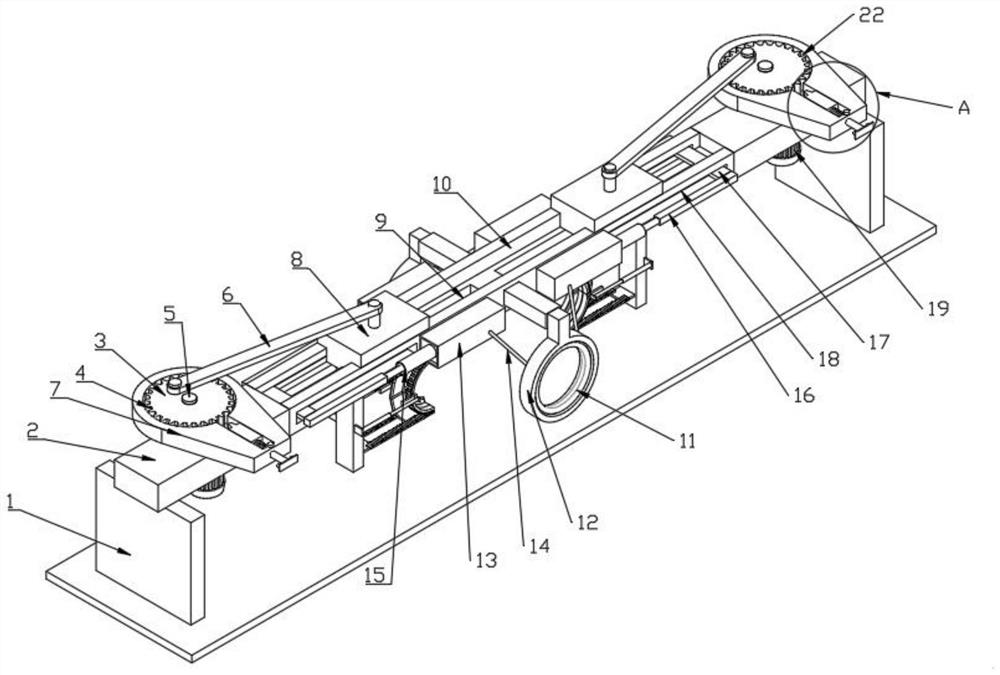

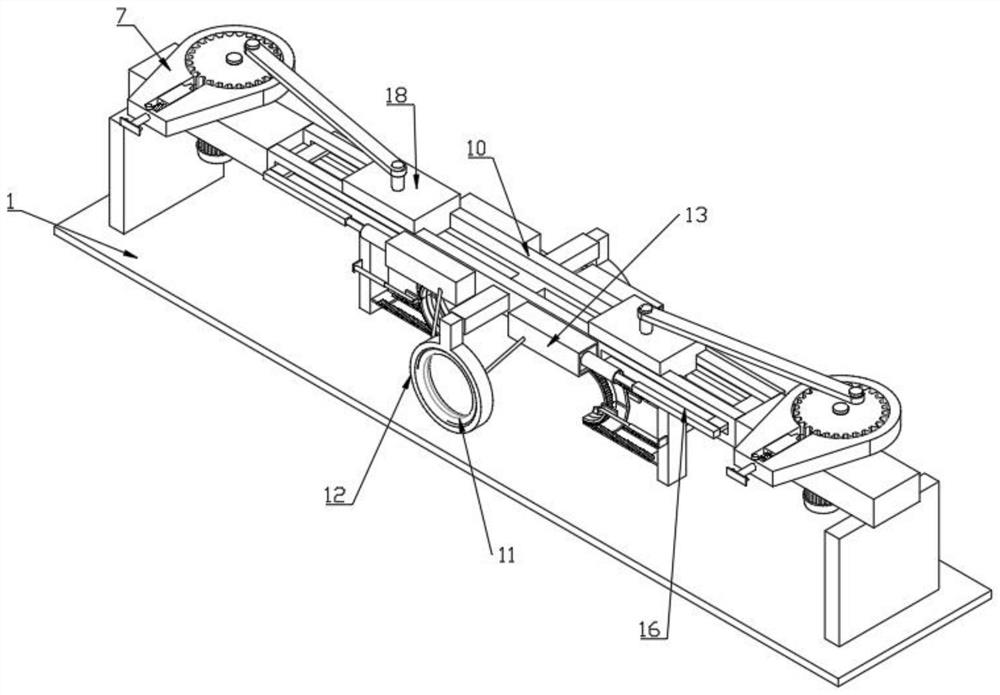

Full-automatic pipe cutting machine for endoscope wire production

An endoscope and fully automatic technology, which is applied in the direction of pipe shearing device, shearing device, shearing machine accessory device, etc., can solve the problem of low safety performance, high requirements for the production process of endoscope wire and cable, and endoscope It can improve the safety performance, improve the scope of use, and keep the cutting position stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

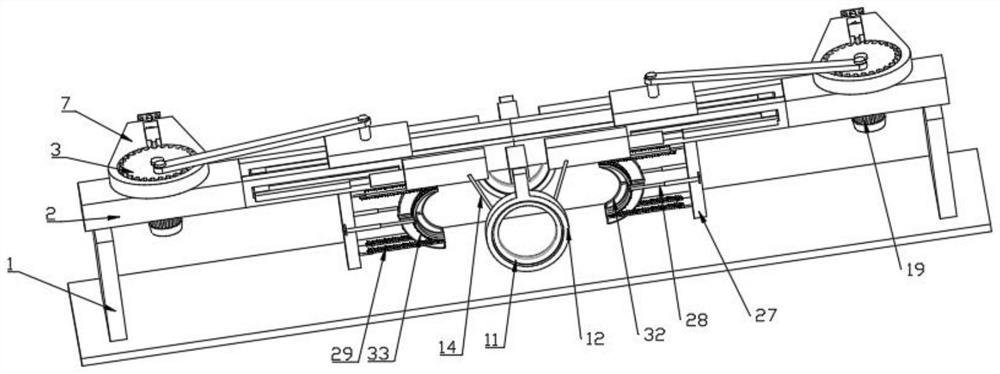

Embodiment 1

[0032] Embodiment 1, as a way to drive the movable block 21 to move, the other end of the movable block 21 is fixedly installed with a movable column 25, and one end of the movable column 25 away from the movable block 21 extends to the outer wall of the mounting plate 7, and the movable block 21 is connected to the mounting plate 7. A spring 23 is sleeved on the outer wall of the movable column 25 between the plates 7 .

[0033] When the entire endoscope wire needs to be cut, so that the limit post 24 and the movable post 25 are released from the limit, at this time, under the elastic force of the spring 23, the movable block 21 can drive the clamping block 20 to approach the clamping slot. 4 moves, when the movable block 21 drives the clamping block 20 to move toward the end close to the clamping slot 4, the fixed plate 2 and the installation plate 7 can be fixed as a whole.

[0034] Further, a limit post 24 for locking the movable post 25 is movably mounted on the mounting pl...

Embodiment 2

[0038] Embodiment 2, as another way to drive the movable block 21 to move, further, the end of the movable block 21 is further provided with a second electric telescopic rod 35, and the second electric telescopic rod 35 is used to drive the clamping block 20 and the clamping slot. 4 snaps.

[0039] The second electric telescopic rod 35 and the first electric telescopic rod 28 are independently controlled to work by the single chip microcomputer. When the second electric telescopic rod 35 works, the clamping block 20 can be driven to engage with the clamping slot 4, so that the fixed plate 2 and the installation plate 7 are engaged. In order to be fixed as a whole, at the same time, the first electric telescopic rod 28 works to drive the two arc-shaped plates 30 to move away from each other, so as to realize the integral cutting of the endoscope wires.

[0040] Further, two sets of limit clamping mechanisms are also fixed in the middle of the mounting frame 10 , each set of lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com