Diamond annular wire weaving equipment

A circular thread and diamond technology, applied in the direction of braided fabrics, twisted lace looms, textiles and papermaking, etc., can solve the problems of unsatisfactory use requirements, low quality of manual operation, difficult weaving, etc., and achieve stable and reliable product quality. Improve the preparation efficiency and the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example 1:

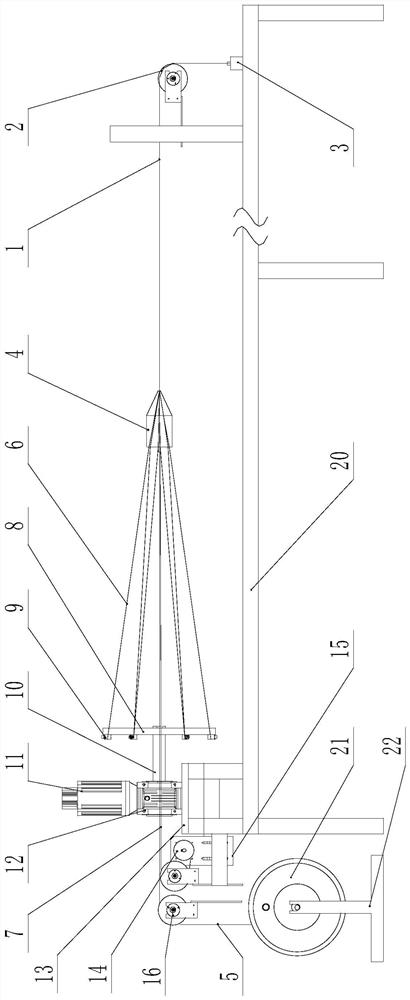

[0026] Such as Figure 1-2 As shown, a diamond ring line fabrication apparatus includes a rack 20, and a rotating mechanism, a tap mechanism, a winding mechanism, a tensioning mechanism, a spindle adjustment assembly 4 and a steel core line 5 are provided. The rotating mechanism is connected to the winding mechanism, the tandem mechanism is connected to the twist adjustment assembly 4, and the steel core wire 5 is mounted on the tensioning mechanism, and the steel core 5 sequentially passes through the rotating mechanism, the winding mechanism, and the spatulation adjustment. Component 4.

Example Embodiment

[0027] Example 2:

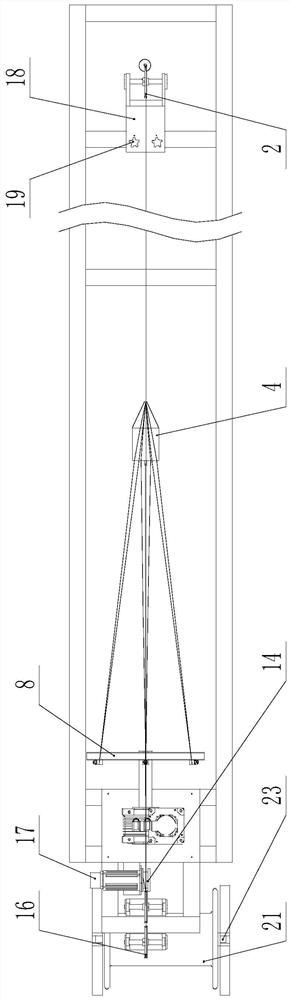

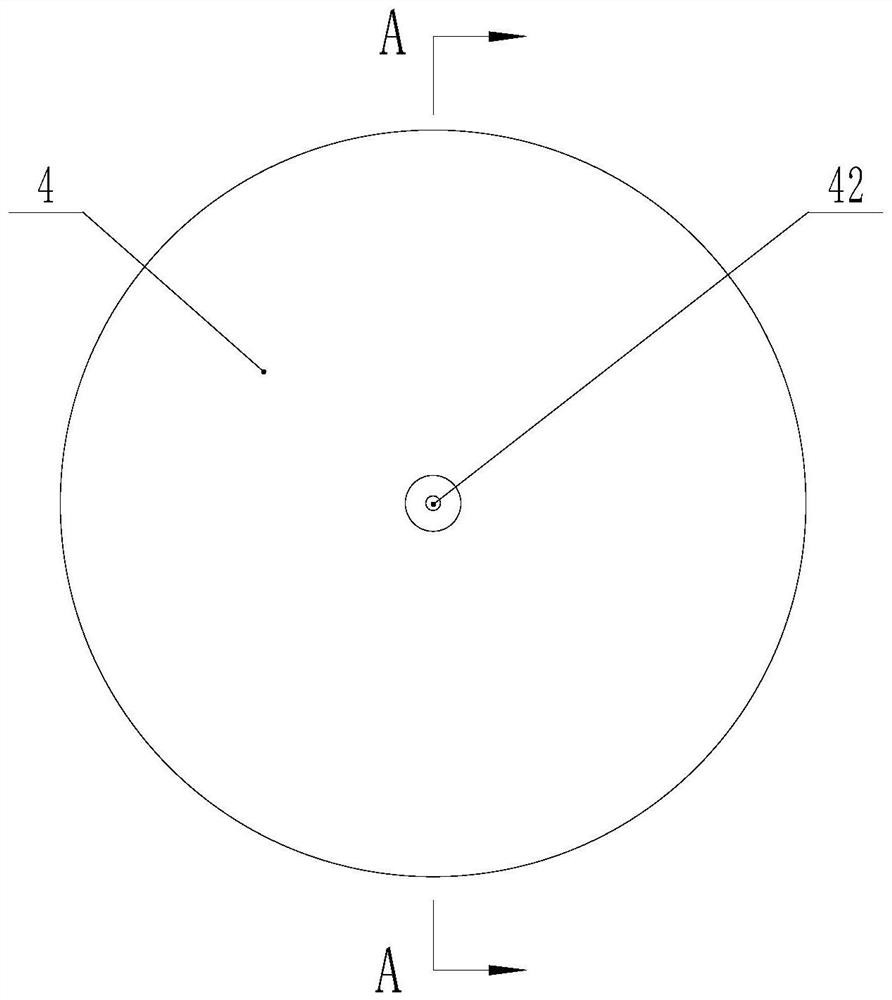

[0028] Such as Figure 3-4 As shown, a diamond ring line fabrication apparatus is provided, and six bracketing holes 41, outlet port 43, and slip ring 44, and six divided hole 41 are mounted in the rotten adjustment assembly. On one side of the 4, the slip ring 44 is provided with an inward port 42, and the slip ring 44 is rotatably mounted in the middle of the ignition adjustment assembly 4 through the pulley 45.

[0029] Such as Figure 5-6 As shown, the winding mechanism includes a wind turntable 8, six steel wire fixing screws 9 and six surround steel wires 6, and six steel wire fixing screws 9 are mounted on the winding turntable 8, winding turntable 8 The intermediate is provided with a cross hole 24, and one end of the wire 6 is mounted on the steel wire fixing screw 9, and the other end is mounted on the 捻 adjustment assembly 4 after the wire hole 41.

[0030] The tensioning mechanism includes a disparrier wheel 21, a second guide wheel assembly 16, a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com