Intelligent production line pin penetrating unit

A pin, linear motion technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of slow speed, low production efficiency, manual reclaiming, etc., to save power components, improve operating speed, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

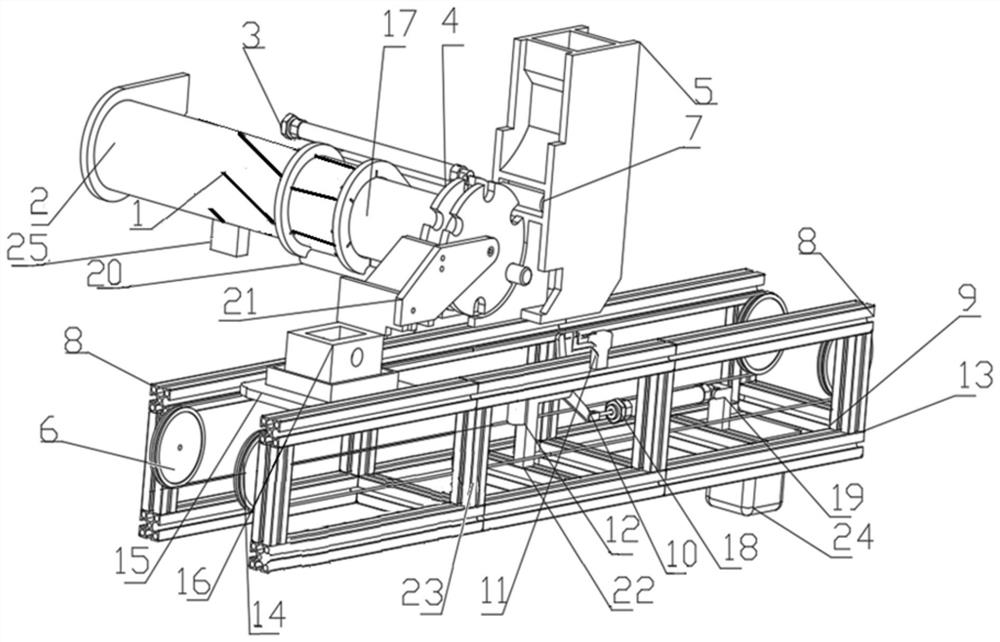

[0029] see figure 1 , The pin-threading unit proposed by the present invention includes a pin-threading part and a conveying part. Among them, the pin-threading part is mainly responsible for inserting the pin into the part 16 to be processed to complete the assembly of the pin 7 and the part; the transmission part is mainly responsible for transporting the part to the designated position through the pallet 15, and continues after the pin assembly is completed at the designated position. Delivery, that is, by controlling the stop and movement of the parts, the parts are stopped before being pinned and moved after being pinned.

