Mechanical automatic machine tool security and protection device

A technology for driving devices and machine tools, which is applied to metal processing machinery parts, maintenance and safety accessories, and large fixed members, etc. It can solve the problems of scattered impurities, pollution, and inability to filter impurities, so as to improve the use effect, reduce decibels, and facilitate separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

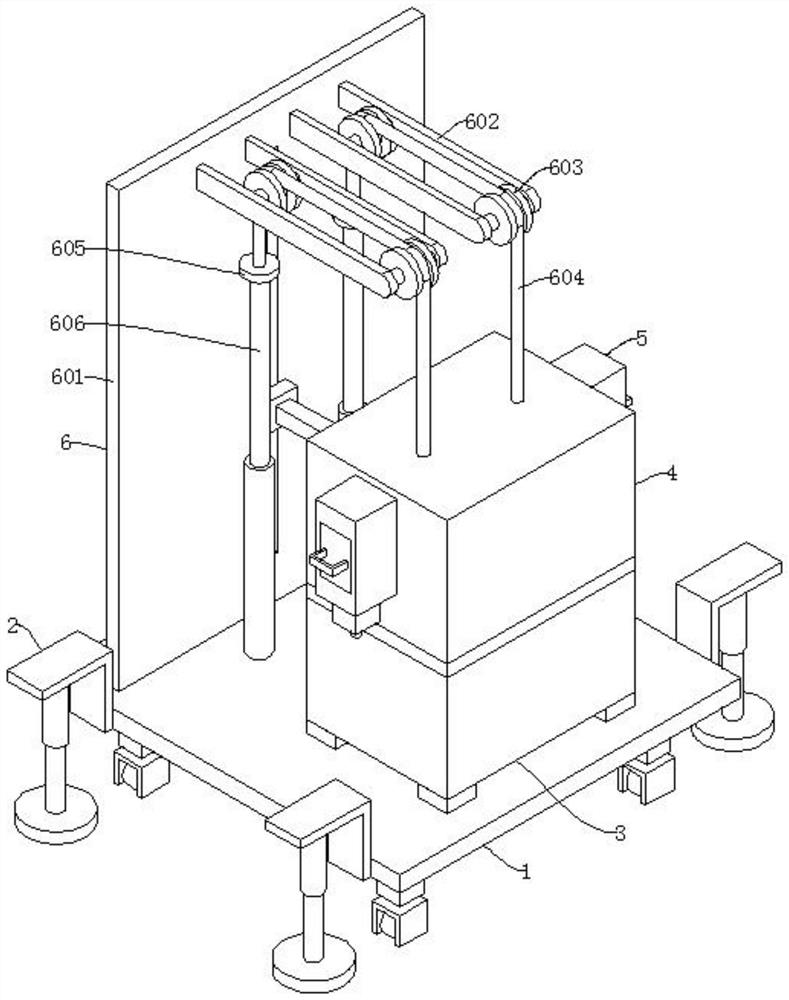

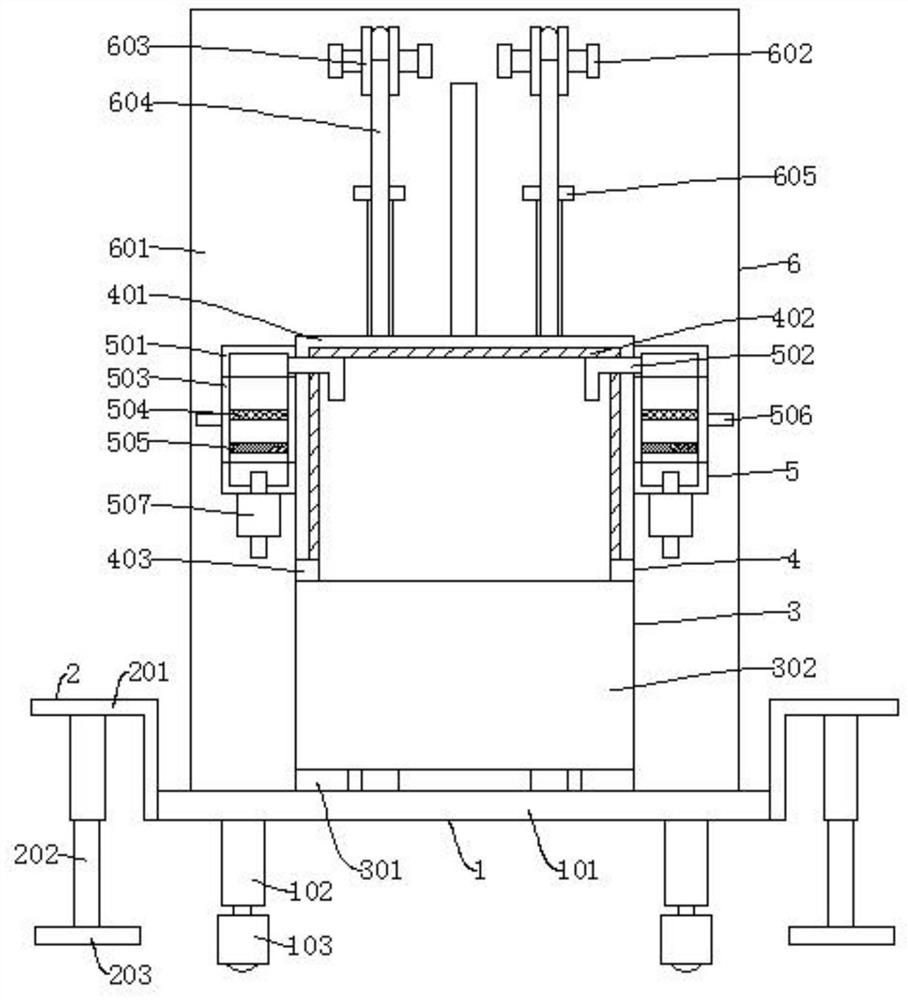

[0050] Such as figure 1 , image 3 , Figure 5 , Figure 7 , Figure 8 As shown, a security device for a mechanical automation machine tool includes a moving mechanism 1 for driving the device to move, a fixing mechanism 2 for fixing the device, and a processing mechanism 3 for processing workpieces. The moving mechanism 1 is installed on both sides There is a fixed mechanism 2, and a processing mechanism 3 is fixed above the moving mechanism 1, which also includes a protective mechanism 4 for preventing noise and dust from endangering human health, a filtering mechanism 5 for filtering dust, and a mechanism for driving the protective shell 401 up and down. The lifting mechanism 6, the protective mechanism 4 is arranged above the processing mechanism 3, the filter mechanism 5 is fixed on both sides of the protective mechanism 4, and the lifting mechanism 6 is arranged at the rear of the protective mechanism 4;

