Traction device for large-size pipe fitting

A traction device and large-scale technology, applied in the traction field, can solve the problems of single transportation mode, inconvenient protective running structure, pipe fittings detaching from device control, etc., and achieve the effects of improving stability, maintaining stability and avoiding deflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

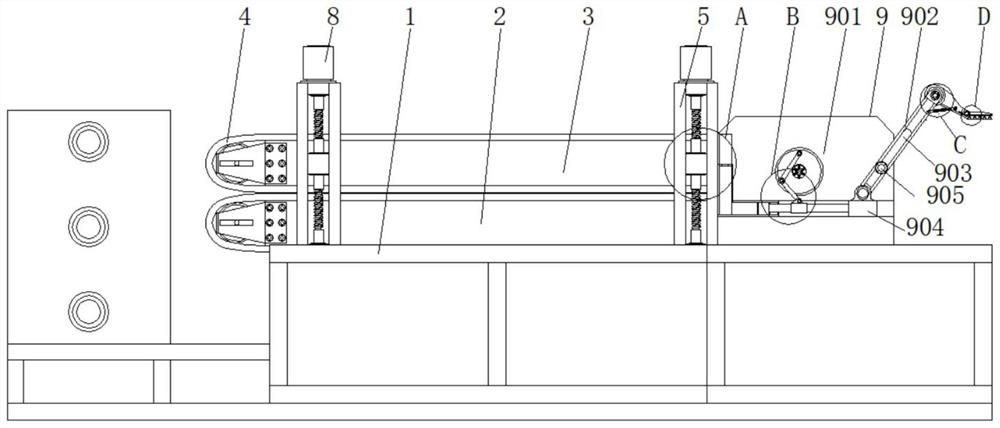

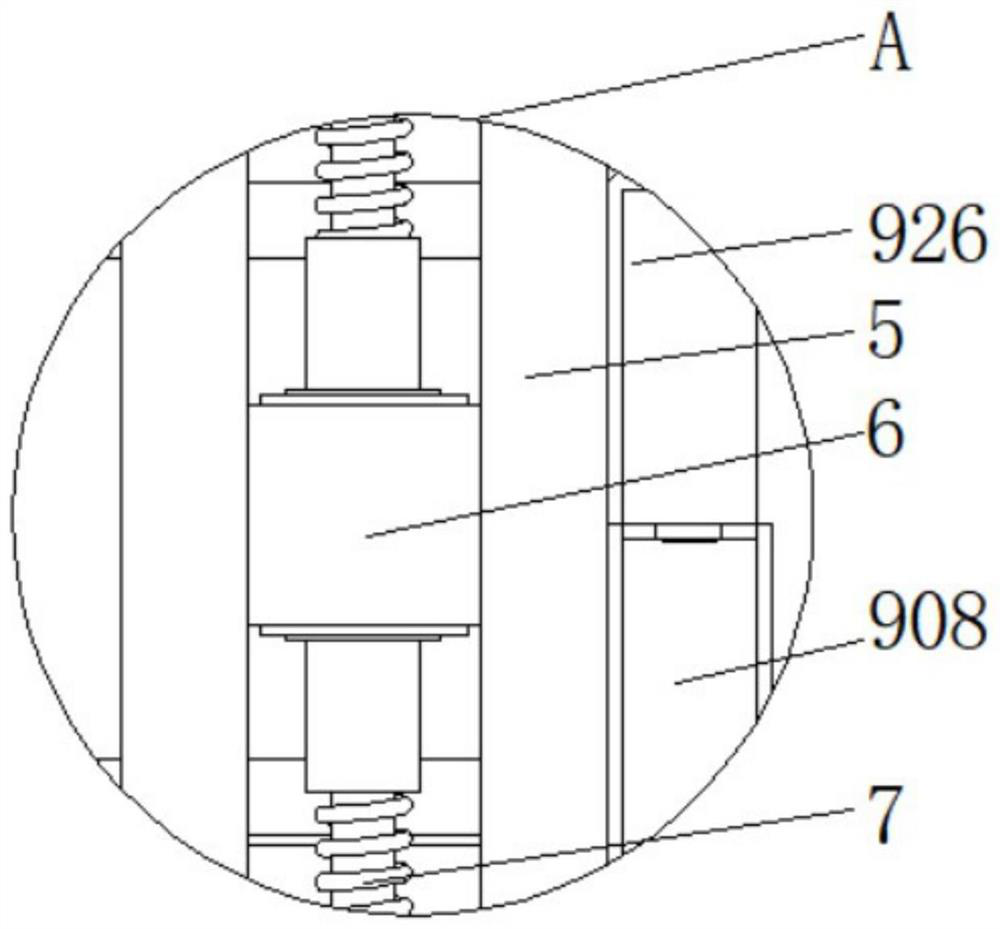

[0029] like figure 1As shown, this embodiment proposes a traction device for large-sized pipe fittings, including a bottom support cabinet frame 1, a bottom transmission mechanism 2 installed on the bottom support cabinet frame 1, a fixed frame 3 installed on the bottom transmission mechanism 2, And the conveyor belt 4 installed on the fixed frame 3, two groups of position adjustment mechanisms are arranged on both sides of the fixed frame 3, each group has two, and the position adjustment mechanism includes a guide frame 5, a guide fixed block 6, an adjustment screw rod 7 and a linear wire The rod motor 8 and the guide frame 5 are fixed on the bottom supporting cabinet frame 1 by bolts, the guide frame 5 is provided with an adjusting screw 7, and the input end of the adjusting