Multi-nut tightening torsion detection workbench

A technology for detecting workbench and torsion force, applied in the direction of measuring torque/torsion force during tightening, using stable torsion to test the strength of materials, measuring devices, etc., can solve problems such as single action, impact on production efficiency, and high labor intensity, and achieve The overall structure is simple, the effect of ensuring general use and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

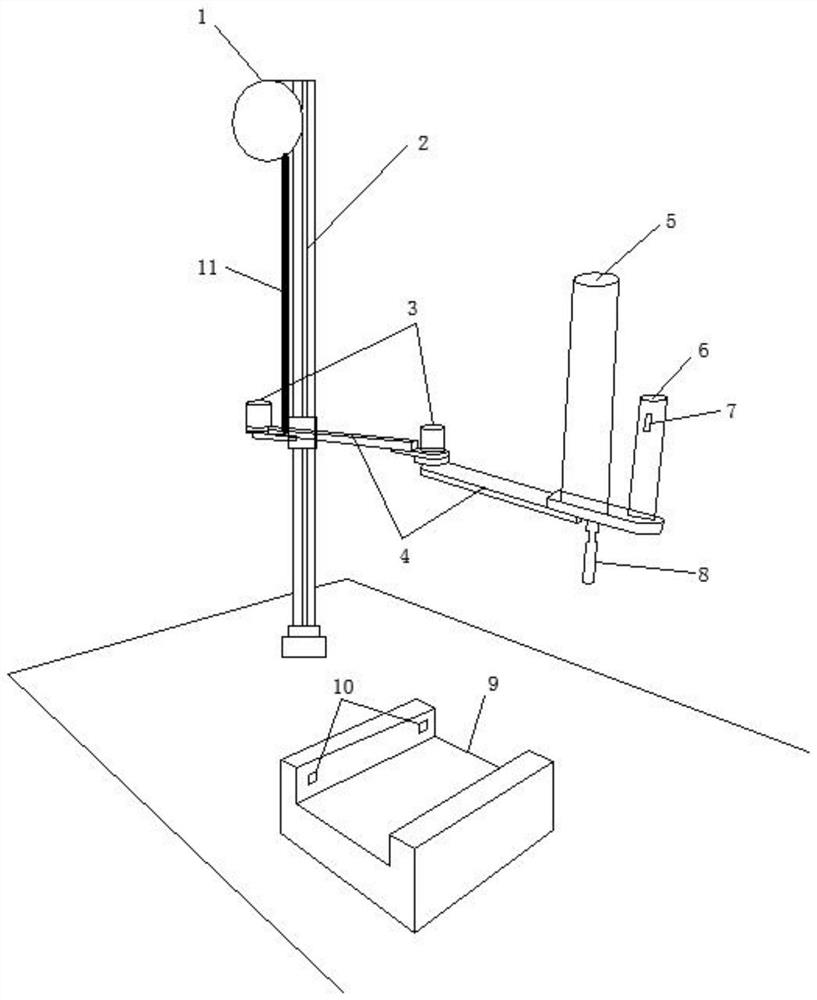

[0018] refer to figure 1 As shown, a multi-nut tightening torque detection workbench includes an adjustment carriage 2, a joint positioner 3, a mechanical arm 4, a tightening electric batch 5, an adjustment handle 6, a fixing jig 9, a cylinder lock 10 and a control device;

[0019] The adjustment slide frame 2 is vertically fixed on the installation cabinet, the adjustment slide frame 2 is provided with a retractable sliding crane 1, and the mechanical arm 4 is installed on the retractable sliding crane 1, and through the retractable sliding crane 1 Slide on the adjustment carriage 2; the mechanical arm 4 is composed of several joints, and the joints are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com