Four-wheel drive mini-tiller

A micro-tiller and frame technology, which is applied in the fields of tillage machines, agricultural machinery and implements, etc., can solve the problems of low production efficiency, many types of micro-tillers, and high equipment costs, and achieve compact structure, promote lightweight and The effect of miniaturization and compact space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

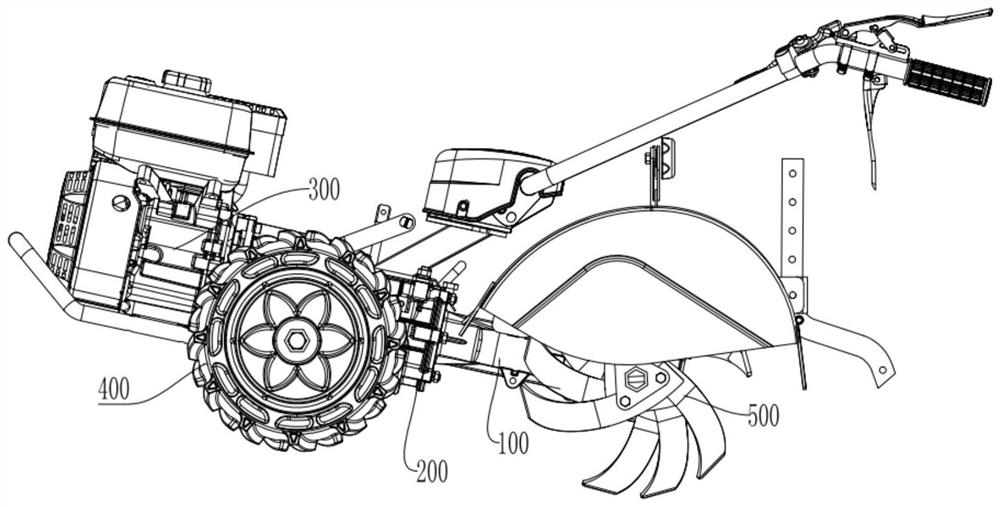

[0043] The embodiment is basically as attached Figure 1 to Figure 10 shown, combined with Figure 1 to Figure 4 , a four-wheel drive tiller, comprising a frame 100, a driver 300, a transmission 200, a traveling wheel 400 and a tool 500, the driver 300 and the transmission 200 are fixedly installed on the frame 100, and the driver 300 is used to provide power for the transmission 200. This implementation In an example, the driver 300 may use a motor.

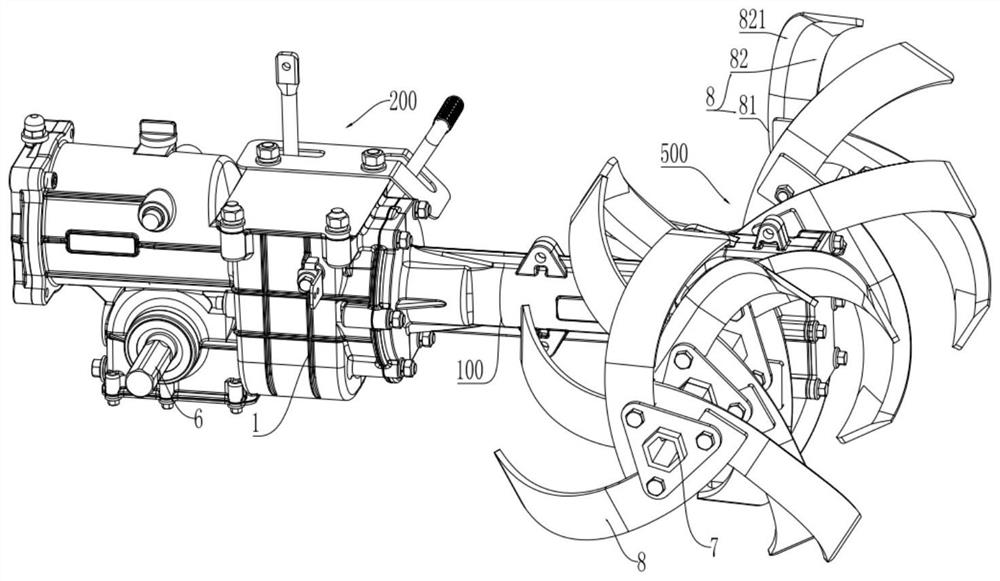

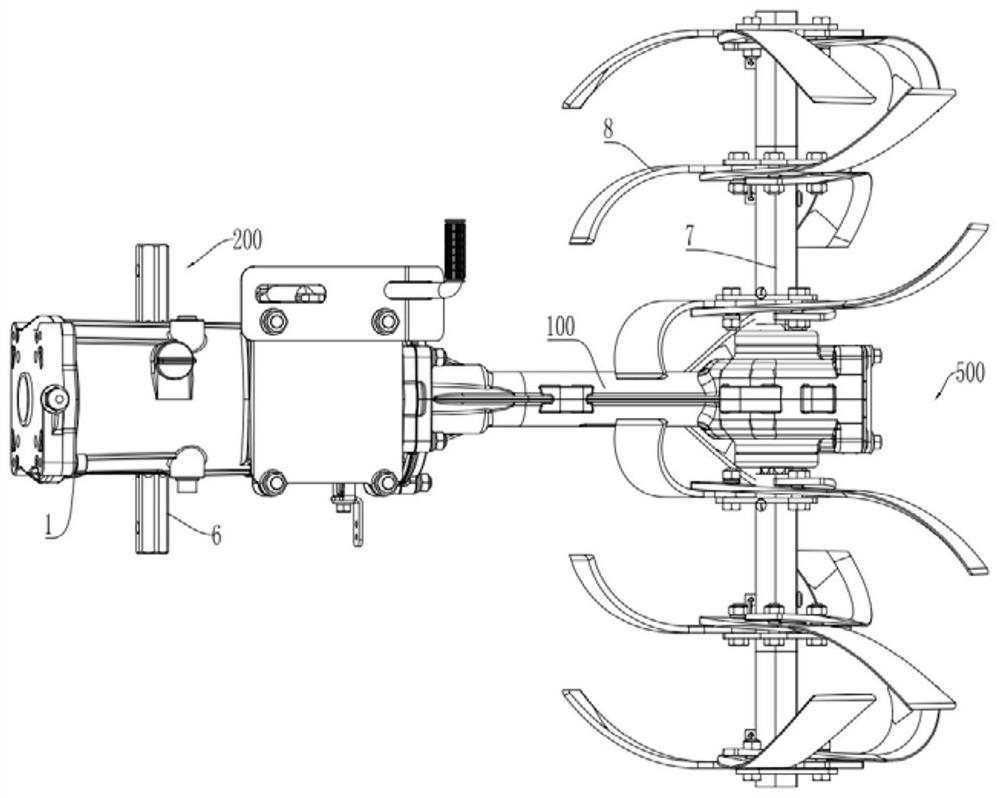

[0044] combine Figure 5 to Figure 8 The transmission 200 includes a case body 10 and a main shaft 1, a travel output shaft 2, a tool output shaft 3, an intermediate shaft 4 and a reverse gear shaft 5 that are rotatably connected to the case body 10, and a clutch 600 is connected between the driver 300 and the main shaft 1, The travel output shaft 2 drives the travel wheel 400 to rotate, and the tool output shaft 3 drives the tool 500 to rotate; the box body 10 is integrally formed with two interconnected clutch chambers 20 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com