Air guide ring structure beneficial to reduction of rotation order noise and arrangement method of air guide ring structure

An air guide ring and noise technology, which is applied to the structure of the air guide ring and its setting, can solve the problems of inconsistency, high production cost, poor general effect, etc., and achieves the effect of reducing the noise of the rotation order and having a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

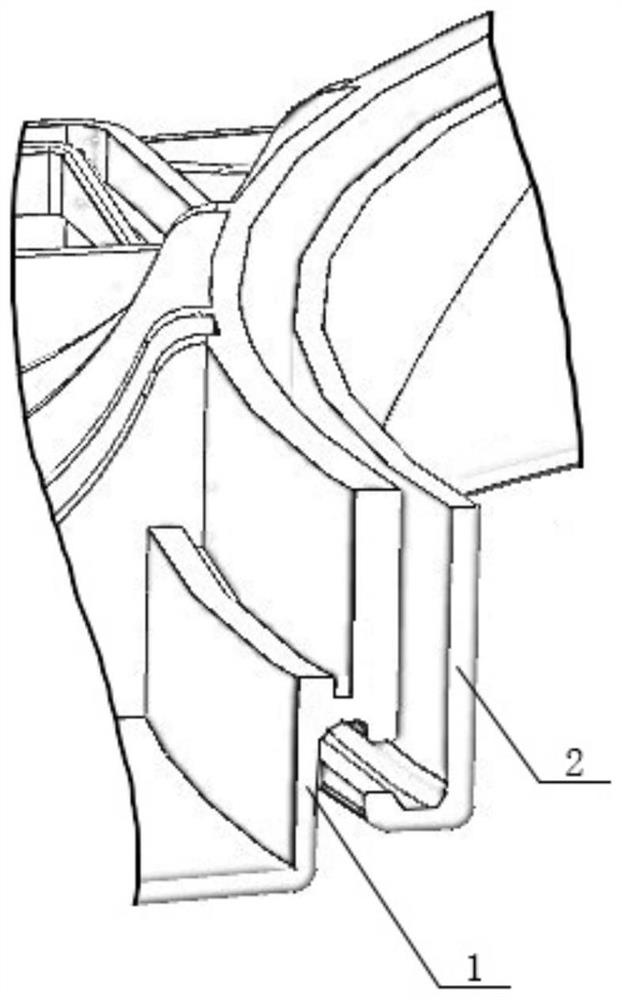

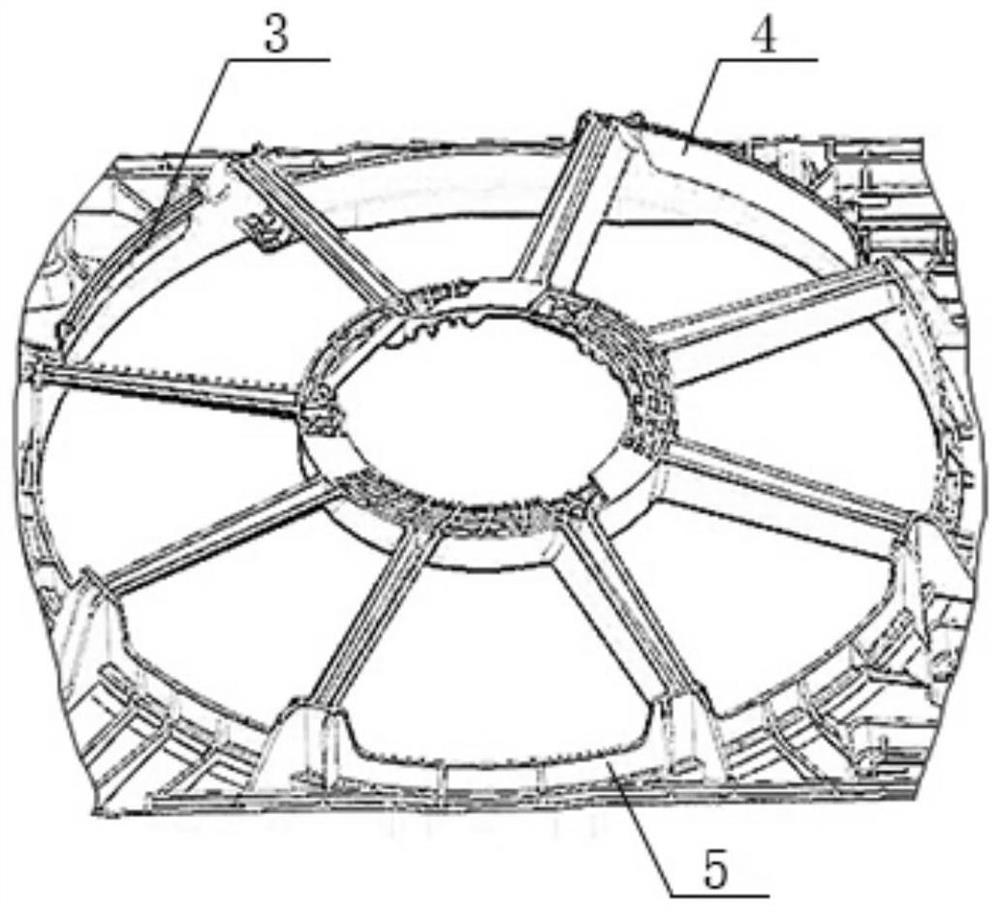

[0027] Embodiment 1. A wind guide ring structure that is beneficial to reduce the noise of rotation order, refer to figure 2 , installed on the air outlet of the wind hood, the air outlet of the wind hood includes a wind guide ring 5, and the wind guide ring 5 is provided with several bosses arranged around the circumference, and the upper part of any boss is connected with the inside of the air outlet of the wind hood by a reinforcing rib The retaining ring in the center is connected, and the air guide ring 5 between any adjacent bosses is provided with an upward opening slot, and at least one guide vane is arranged in the opening slot; one end and the bottom surface of the guide vane and the The opening slot is connected as a whole, and there is a first space between the other end of the guide vane and the opening slot close to it. The arc length of the first space is calculated according to the fluid noise and has passed the physical verification. The present invention ado...

Embodiment 2

