Drying device for medicine production and processing

A drying device and medicine technology, applied in the direction of drying gas arrangement, drying solid materials, non-progressive dryers, etc., can solve problems such as uneven drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

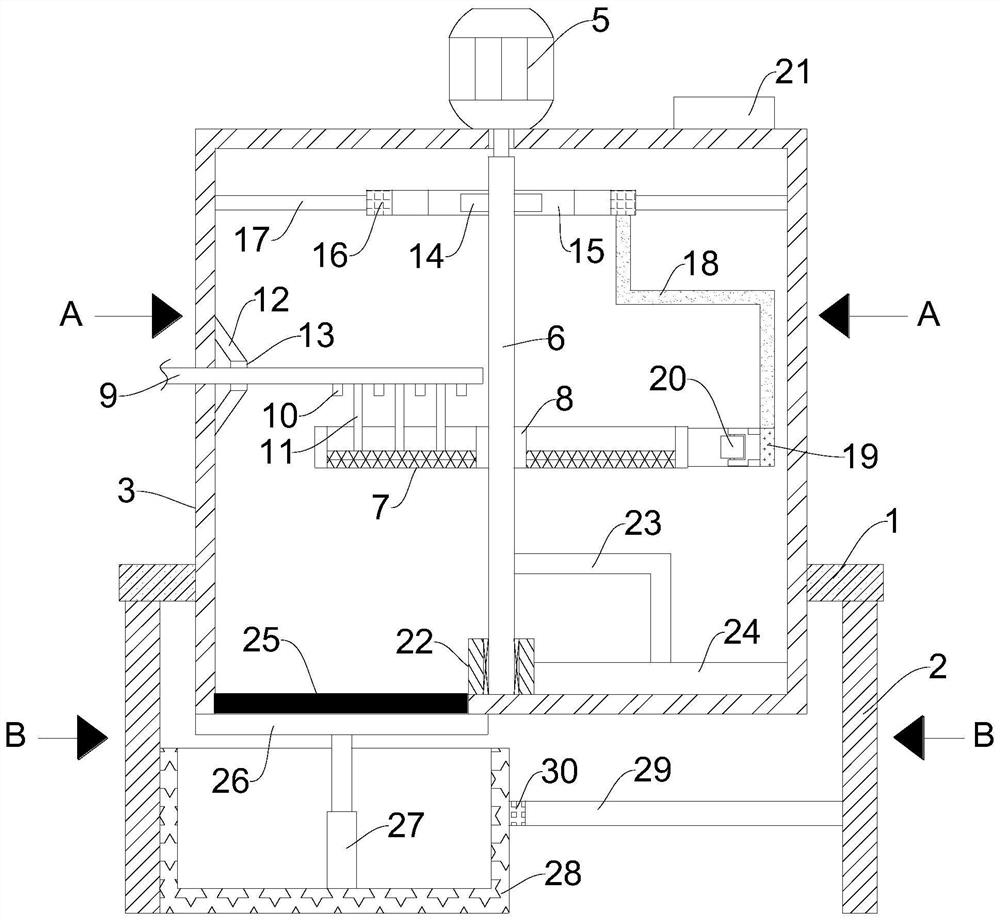

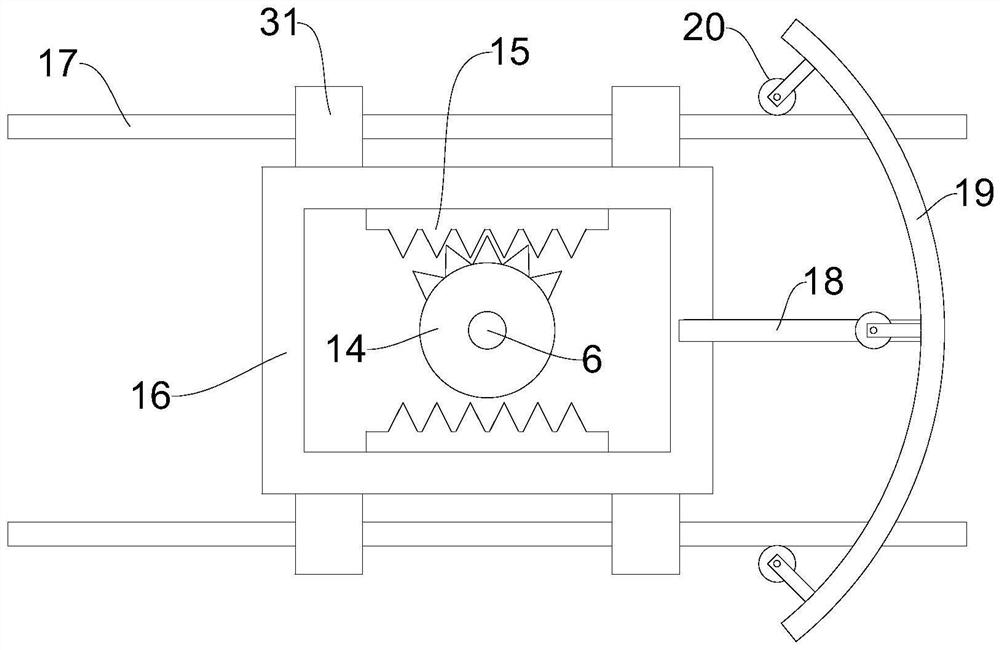

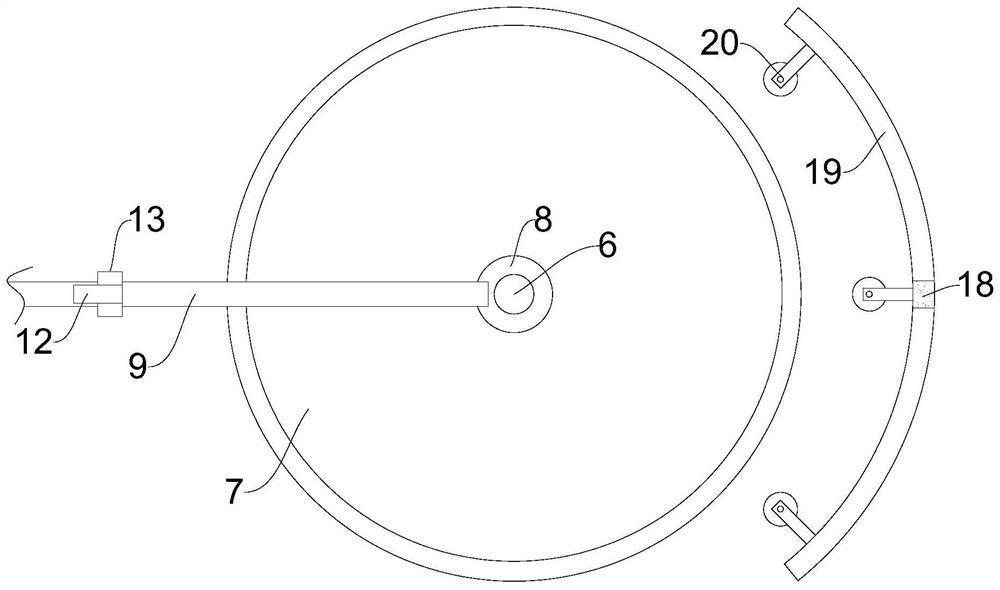

[0023] refer to Figure 1-6 , a drying device for pharmaceutical production and processing, comprising a cylindrical box body 3 and a sealed door 4, the sealed door 4 is mounted on the circumferential side wall of the box body 3 through hinges, and the side wall of the box body 3 below the sealed door 4 An observation window 34 is inlaid and fixed, and a motor 5 is fixedly arranged at the center of the outer top wall of the box body 3. The box body 3 top wall on one side of the motor 5 is connected and fixedly provided with an air outlet pipe 21, and the air outlet pipe 21 is fixedly provided with an air outlet pipe. There is a filter screen, and the top of the output shaft of the motor 5 runs through the top wall of the box body 3 and extends to the inner coaxial center of the box body 3. A rotating shaft 6 is fixed, and the end of the rotating shaft 6 away from the output shaft of the motor 5 is set through a bearing rotation sleeve. The second cylinder 22, one end of the se...

Embodiment 2

[0027] In Example 1, in the process of constantly turning over the tablets to be dried in the tablet storage box 7, the tablets to be dried in the tablet storage box 7 will be broken in a small number of cases, and the broken tablets will fall through the holes on the filter plate. Falling on the inner bottom wall