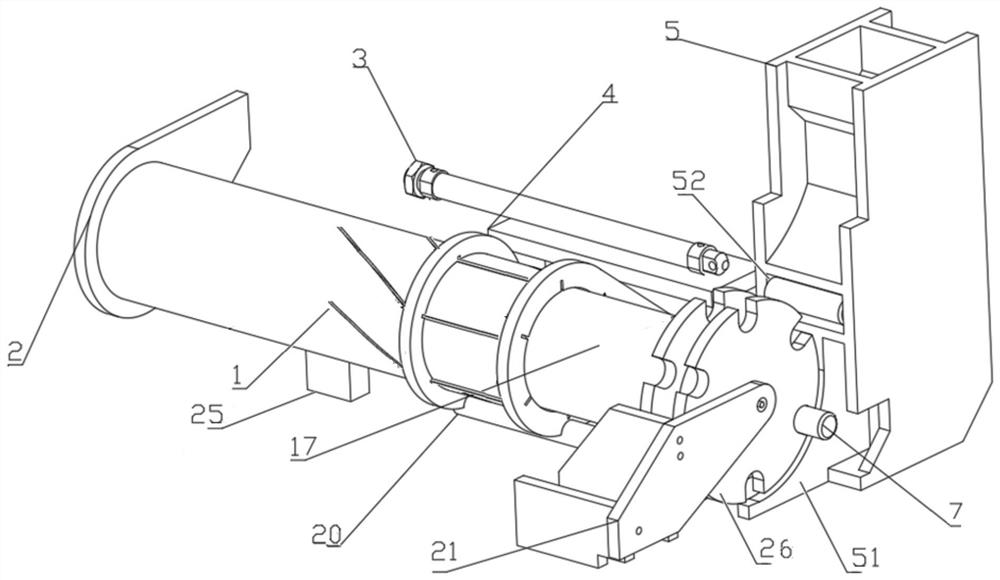

[0030] see figure 2 , the pin-threading part includes a push rod 20, a pin assembly cylinder 3 (referred to as the pin cylinder), a cam rotation mechanism and a stocker 5. The accumulator 5 includes a box-shaped housing and a lateral support frame 4 connected to the lower part of the housing. The pin assembly cylinder 3 is installed on the lateral ...

Embodiment 2

[0044] Different from Embodiment 1, the transmission motor 24 is a linear motor.

Embodiment 3

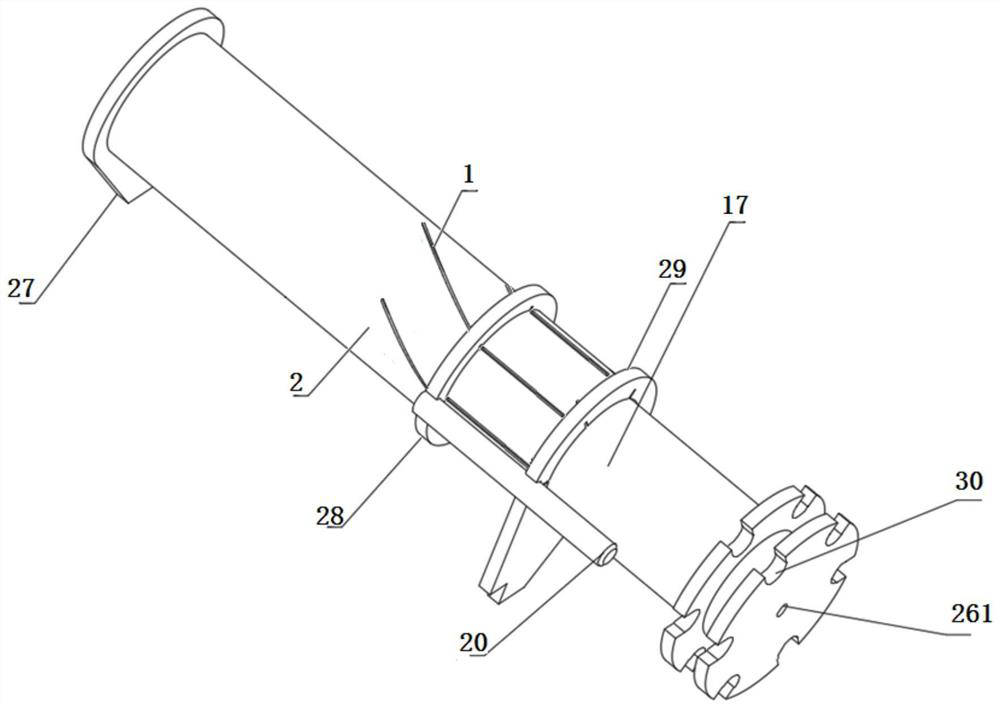

[0046] For the process of the push rod 20 returning to its original position (moving backward) with the slip ring 28 in Embodiment 1, if the inner cylinder 17 rotates counterclockwise when the slip ring 28 passes through the chute, the baffle plate can be used to Parts on 21, such as a pawl-like structure, prevent the rotation of the inner cylinder 17, thereby preventing the turntable 26 from rotating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com