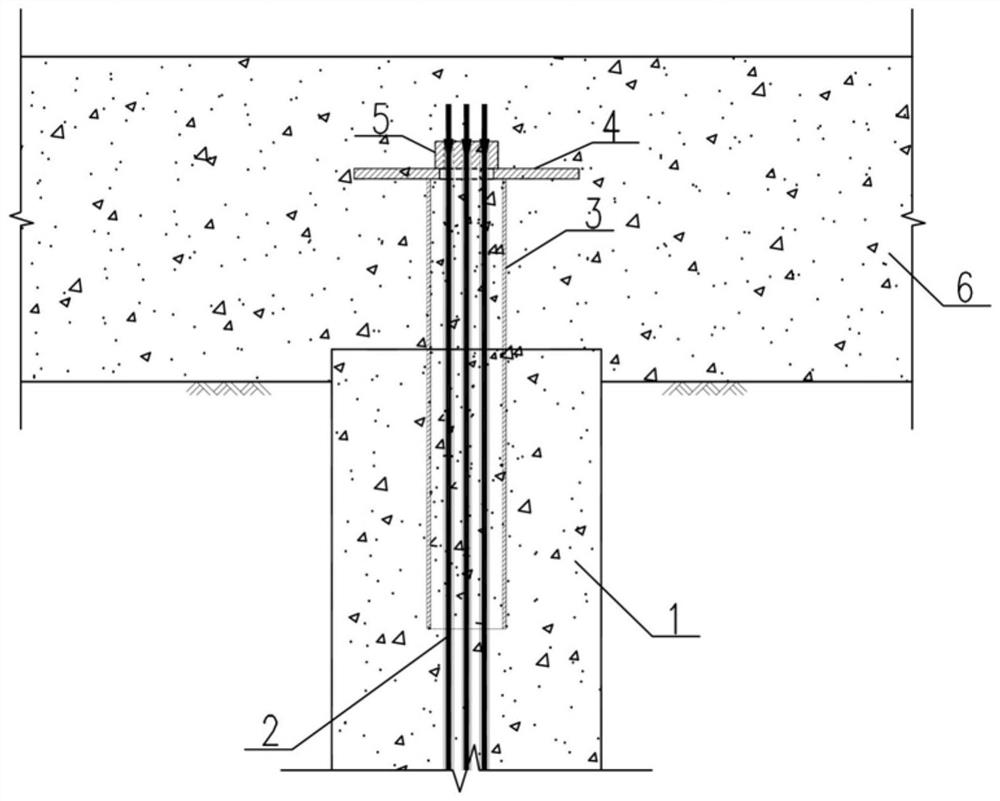

[0019] The following is attached Figure 1-3 The application is described in further detail.

[0020] The embodiment of the present application discloses a top locking and anchoring method of a pressure-type anti-floating pile.

