Object mass center measuring device and object mass center measuring method

A measuring device and object technology, applied in the field of object centroid measuring devices, can solve problems such as low measurement accuracy, and achieve the effects of improving measurement accuracy, improving measurement efficiency, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

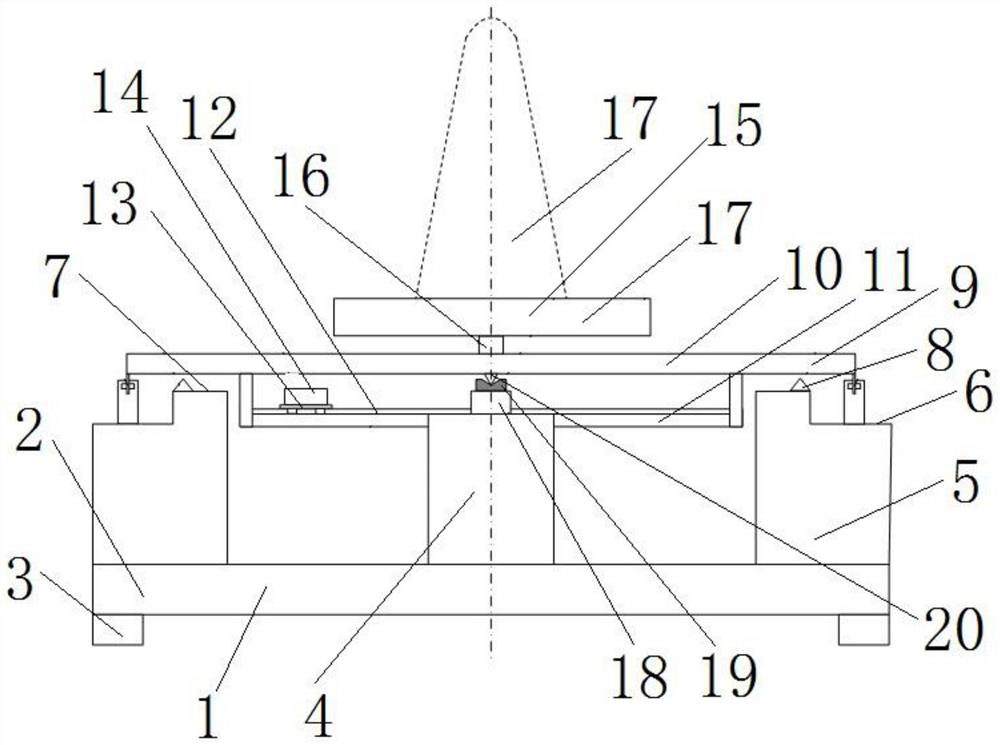

[0044] Such as figure 1 and figure 2 As shown, the object centroid measuring device includes a device base 1, on which an object bearing seat 9 and a balance detection device are arranged, the object bearing seat 9 is used for placing the object 17 to be measured, and the balance detection device is used to detect the position of the object bearing seat 9 Balanced state.

[0045] The device base 1 includes a rectangular bottom plate 2 , four support legs 3 are provided under the bottom plate 2 , and the four support legs 3 are respectively provided at the four corners of the bottom plate 2 to support the entire device base 1 . The length direction of the base plate 2 is the left-right direction, and the width direction of the base plate 2 is the front-rear direction.

