Test block vibrating device and assembling method thereof

A technology of vibrating device and assembling method, applied in the preparation of test samples, ceramic molding machines, manufacturing tools, etc., can solve the problems of high noise, difficult cleaning, inability to vibrate uniformly, etc., and achieve the effect of less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

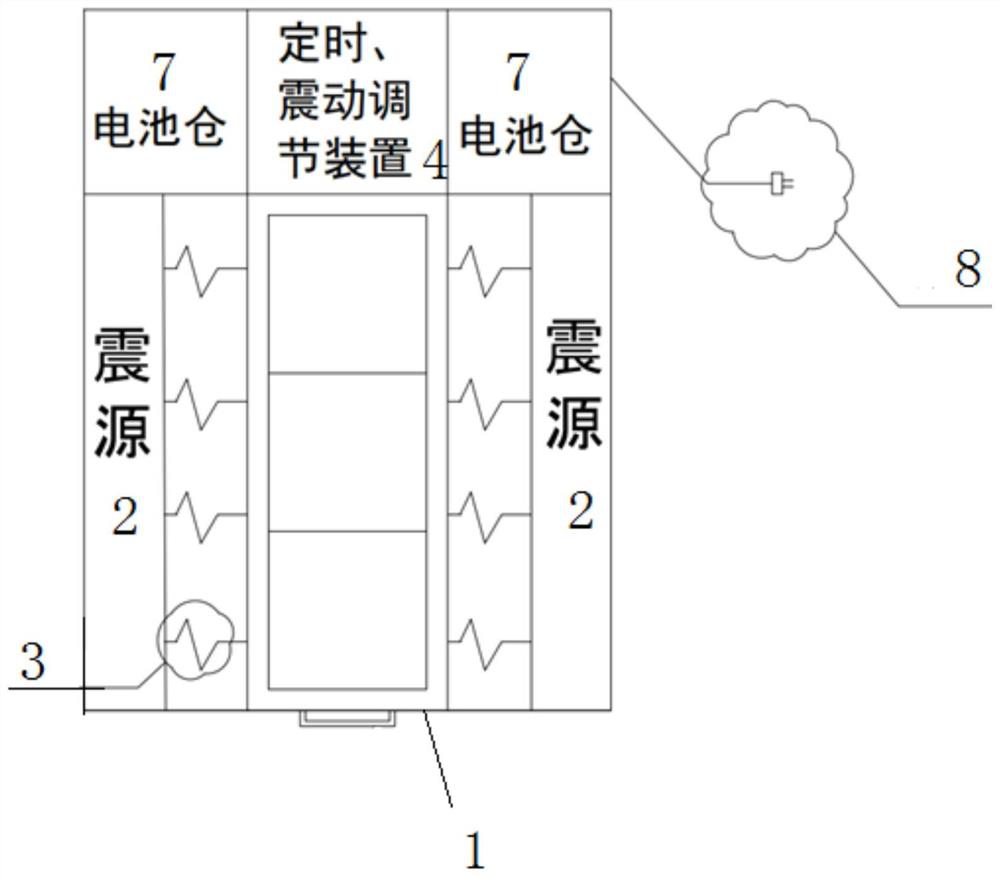

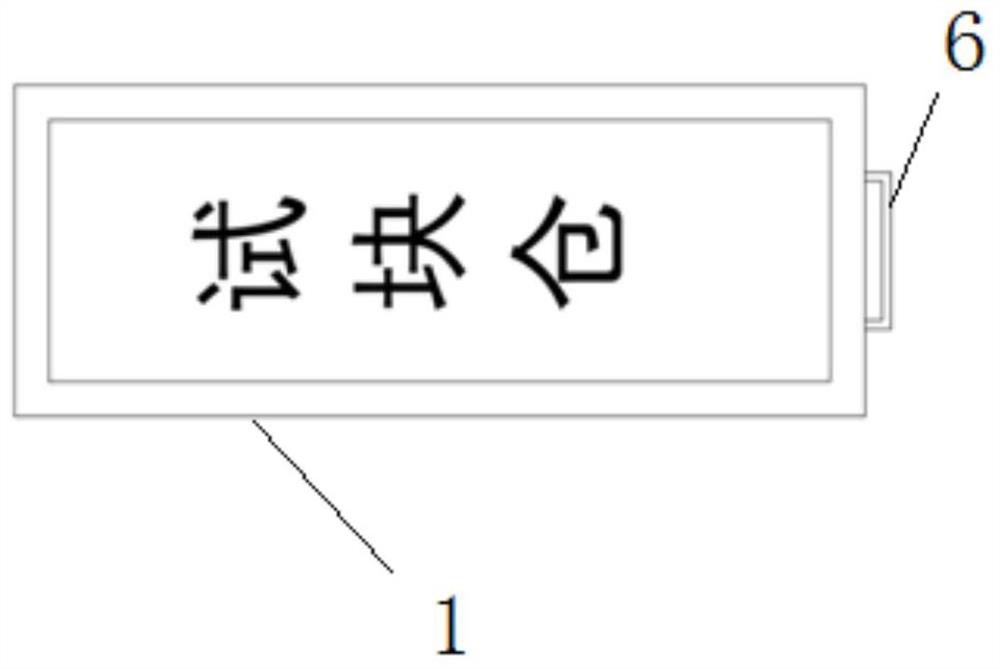

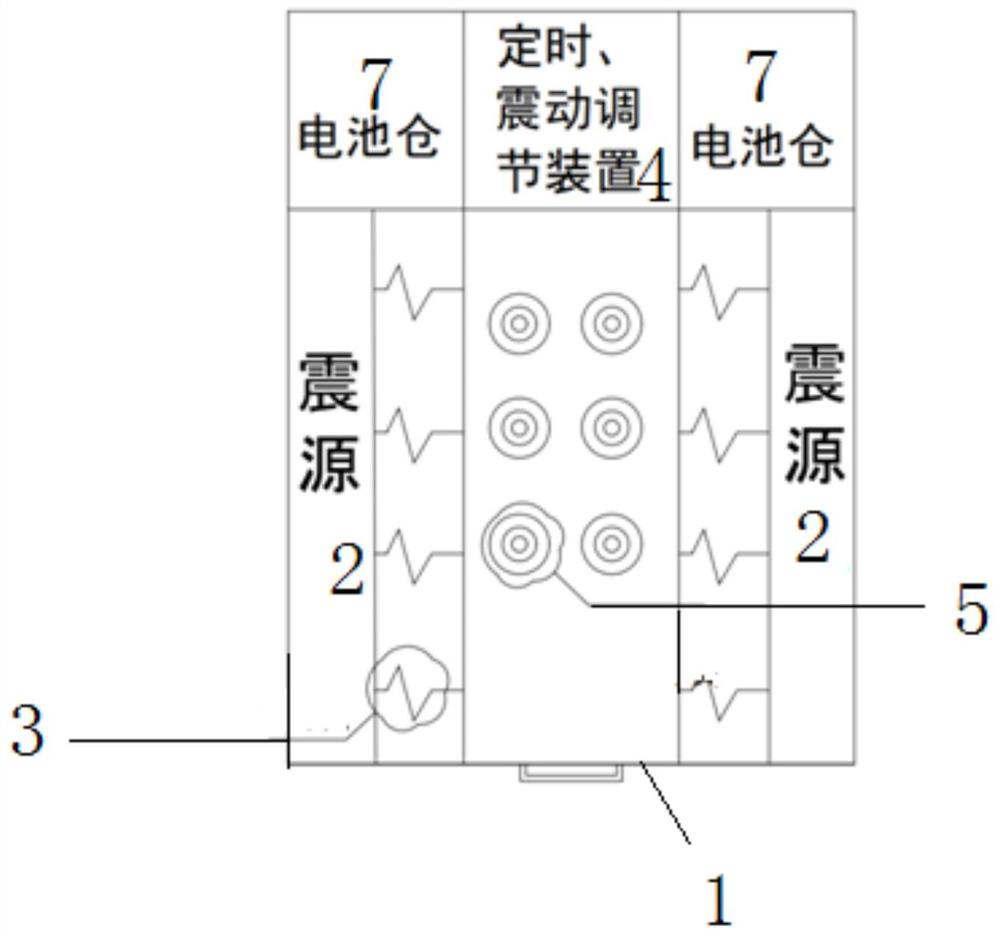

[0030] Such as Figure 1~3 As shown, the present invention provides a kind of test block vibrating device, comprising:

[0031] A vibration chamber, the vibration chamber includes: a test block chamber 1, a shock source 2 and a side spring 3, one end of the side spring 3 is connected to the test block chamber 1, and the other end of the side spring 3 is connected to the shock source 2;

[0032] Timing and vibration adjustment device 4, the timing and vibration adjustment device is connected with the vibration source device.

[0033] Here, this device aims to make a small and convenient electronic vibrating device to solve the problems of traditional vibrating tables. The device is equipped with a timing device, and the mold can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com