Hazardous chemical production enterprise risk assessment method, system and device and medium

A risk assessment system and risk assessment technology, applied in the field of risk assessment of hazardous chemical production enterprises, can solve the problems of few enterprise accident data samples, few results, and the assessment results are not stable enough, so as to improve reliability and improve calculation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

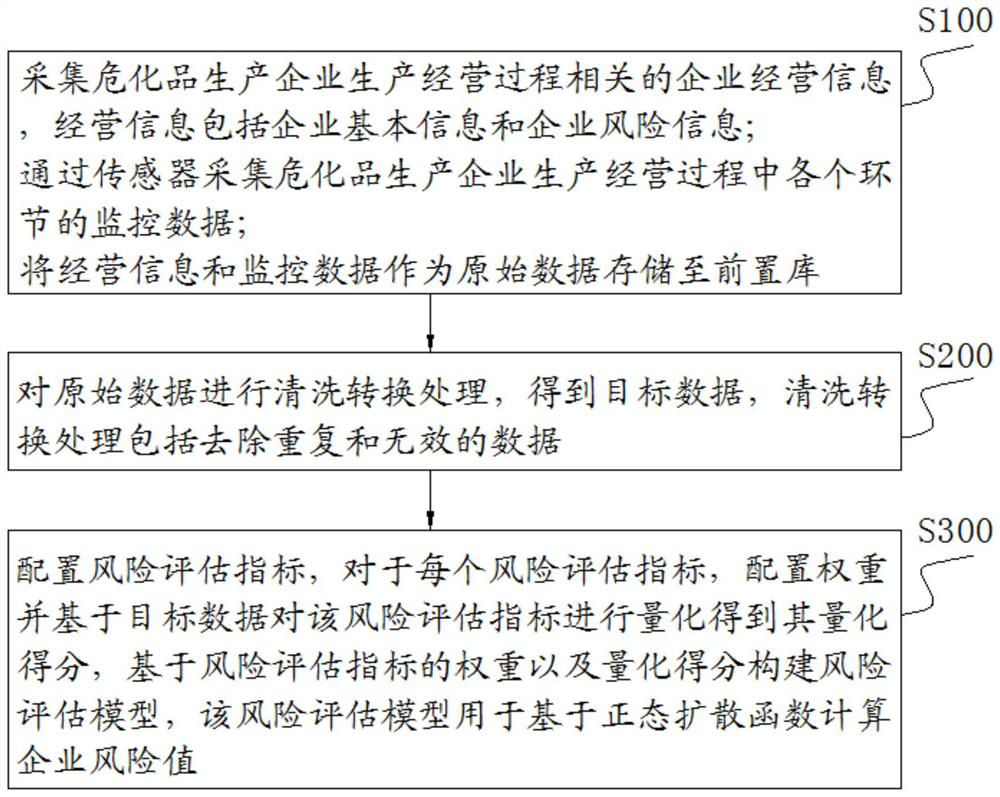

[0057] The risk assessment method for a hazardous chemical production enterprise of the present invention comprises the following steps:

[0058] S100. Collect business operation information related to the production and operation process of the hazardous chemical production enterprise, where the business information includes basic enterprise information and enterprise risk information;

[0059] Collect monitoring data of various links in the production and operation process of hazardous chemical production enterprises through sensors;

[0060] Store business information and monitoring data as raw data in the front-end database;

[0061] S300. Perform cleaning and conversion processing on the original data to obtain target data, and the cleaning and conversion processing includes removing duplicate and invalid data;

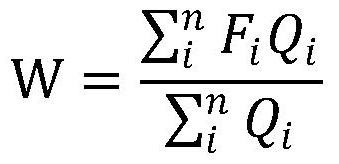

[0062] S400. Configure risk assessment indicators. For each risk assessment indicator, configure the weight and quantify the risk assessment indicator based on ...

Embodiment 2

[0110] The risk assessment system for hazardous chemical production enterprises of the present invention includes a safety production data entry module, a device sensor acquisition module, a data cleaning and conversion processing module, a risk assessment index calculation module, a pre-store and a standard library, and the safety production data entry module is used for Collect business information related to the production and operation process of hazardous chemical production enterprises, including business basic information and corporate risk information;

[0111] The sensor acquisition module of the device is used to collect monitoring data of various links in the production and operation process of hazardous chemical production enterprises through sensors; the data cleaning and conversion processing module is used to perform cleaning and conversion processing on the original data to obtain target data. The cleaning and conversion processing includes removing Duplicate an...

Embodiment 3

[0157] The device of the present invention includes: at least one memory and at least one processor; the at least one memory is used to store a machine-readable program; the at least one processor is used to call the machine-readable program to execute the embodiment 1 public method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com