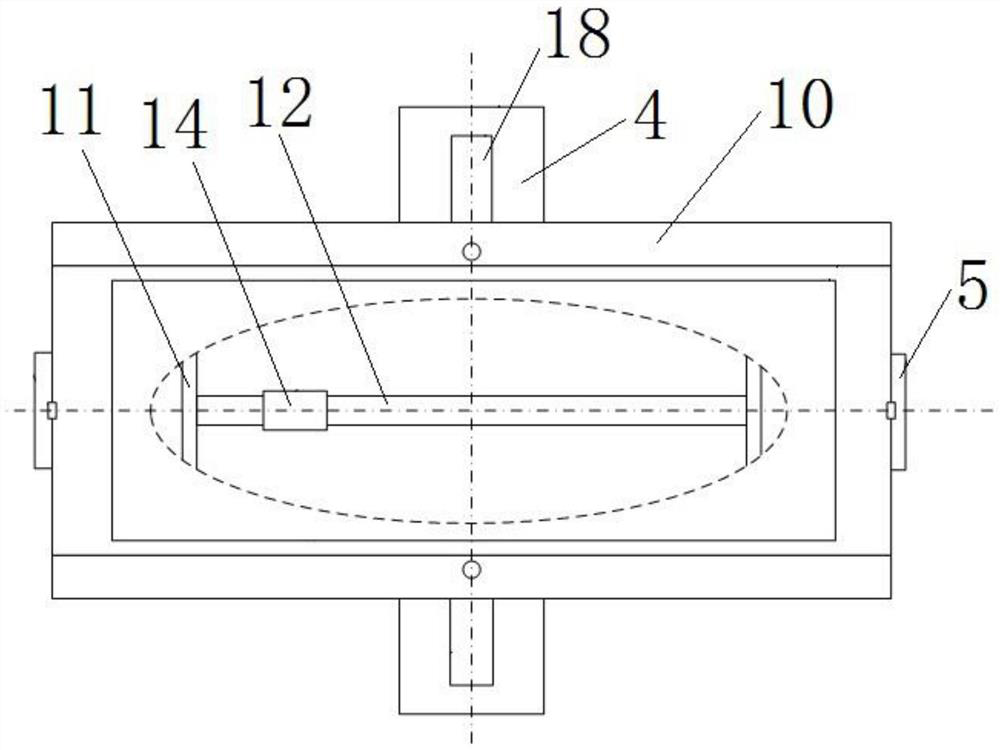

[0046] The object bearing seat 9 is a frame-mounted structure as a whole, including a seat body 10 and a weight bracket 11 .

[0047] The seat body 10 is a rectangular plate-shaped structure, and a turntable...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, a turntable 15 is provided on the object bearing seat 9, and the object to be measured 17 is placed on the turntable 15, and the difference of the object to be measured 17 can be measured by rotating the turntable 15. The centroid in the direction. And in the present embodiment, turntable is no longer set on the object bearing seat 9, and the object to be measured 17 is placed on the weight bracket 11 of sinking of the object bearing seat 9, in the present embodiment, to measure the parallel storage tank of aircraft 30 centroid as an example to introduce, such as Figure 4 Shown:

[0060] The seat body 10 of the object bearing seat 9 is provided with a through hole adapted to the shape of the parallel storage tank 30 for the parallel storage tank 30 to pass through the object bearing base 9 and be placed on the weight bracket 11 .

[0061] The weight bracket 11 is provided with an upper s...

Embodiment 3

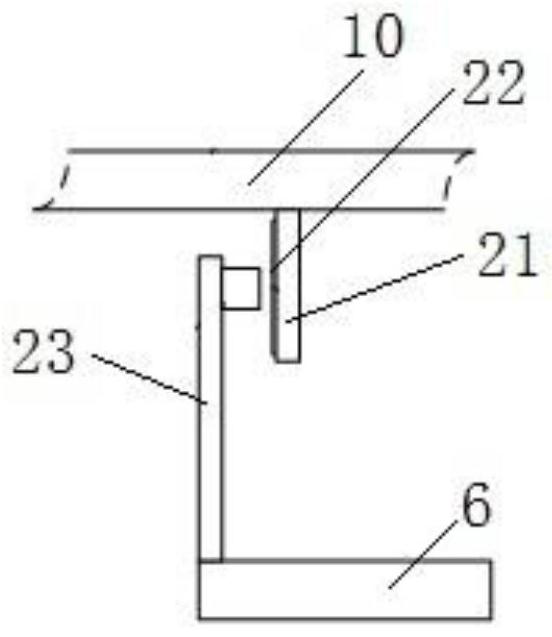

[0069] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, a linear motor module 13 is provided on the weight guide seat 12, a mover tray 14 is arranged on the linear motor module 13, and the weight is placed on the mover On the tray 14, the linear motor module 13 drives the mover tray 14 to move with the weight. In this embodiment, the mover tray 14 is directly guided to the assembly weight guide seat 12, a laser displacement sensor is set on the swing support table 4, and the mover tray 14 is manually moved, the value measured by the laser displacement sensor is the weight to The distance of the swing axis of the object bearing seat 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com