Assembly line detection equipment for carrying out quality detection through CCD (Charge Coupled Device) image acquisition

A technology for image acquisition and detection equipment, which is applied to structural parts of electrical equipment, cooling/ventilation/heating transformation, rack/frame structure, etc. , avoid dust accumulation, accelerate the effect of heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

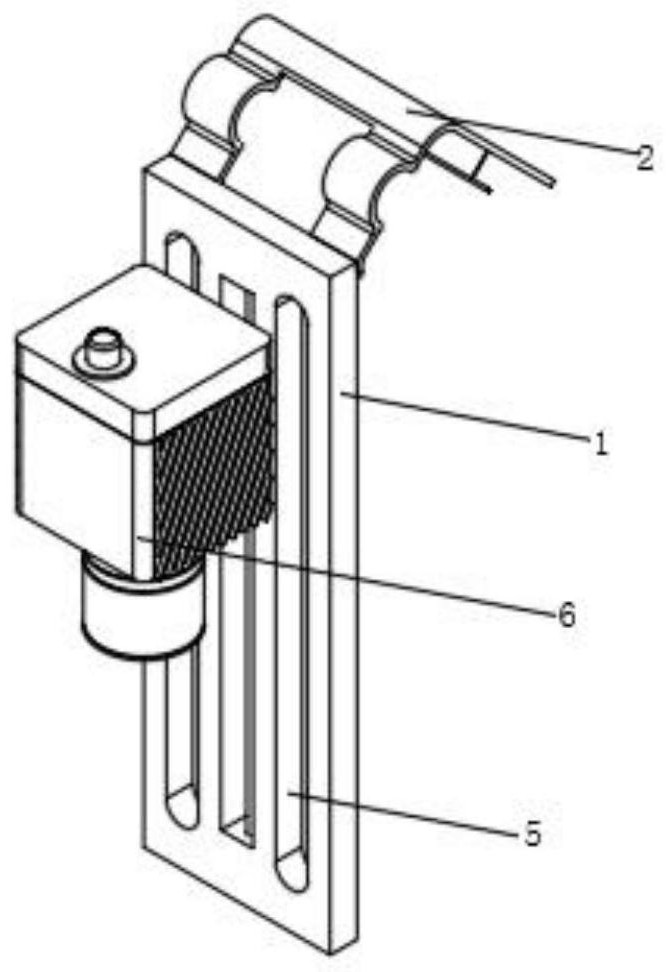

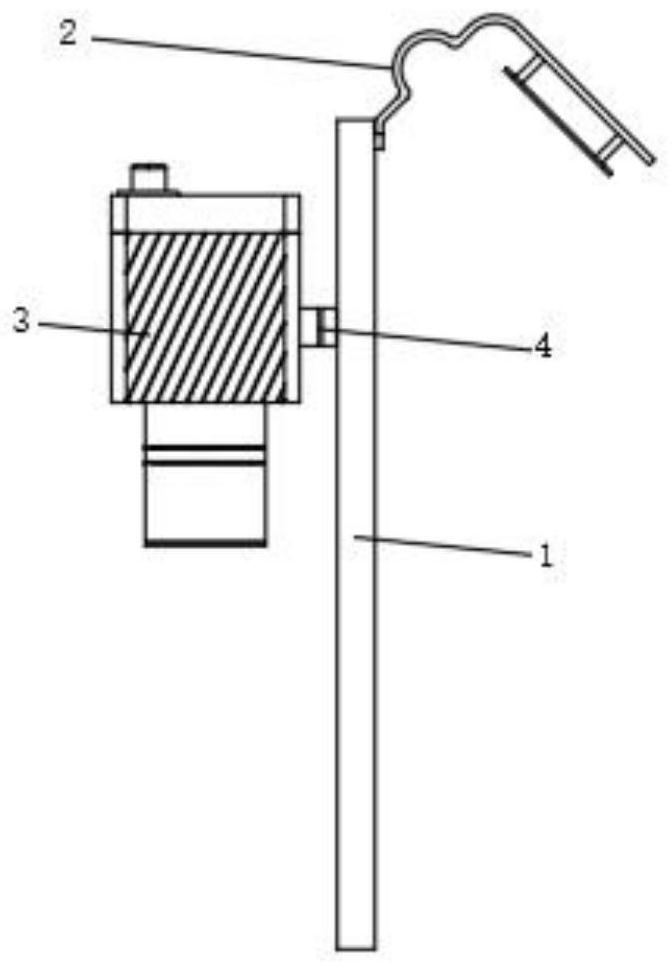

[0033] Such as figure 1 , 2 , 3, 4, and 6, a pipeline inspection device for quality inspection through CCD image acquisition, including a support frame 1 of the driving device, a sliding connector 4, a rectangular through groove 5 and a CCD image acquisition device 6, the driving device The end face of the support frame 1 is provided with three rectangular through grooves 5, and a slide bar is arranged in the middle rectangular through groove 5 of the support frame 1 of the driving device. The shaft of the slide bar is provided with a sliding connector 4, the other end of which is A CCD image acquisition device 6 is provided;

[0034] The upper end of the support frame 1 of the driving device is provided with an angle-adjustable blowing device 2, and the angle-adjusting blowing device 2 is aligned with the CCD image acquisition device 6 to blow air, and the two sides of the CCD image acquisition device 6 are provided with heat dissipation mechanisms for the image acquisition ...

