Advanced stress release construction method for severe large deformation tunnel

A technology of stress release and construction method, applied in tunnels, tunnel linings, earthwork drilling and other directions, can solve the problems of large force, large deformation of the tunnel, large burial depth, etc., to achieve easy control, ensure stability, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described now in conjunction with accompanying drawing.

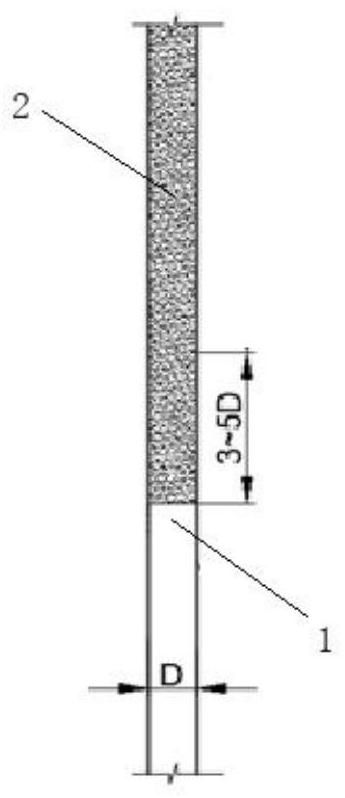

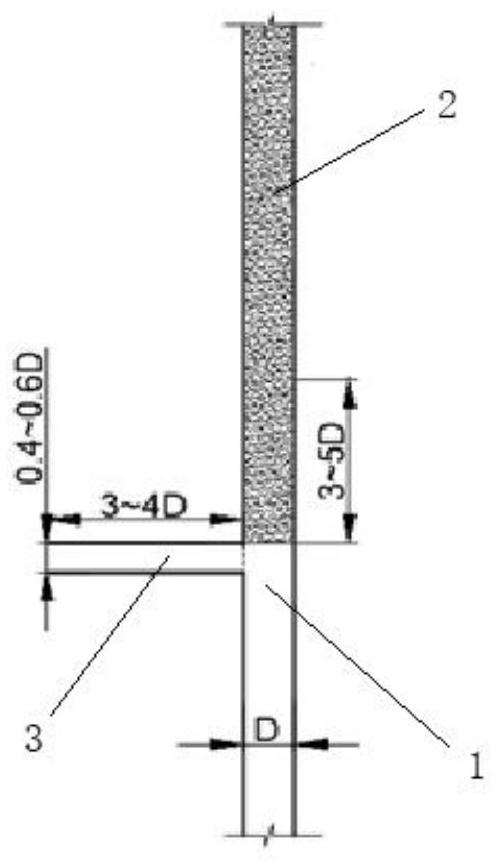

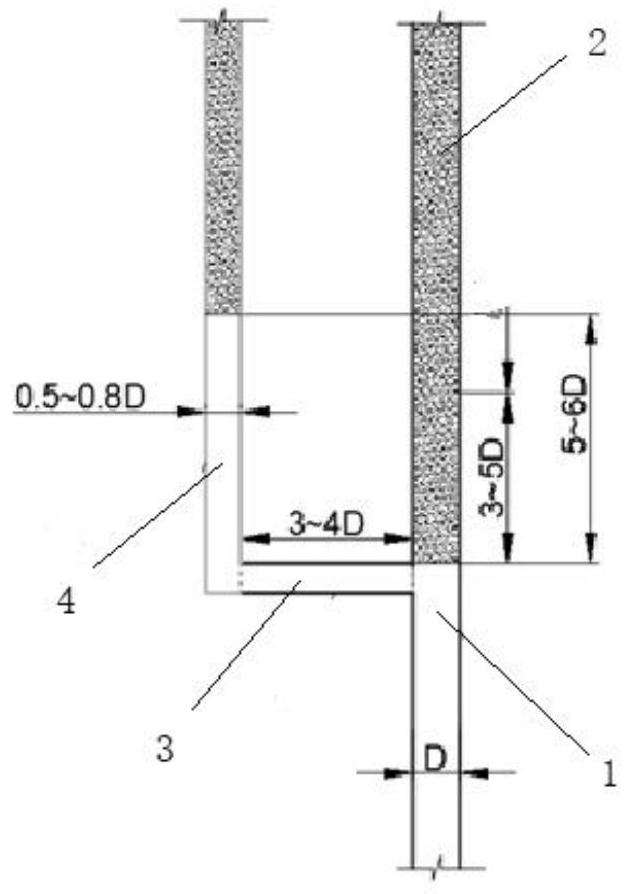

[0034] see Figure 1-4 , the present invention provides a construction method for advanced stress release of severe large deformation tunnel, comprising the following steps:

[0035] S1: The distance from the excavation of the main tunnel 1 to the severe deformation section 2 of the tunnel is a multiple of the diameter of the main tunnel, and the construction is stopped, and D is the diameter of the main tunnel;

[0036] S2: Excavate a connecting cross passage 3 perpendicular to the main tunnel on one side of the excavation surface of the main tunnel. The excavation length is 3-4D, and the hole diameter is 0.4-0.6D. If it is too long, it cannot play the role of stress release, if it is too short, it will affect the stability of the positive hole;

[0037] S3: Excavate the advanced parallel pilot tunnel at the end of the connecting cross passage 3, the advanced parallel pilo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com