Wellhead foam drainage gas production foam automatic detection device

An automatic detection device and automatic detection technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of scientific management of defoaming dose, automatic detection of unfavorable gas fields, accuracy, and real-time gaps, etc., to achieve Optimizing structural design, reducing error factors, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention is further described:

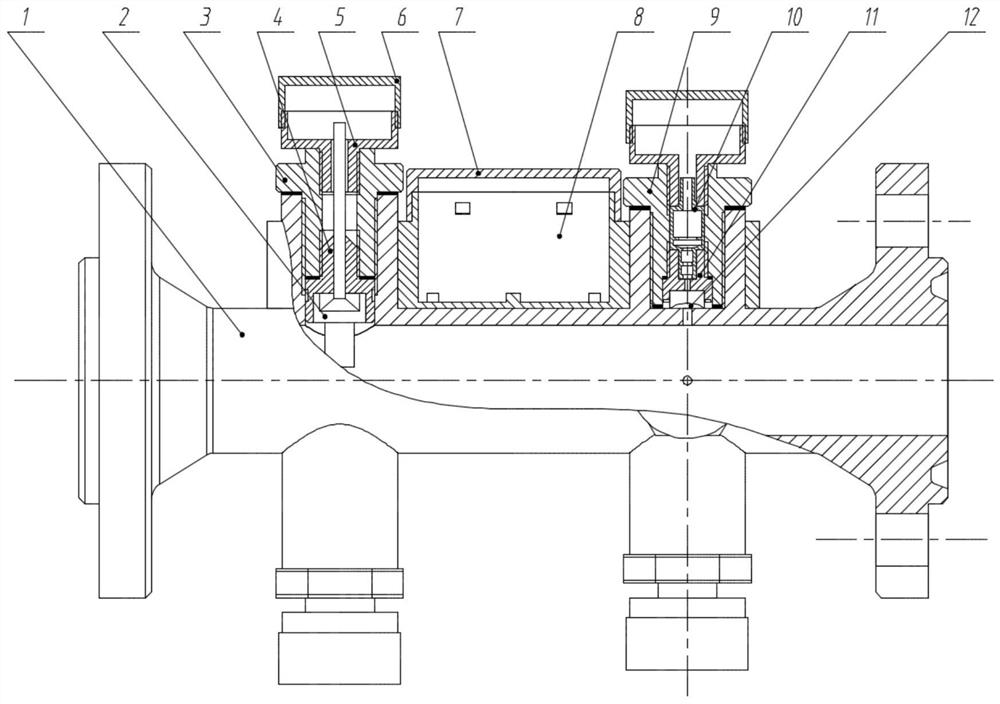

[0032] see figure 1 , the mechanical structure part includes a sealing lens 12, an infrared mounting head 11, an optical cavity 10, an infrared sensor housing 9, an upper housing 7 of a processing system, a lower housing 8 of a processing system, an upper housing 6 of a detection front end, a lower housing 5 of a detection front end, and a capacitive sensor housing 3. Detection capacitor 2, capacitor installation head 4, device shell 1. The capacitive sensor housing 3 is connected to the device housing 1 through external threads, the capacitive mounting head 4 is connected to the internal thread of the capacitive sensor housing 3 through threads, the detection front lower housing 5 is connected to the capacitive sensor housing 3 through threads, and the detection front upper housing 6 is threaded It is connected to the lower shell 5 of the detection front end, and the detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com