[0051] The protective mechanism 4 includes a protective shell...

Embodiment 2

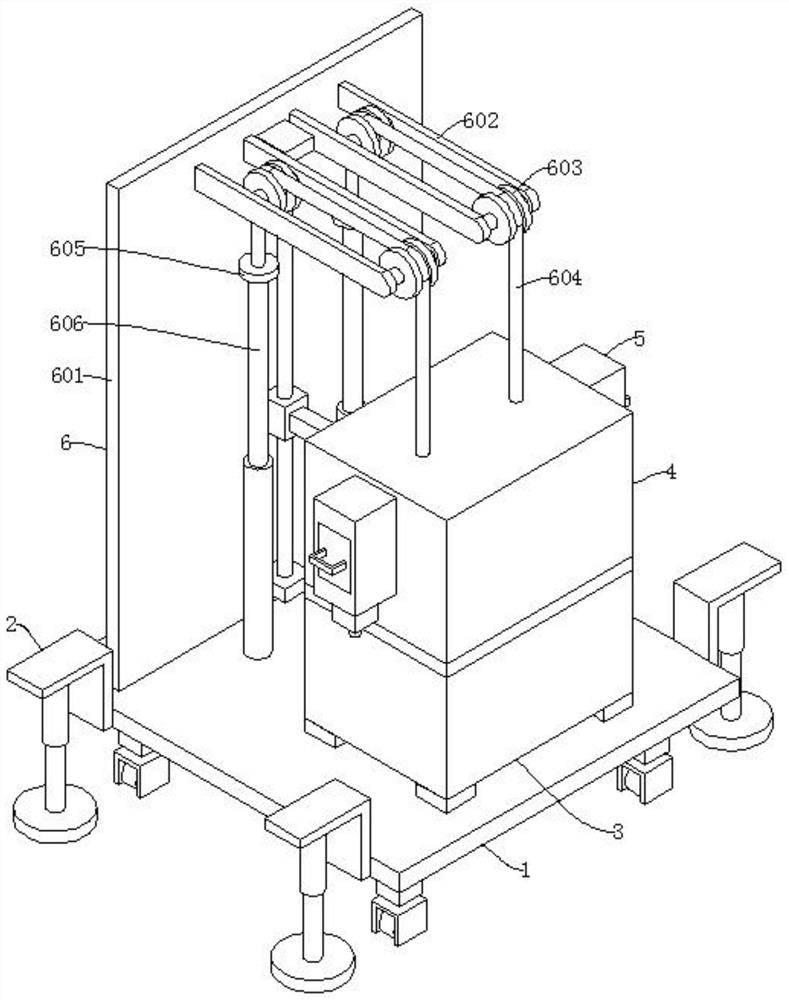

[0057] Such as figure 2 , Figure 4 , Figure 6 , Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the first vertical plate 6011, the guide hole 6012, the lifting seat 6013, and the first lifting rod 6014 are replaced by the second vertical plate 6015, the guide rod 6016, the end plate 6017, When the lifting sleeve 6018, the second lifting rod 6019, and the internal parts of the protective shell 401 need maintenance, start the second electric push rod 606, and the second electric push rod 606 shrinks to drive the connecting block 605 to descend, and the connecting block 605 descends to drive the traction rope 604 Move, the traction rope 604 drives the protective shell 401 to rise, and the protective shell 401 drives the lifting sleeve 6018 to rise along the guide bar 6016 through the second lifting rod 6019. After the protective shell 401 rises to a certain height, the internal parts can be repaired and maintained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com