[0028] Embodiment 2. On the basis of Embodiment 1, the opening groove is a U-shaped opening groove, and first rounded corners are arranged between the bottom edge of the U-shaped opening groove and the vertical sides on both sides; the bottom of one end of the wind guide vane A second rounded corner is provided, the size of the second rounded corner is the same as that of the first rounded corner, and the vertical edge and the bottom edge adjacent to the second rounded corner on the wind guide vane are connected as a whole with the U-shaped opening groove at the contact point. The space is located between the other end of the wind guide vane and the U-shaped open slot close to it. In the present invention, one end of the air guide vane is integrated with the U-shaped opening groove, which reduces the noise; through the cooperation of the first rounded corner and the second rounded corner, the area of the contact end is increased, the local rigidity is increased, and the air g...

Embodiment 3

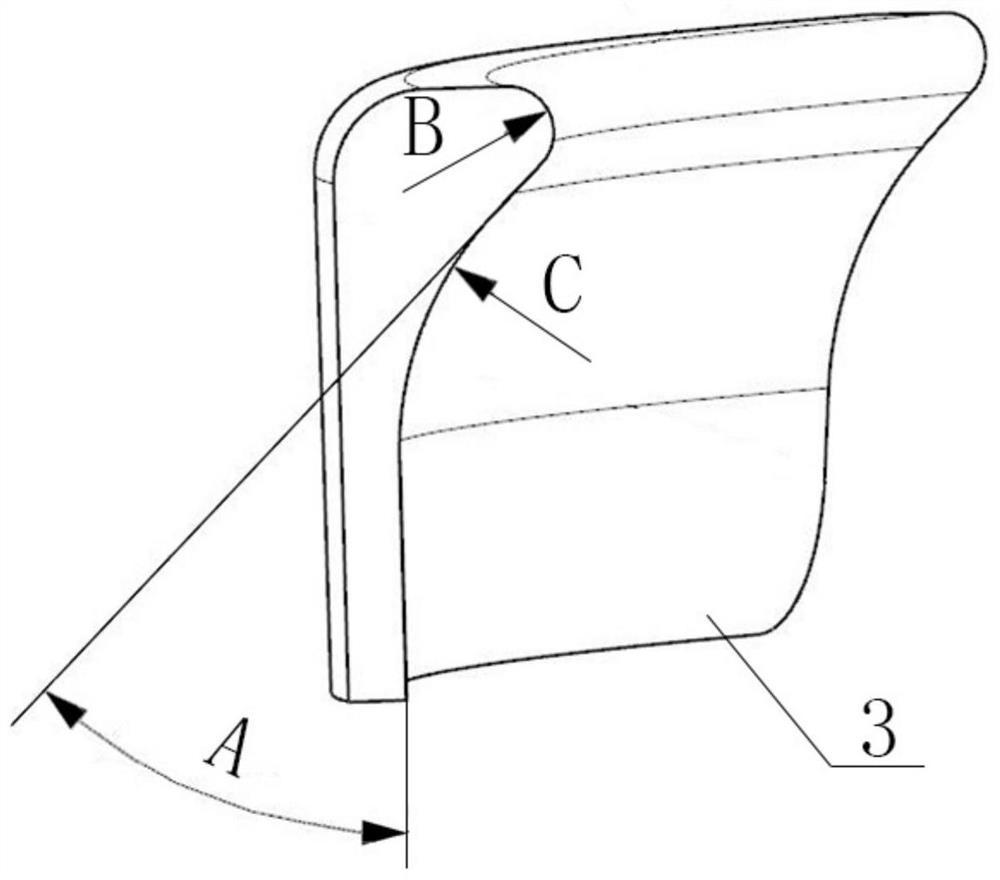

[0029] Embodiment three, on the basis of embodiment two, refer to image 3 , the guide vane includes a first guide vane 3, the first guide vane 3 is a first inferior arc section, and the section of the first inferior arc section along the vertical direction is an inverted J-shaped structure, wherein the inverted J-shaped The straight plate at the lower end of the structure has the same wall thickness as the wind guide ring 5, the bending part of the J-shaped structure faces the side of the center of the wind guide ring 5, and the middle part of the J-shaped structure close to the center of the wind guide ring 5 is a circular arc transition surface , the radius of the arc transition surface is C; the end of the hook part of the J-shaped structure is provided with rounded corners, and the radius of the rounded corners is B. The present invention adopts the first wind guide vane with an inverted J-shaped structure, and sequentially reduces the noise at local points through the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com