of the box body 3, it is inconvenient for people to clean up the broken tablets falling on the inner bottom wall of the box body 3, refer to figure 1 , 4 , 5 and 6, as another preferred embodiment of the present invention, the difference from Embodiment 1 is that a second fixed rod 23 is vertically fixed on the rotating shaft 6 between the first cylinder 8 and the second cylinder 22 , the end of the second fixed rod 23 away from the rotating shaft 6 is vertically fixed with a scraper 24, and the two ends of the scraper 24 are respectively in contact with the outer peripheral side wall of the second cylinder 22 and the inner side wall of the box body 3, and the scrape...

Embodiment 3

[0029] In embodiment 2, since the discharge port is arranged on the bottom wall of the casing 3, it is very inconvenient for people to extract the sealing plug 25 from the discharge port and install the sealing plug 25 in the discharge port, refer to figure 1 , 4 , 5 and 6, as another preferred embodiment of the present invention, the difference with Embodiment 1 is that a baffle plate 26 is fixedly provided on the lower surface of the sealing plug 25, and the upper surface of the baffle plate 26 around the sealing plug 25 and the casing 3 The outer bottom wall of the shielding plate 26 is vertically fixed with an electric telescopic rod 27 at the center of the lower surface of the shielding plate 26, and the end of the electric telescopic rod 27 away from the shielding plate 26 is vertically fixed with a collection box 28, and the electric telescopic rod 27 is far away from the shielding One end of the plate 26 is vertically fixed on the inner bottom wall of the collection bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com