Large-width cast-in-place box girder and construction method thereof

A technology of box girder construction and large width, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems that cannot meet the needs of box girder construction progress and construction cost, complex formwork support and disassembly, and large engineering quantity. Achieve the effect of shortening the construction period, simplifying the construction process and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Such as Figure 9 As shown, the large-width cast-in-place box girder construction method includes the following steps:

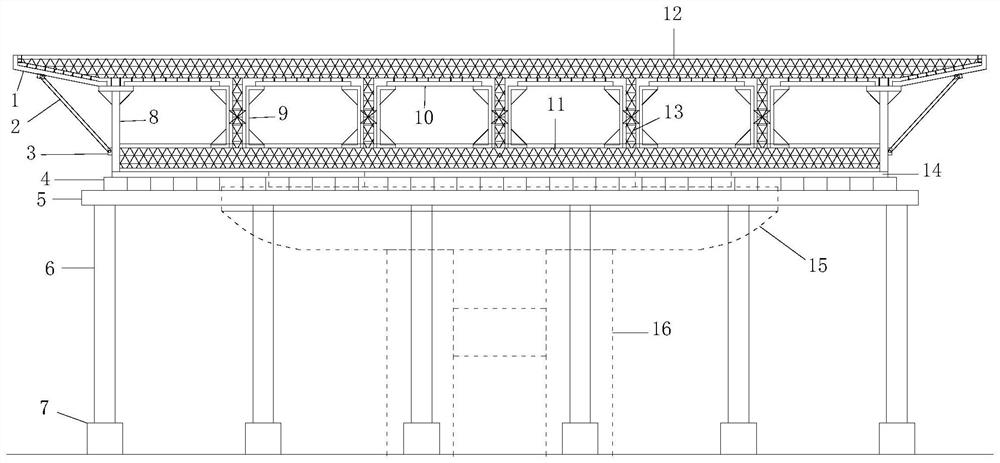

[0041] S000, please refer to figure 1 First, leveling, rolling, etc. are carried out within the scope of the construction site where the support 6 needs to be erected, and then the poured reinforced concrete strip foundation is used as the support foundation 7, and the support foundation 7 is poured on the design position of the construction site. The steel pipe support 6 is bolted on the pre-embedded steel plate, and the crossbeam 5 is bolted on the top of the support 6, and finally the distribution beam 4 is arranged and installed on the crossbeam 5;

[0042] in Figure 9 A simplified flowchart is shown in .

[0043] S100, laying and installing the bottom form 14 on the distribution beam 4, and pre-pressing all the supports 6, and then adjusting the elevation of the bottom form 14 to meet the design requirements;

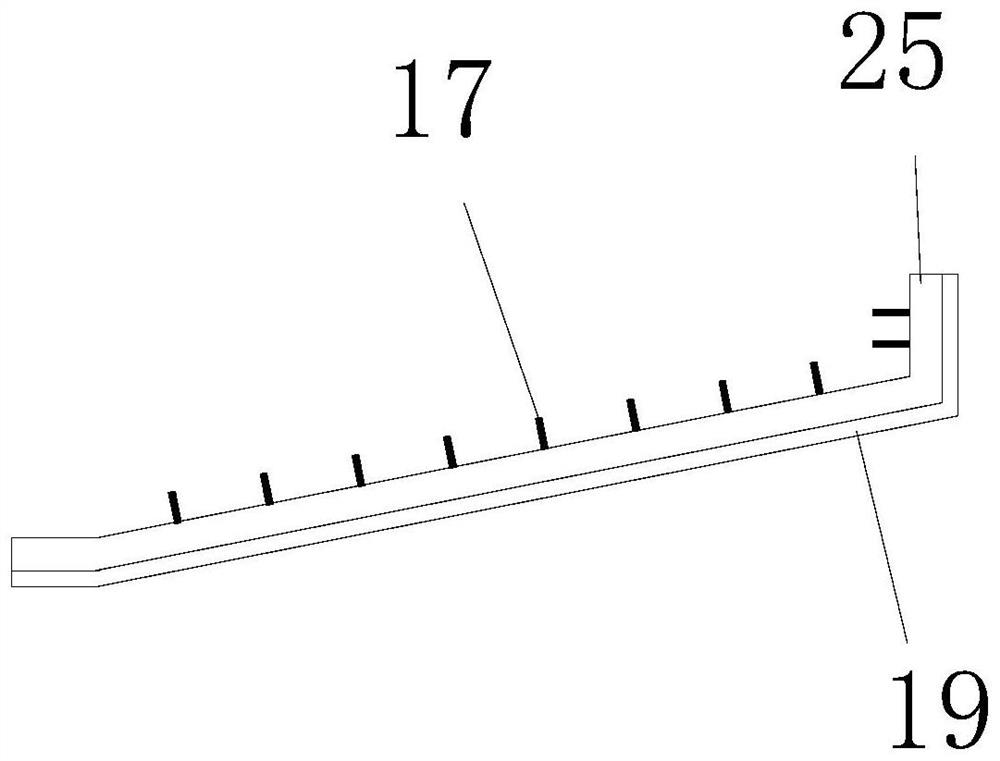

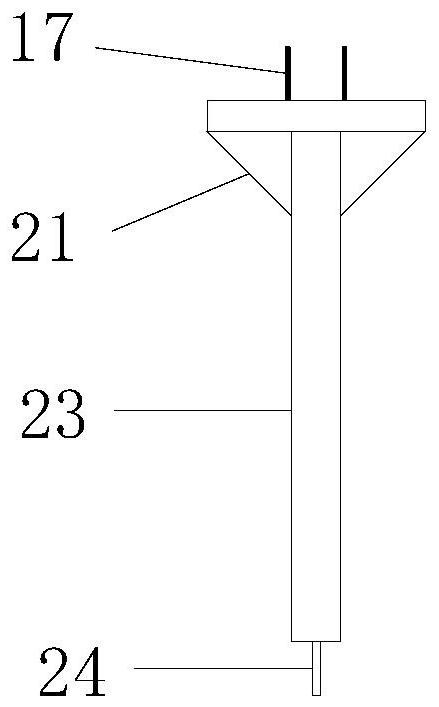

[0044] S200, installing the ri...

Embodiment 2

[0056] see Figure 8 , the large-width cast-in-place box girder is constructed by the above-mentioned large-width cast-in-place box girder construction method. The large-width cast-in-place box girder manufactured by the construction method of the present application has the advantages of short construction period, higher strength and simple process. figure 1 The cap beam 15 and buttress 16 in the bridge are a part of the bridge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com