screw 7 is connected with a linear screw motor 8, and the linear screw motor Under the action of 8, the guide fixing block 6 can be moved along the central axis direction of the guide frame 5 by adjusti...

Embodiment 2

[0031] The solution in Embodiment 1 will be further introduced in combination with specific working methods below, see the following description for details:

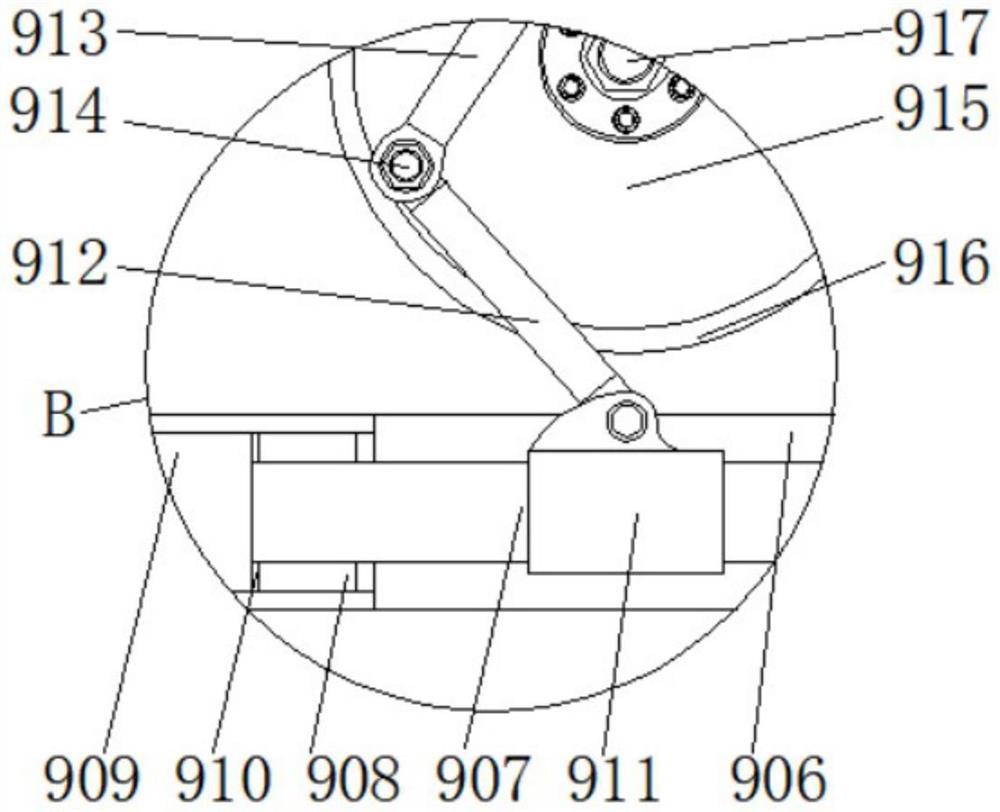

[0032] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, as a preferred embodiment, on the basis of the above method, further, the auxiliary traction and pushing mechanism 9 includes an installation frame 901, a support arm 902, a chute 903, an adjustment guide block 904, a fixed sliding pin 905, and a transverse chute 906, connecting slide bar 907, cavity post 908, piston block 909, rubber gasket 910, fixed sleeve post 911, connecting strut 912, adjusting strut 913, connecting pin 914, turntable 915, ring frame 916, drive motor 917 , pressing plate 918, fixed shaft 919, connecting spring 920, wear-resistant rubber pad 921, pull plate 922, return coil spring 923, lock shaft 924, suction cup 925 and rubber airbag 926, and the bottom supporting cabinet frame 1 is provided with an installation fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com