Continuous monitoring device and method for deformation of permanent steel formwork in construction period

A technology for monitoring devices and steel templates, applied in measuring devices, using optical devices, measuring heat, etc., can solve problems such as weak construction quality control, achieve the effects of guiding subsequent construction and maintenance, reducing economic losses, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

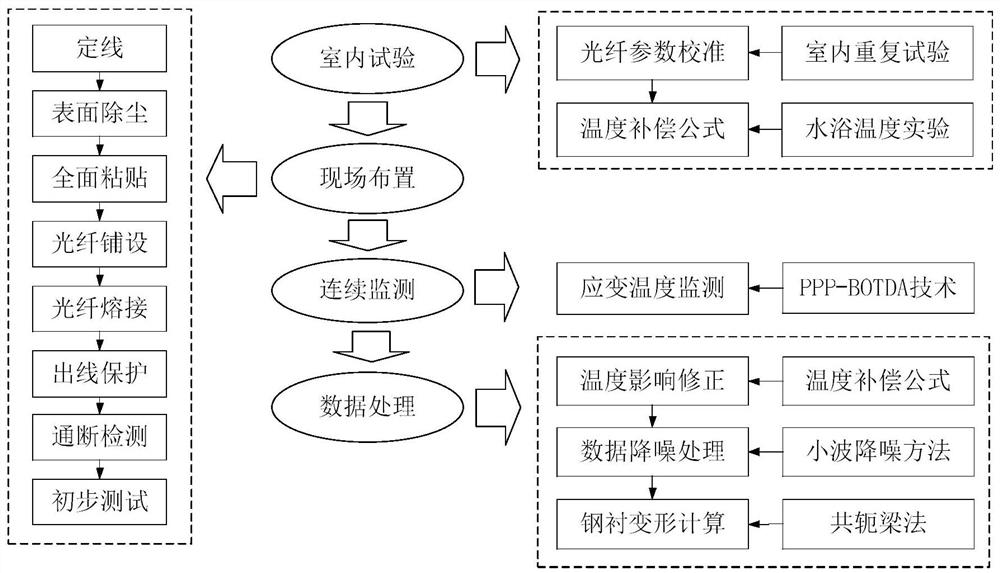

[0036] Below in conjunction with accompanying drawing, the present invention is described in further detail:

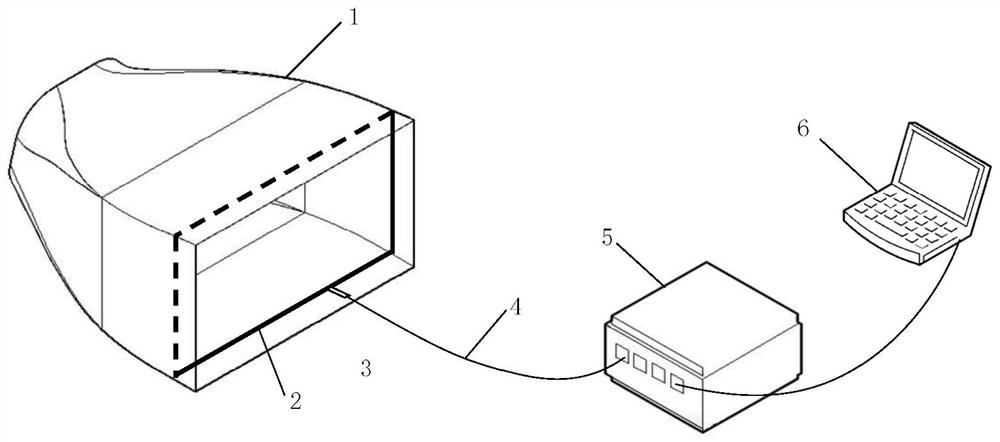

[0037] Such as figure 1 As shown, the present invention proposes a continuous monitoring device for permanent steel formwork deformation during construction, including: sensing optical fiber 2, protective fixture 3, communication optical fiber 4, optical nanometer 5, data processing terminal 6, and optical fiber fusion splicer, laser optical fiber Experimental tools such as test pens.

[0038] Sensing optical fiber 2 includes temperature sensing optical fiber and strain sensing optical fiber. Sensing optical fiber 2 is completely fixed to the monitoring surface of permanent steel template 1. Sensing optical fiber 2 is connected to photonometer 5 through communication optical fiber 4.

[0039] The protective clamp 3 is located at the outgoing position of the sensing optical fiber 2, and is used to protect the core of the sensing optical fiber 2 leading out.

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com