Off-line electric drive assembly NVH (Noise Vibration and Harshness) evaluation system and evaluation method

An evaluation system and electric drive technology, which is applied to measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of non-subjective evaluation, short sound memory time, system debugging and increased operating costs, etc., to achieve real-time output, reduce development cost, and shorten the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with embodiment.

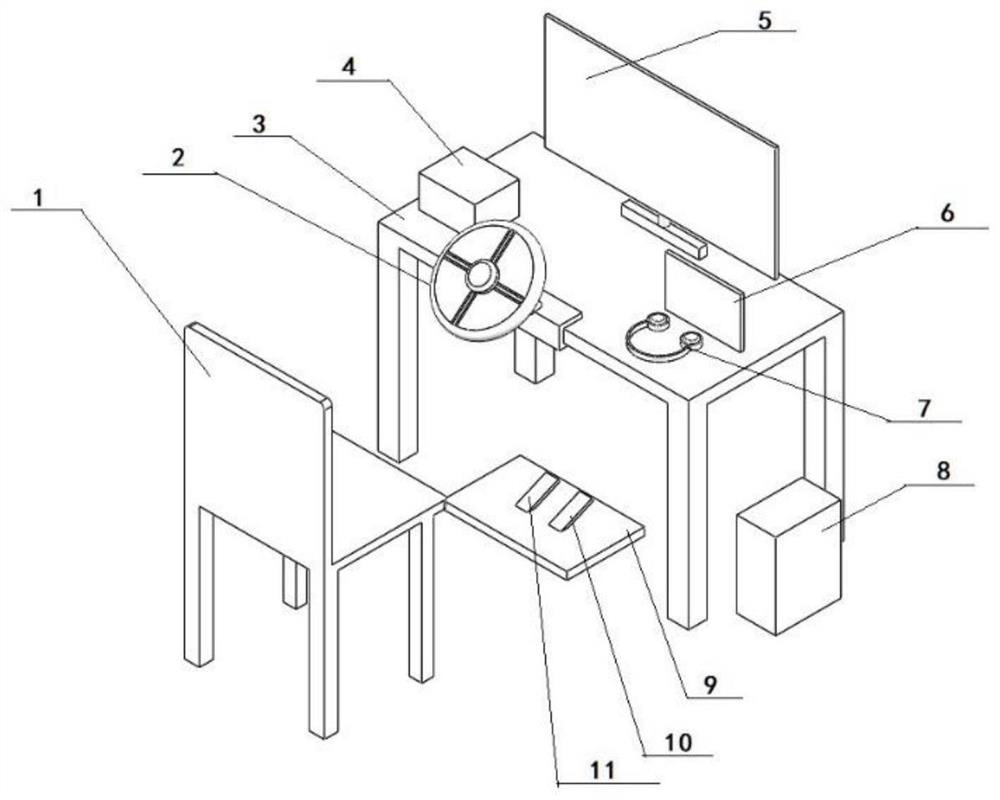

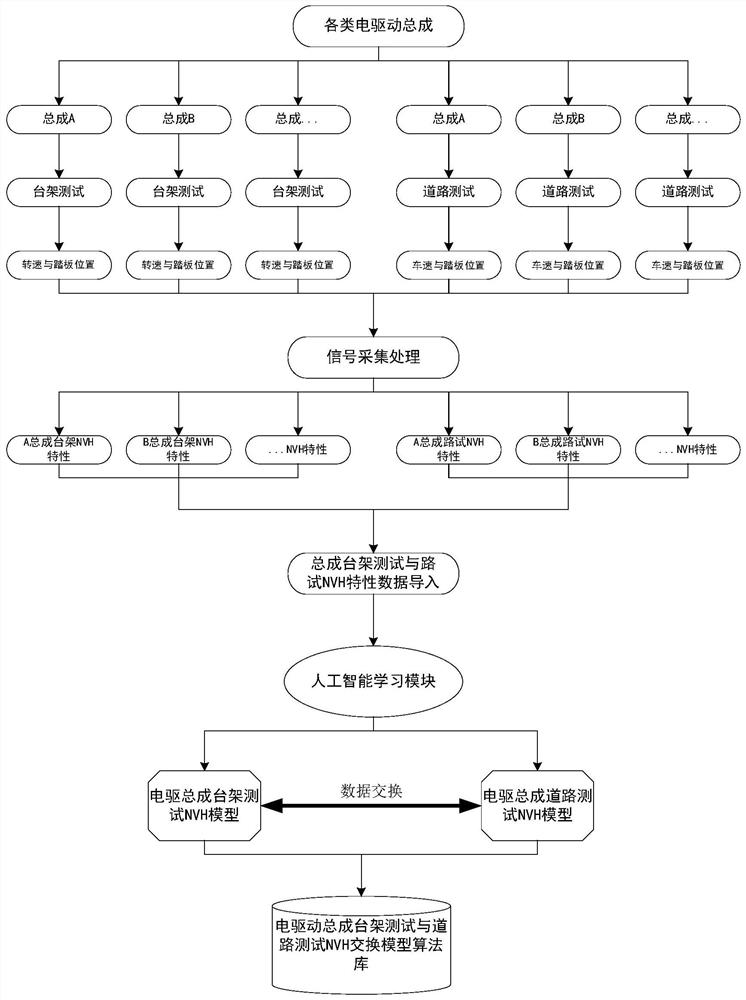

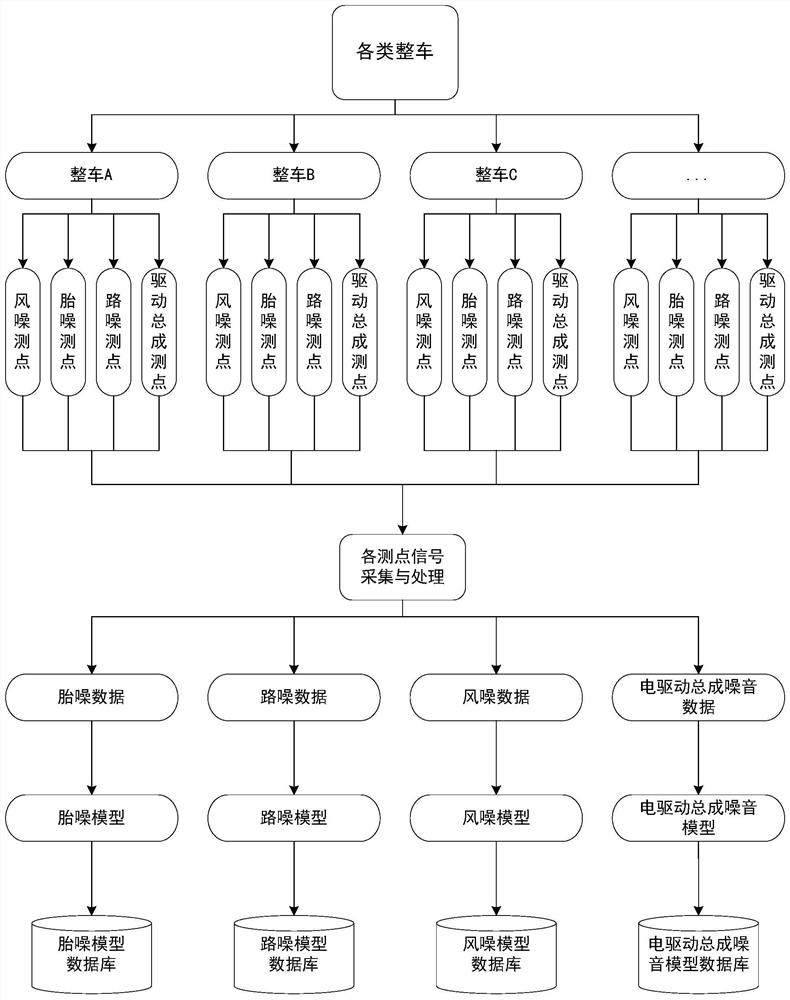

[0031] During specific implementation: if Figure 1 to Figure 6 As shown, an off-line electric drive assembly NVH evaluation system includes a data storage system, a driving simulation system and an audio-visual feedback system, and the data storage system includes a bench test for importing offline stored NVH bench test data database, the NVH bench test data includes rotational speed, load and corresponding NVH characteristic data; the simulated driving system includes a driving control module and a driving simulation module, the driving control module includes a brake pedal, an accelerator pedal and a steering wheel, the The driving simulation module is used to receive the control signal from the driving control module to calculate the real-time speed and load of the electric drive assembly, and transmit the real-time speed and load to the bench test database; the bench t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com