Ultrasonic guided wave detection device for damage of steel structure process equipment and use method of ultrasonic guided wave detection device

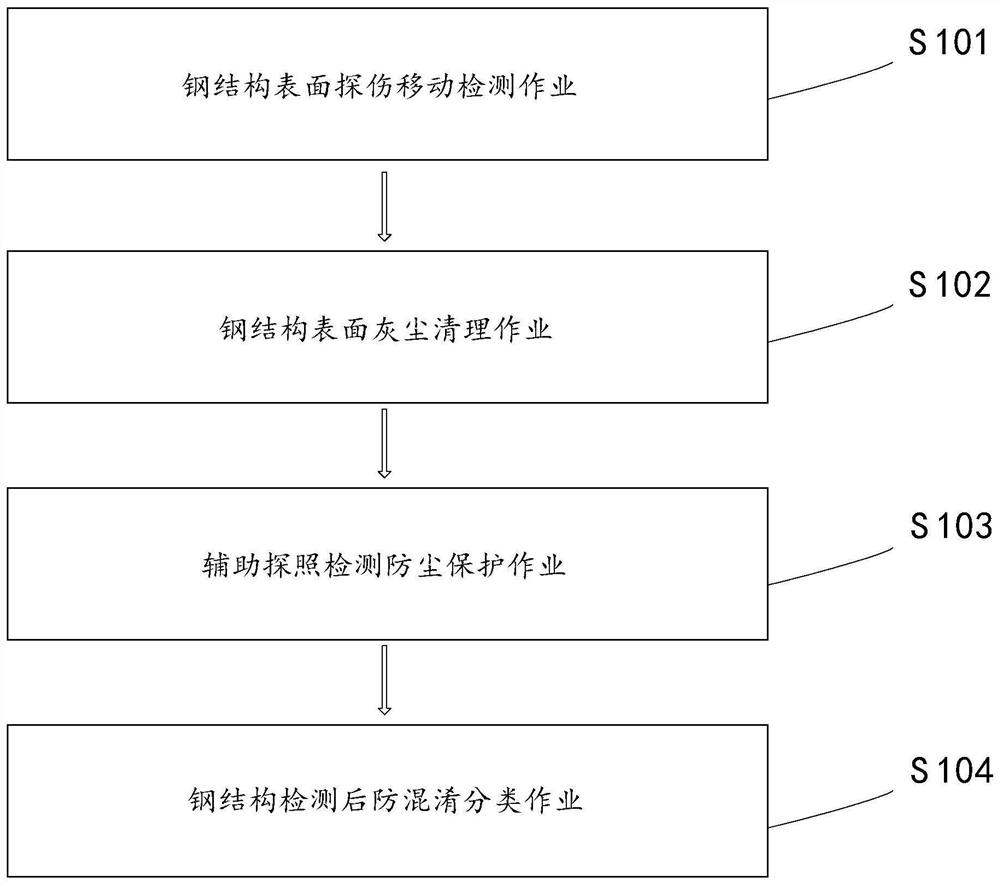

A technology of ultrasonic guided wave and process equipment, which is applied in the direction of measuring devices, cleaning methods using tools, and using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., which can solve the problems of labeling anti-confusion, affecting detection effects, and damage detection dust protection effects and other problems, to achieve the effect of ensuring the stability of detection, ensuring accuracy, and being easy to find

