Support method of swing type anti-seismic recoverable anchor rod suitable for complex slope support

An anchor rod and slope technology, applied in excavation, climate change adaptation, construction, etc., can solve the problems of slope rock and soil collapse, failure of anchoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

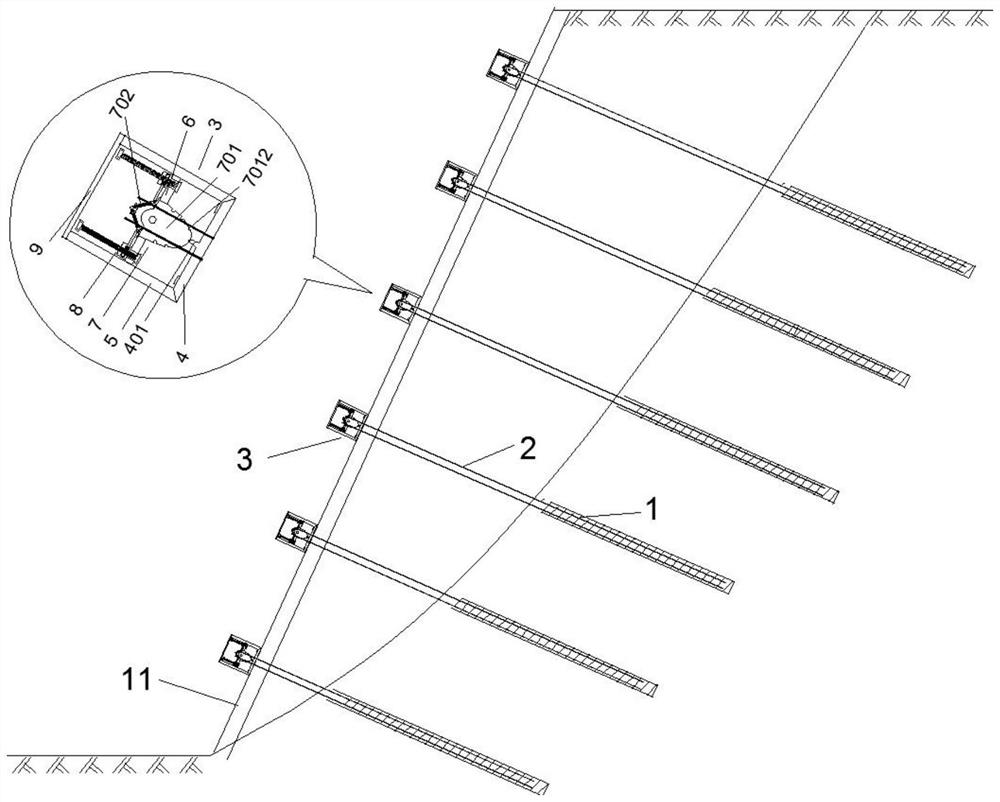

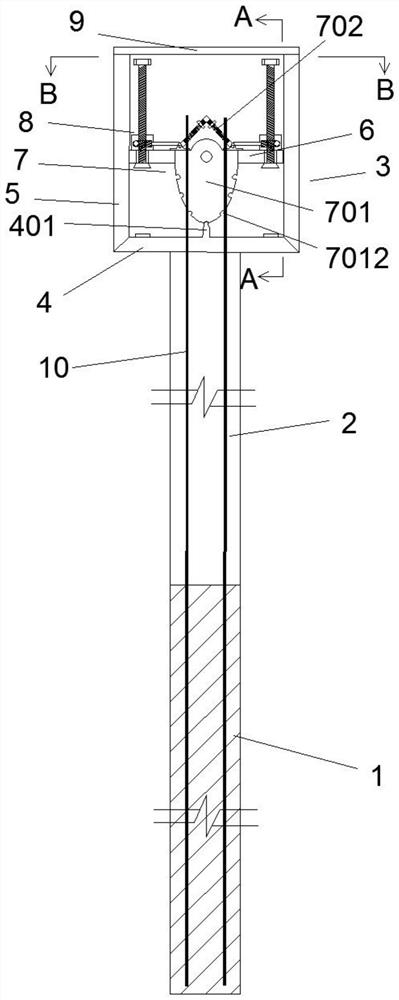

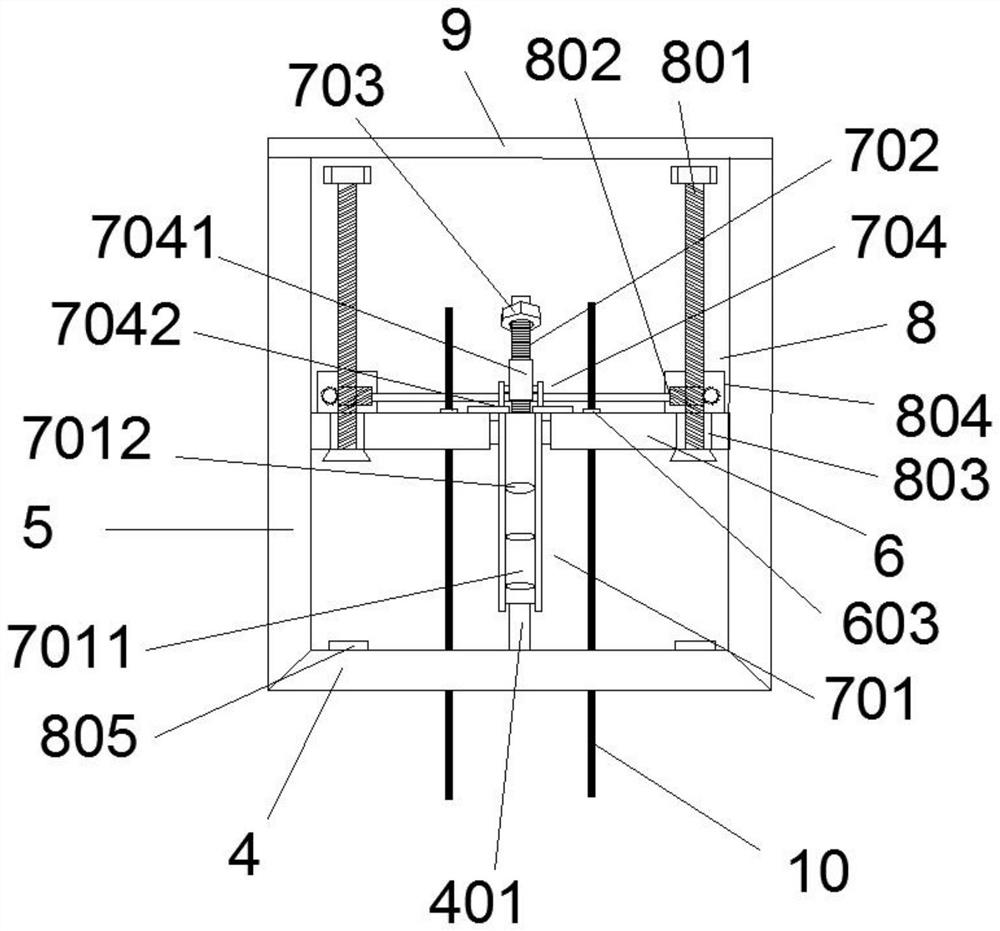

[0042] Such as figure 1 , 2, 3, 4, 5, 6, and 7, a support method for a rocking-type aseismic-recoverable bolt applicable to complex slope support, the rocking-type aseismic-restorable bolt includes anchoring section 1, free Segment 2 and Anchor Head 3. The anchor head 3 includes a backing plate 4, a rigid sliding wall 5, an anchor 6, an anti-seismic device 7, an anchor lifting device 8 and a cover plate 9, and the center of the backing plate 4 is provided with a raised stopper 401, The anchor 6 is nested in the rigid sliding wall 5 and is slidably connected with the rigid sliding wall 5. The middle part of the anchor 6 is provided with a strip-shaped through hole 601, and the anchor 6 is located above the central part of the strip-shaped through hole 601. Middle indicator 602 is indicated.

[0043] The anchorage 6 is provided with several uniform and symmetrically distributed circular through-holes. The number, diameter and distribution of the circular through-holes should ...

Embodiment 2

[0060] After the rocking earthquake-resistant recoverable bolt in Example 1 is damaged by an earthquake, the following steps should be followed for recovery:

[0061] Step 1: Anchor sealing and unsealing, when the anchor is unsealed, the anchor head 3 is protected from damage;

[0062] Step 2: reset the anti-seismic device 7;

[0063] Step 3: Second anchor sealing.

[0064] In the second step, the lifting screw 801 is rotated to the bottom, and the lifting screw 801 is continued to be rotated, the anchorage 6 is held up, the anti-seismic device 7 is in a suspended state, and the nuts a703 on both sides of the upper screw structure 702 are rotated to the screw At the bottom end, lock the anti-seismic device 7 at the balance position, reset the anti-seismic device 7, and then rotate the lifting screw 801 to the top. During the rising process of the lifting screw 801, the stopper 401 and the lower semi-elliptical cutter head 701 are at the highest position. The limiting slots 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com