Electronic detonator initiation device and working method thereof

A detonating device and electronic detonator technology, applied in blasting, offensive equipment, fuze, etc., can solve problems such as inability to separate high and low voltage, potential safety hazards, ignoring system security, etc., to prevent equipment outflow from blasting, reduce potential safety hazards, and eliminate high voltage risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

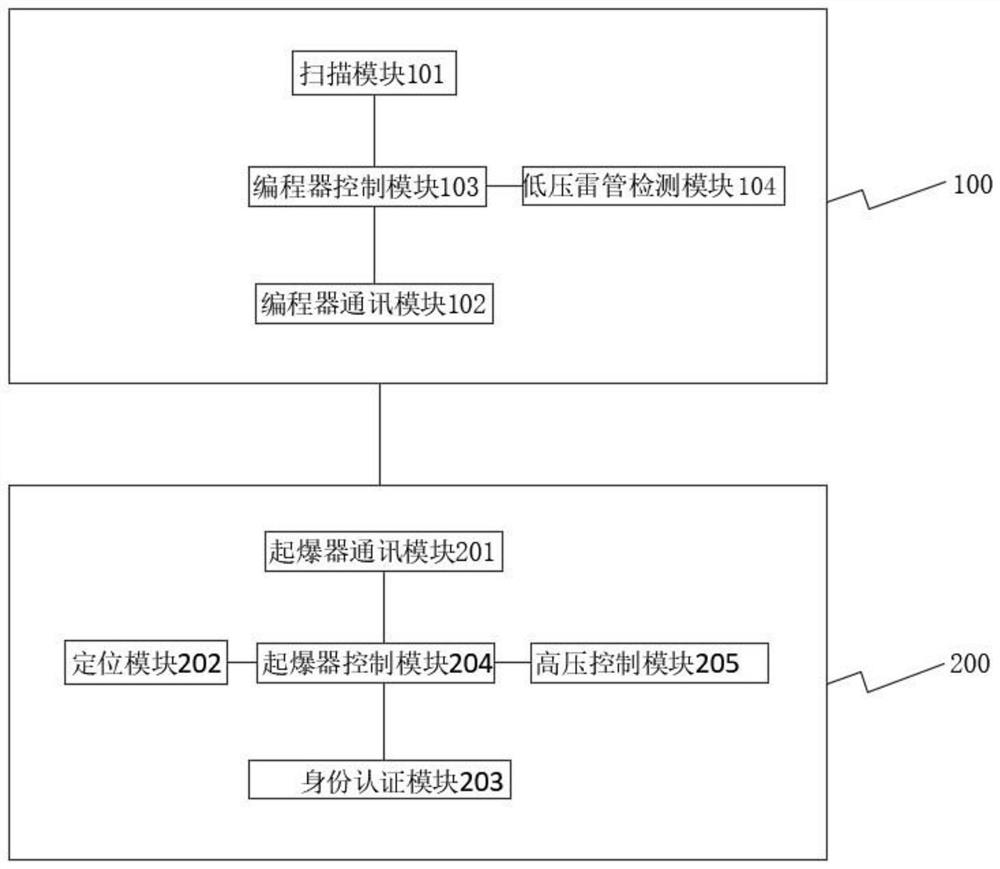

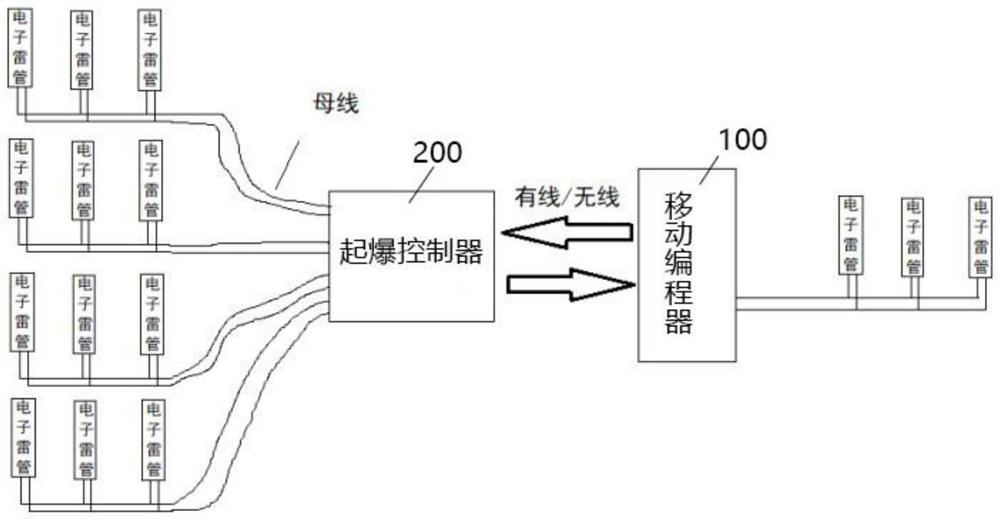

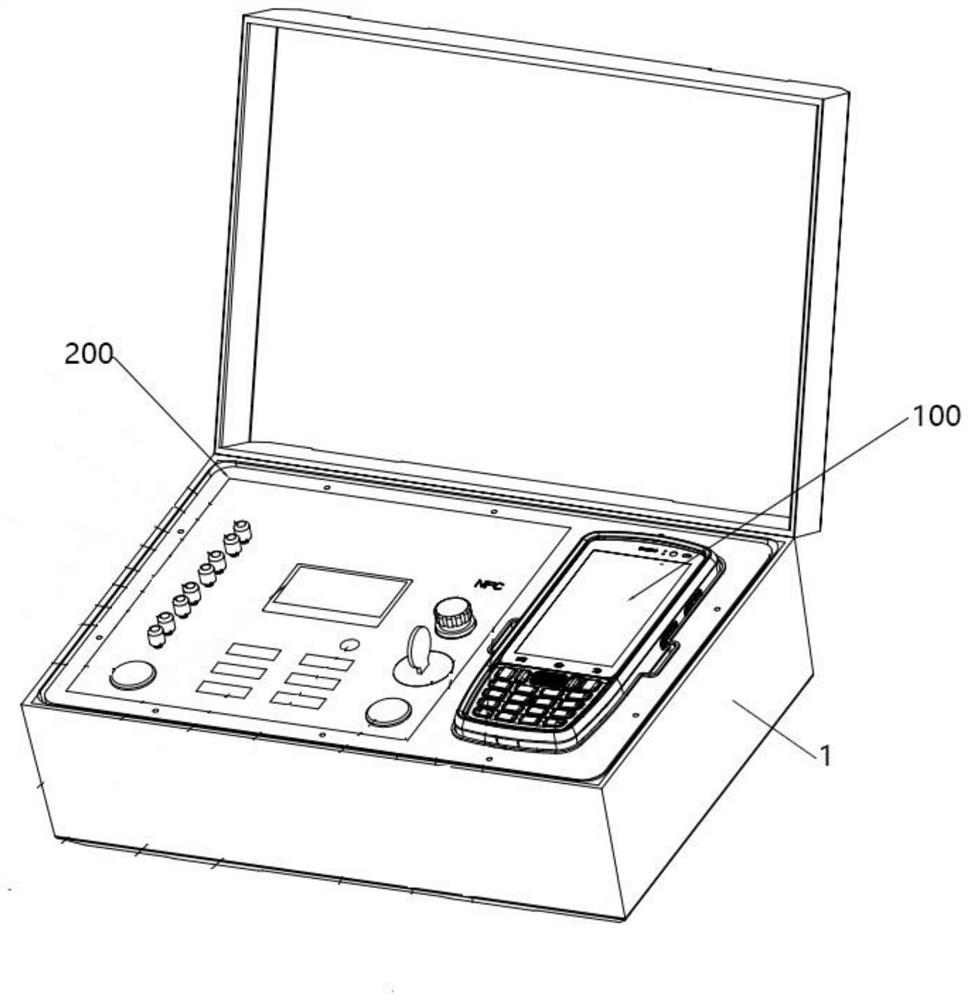

[0040] See figure 1 , 2 , an electronic detonator detonation device of the present invention, comprising a mobile programmer 100 and a detonation controller 200 connected by communication,

[0041] Mobile programmer 100 includes:

[0042] The scanning module 101 is used to scan the ID code of the detonator and obtain the UID information of the detonator. Each detonator at the blasting site has its own ID code. The two-dimensional code is a common form of the ID code. The ID code can be paper Paste it on the detonator pin line, and scan the UID information of the detonator in the blasting operation into the mobile programmer through the scanning module 101;

[0043] The programmer communication module 102 obtains the UID information according to the scanning module 101, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com