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

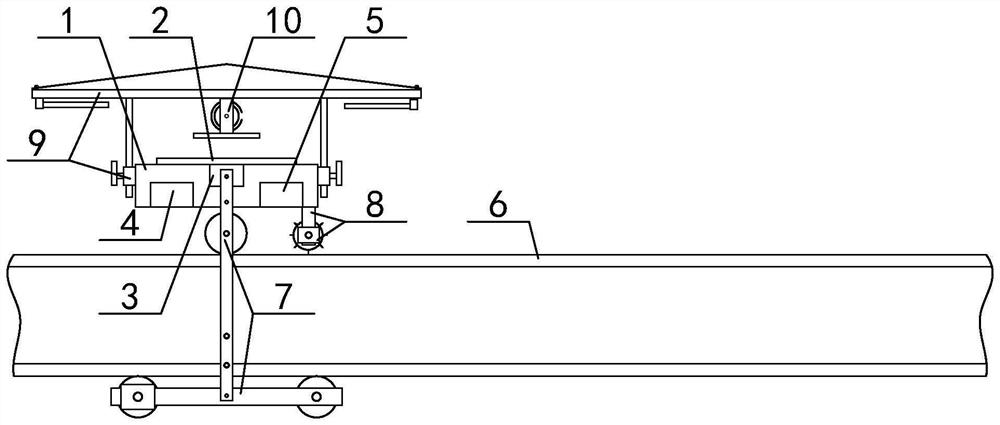

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] In the picture:

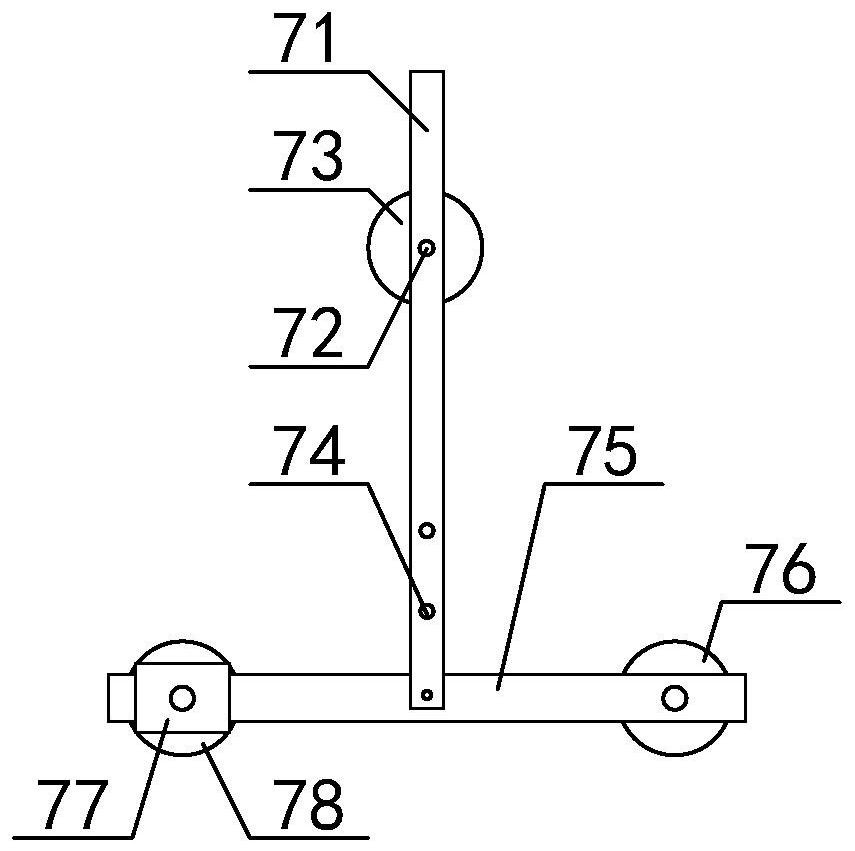

[0030] as attached figure 2 to attach Image 6 shown

[0031] An ultrasonic guided wave detection device for steel structure process equipment damage, including a detection cover 1, a main board 2, a battery 3, an ultrasonic generator 4, a vibration frequency receiver 5, a steel structure body 6, and an adjustable steel structure surface movable frame structure 7 , steel structure surface dust cleaning wheel structure 8, auxiliary searchlight dustproof protection plate structure 9 and steel structure detection anti-confusion marking wheel structure 10, the upper surface of the detection cover 1 is connected with a main board 2 by screws; the detection cover 1. A battery 3 is screw-connected to the middle part of the inner top; the left and right ends of the inner lower part of the detection cover 1 are screw-connected with an ultrasonic generato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com