Embodiment 2

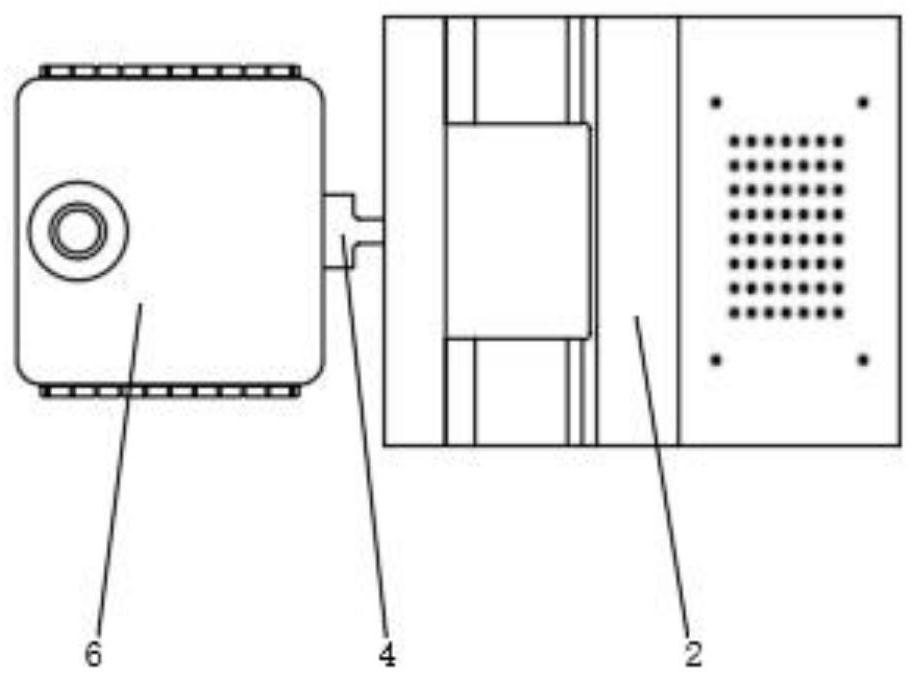

[0038] Such as figure 1 , 4 , 5, and 6, wherein the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference is that the heat dissipation mechanism 3 of the image acquisition device includes a heat dissipation plate 301, a heat-conducting circular disc 302 and an inclined heat dissipation fin 303, and the two sides of the CCD image acquisition device 6 are provided with a heat dissipation plate 301, and the heat dissipation plate 301 is facing The end face of the CCD image acquisition device 6 is provided with a heat-conducting circular disk 302, and the other end of the heat dissipation plate 301 is provided with an inclined heat dissipation fin 303;

[0039] The heat dissipation plate 301 and the inclined heat dissipation fins 303 are integrally arranged, the heat dissipation plate 301 is fixedly connected w...

Embodiment 3

[0041] Such as Figure 5 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference is that a plug is provided between the heat dissipation plate 301 and the heat conduction circular disk 302 , and the heat dissipation plate 301 and the heat conduction circular disk 302 are connected with the CCD image acquisition device 6 through the bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com