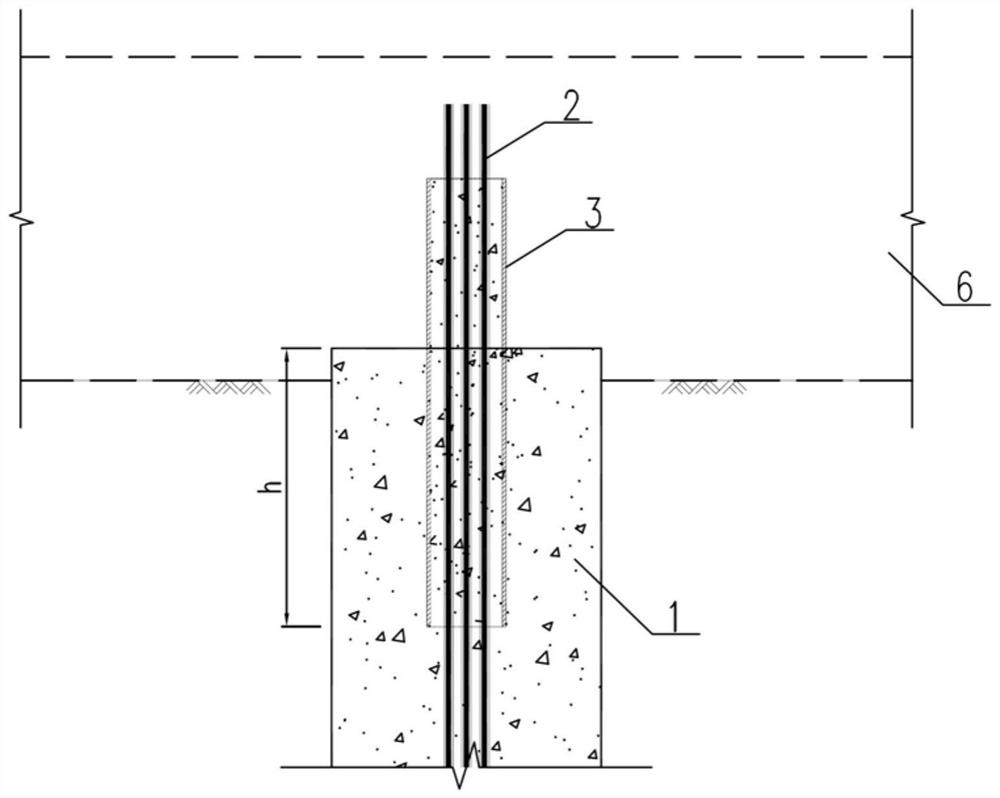

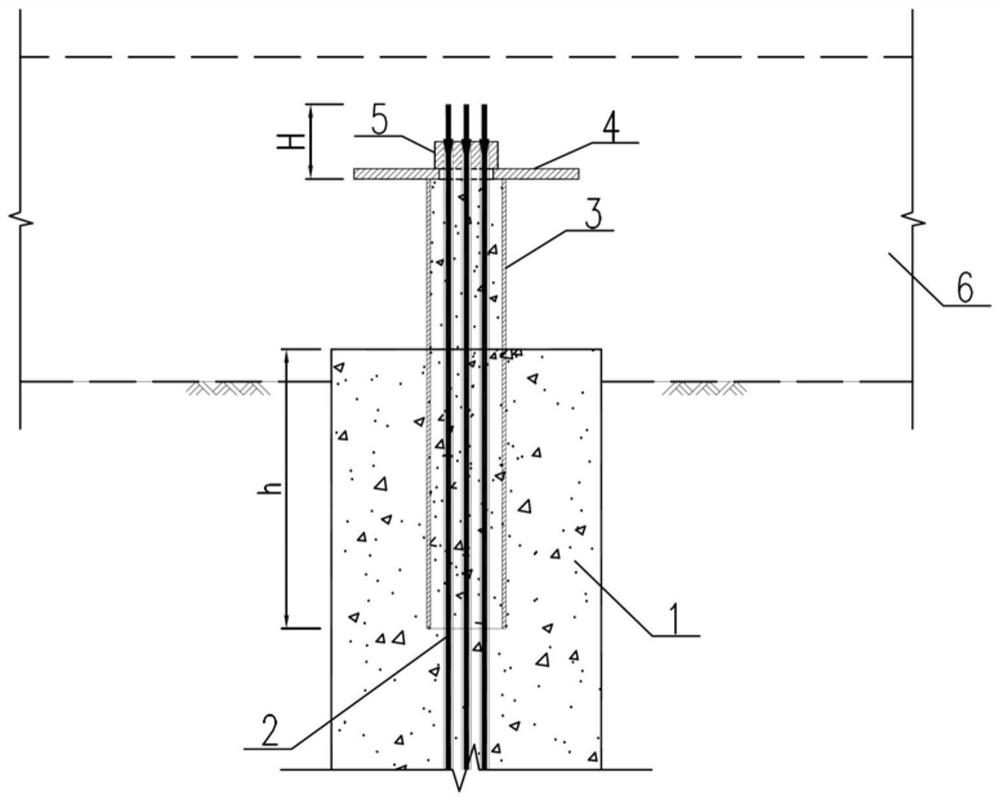

[0021] refer to Figure 1 to Figure 3 , The components included are: pressure-type anti-floating pile body 1, unbonded steel strand 2, short locking steel pipe 3, anchor plate 4, anchorage 5, and foundation 6.

[0022] refer to figure 1 The upper part of the locking short steel pipe 3 is arranged outside the head of the anti-floating pile and inside the foundation 6, and the lower part of the locking short steel pipe 3 is arranged in the pressure type anti-floating pile body 1 before the concrete of the pile body is solidified, and is arranged centrally. The inside of the locked short steel pipe 3 is filled with concrete and vibrated compactly. The diameter and thickness of the locking short steel pipe 3 are determined according to the locking for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com