Straw returning device

A straw and crushing device technology, which is applied to shovels, plows, agricultural machinery and implements, etc., can solve the problems of low crushing efficiency, straw crushing degree, and limited mixing uniformity of crushed straw and soil, so as to improve the mixing efficiency and degree of mixing , Uniform fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

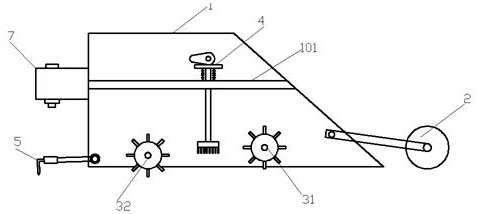

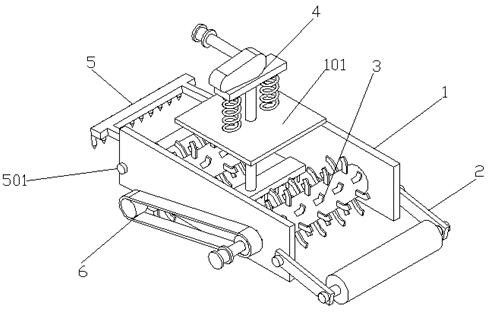

[0038] A straw returning device, including a shell 1, the shape of the shell 1 is not limited, it can be customized according to actual needs, the shell 1 is provided with a crushing device 3, the purpose of the crushing device 3 is to achieve crushing The function is mainly to crush the straw, mix the crushed straw with the soil evenly, and avoid that most of the crushed straw is still exposed on the soil surface and is easily blown away by the wind. Not only cannot the purpose of returning the straw to the field, but also will cause environmental pollution;

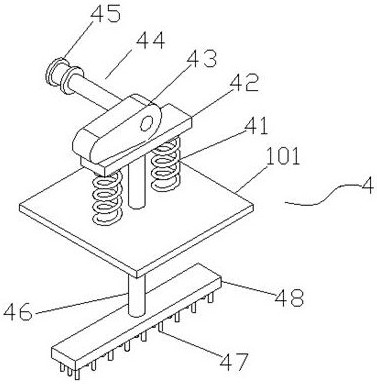

[0039] The middle position of the pulverizing device 3 is provided with an automatic pressing device 4. The purpose of the automatic pressing device 4 provided by the present invention is to insert and press the crushed straw into the depth of the soil, so that it can be mixed evenly with the soil, thereby improving the fertilizer efficiency of the soil. can be more uniform;

[0040] The outer right side of the housing...

Embodiment 2

[0054] On the basis of Embodiment 1, a carding device 5 is provided on the left side of the housing 1, and the connecting ring 52 of the carding device 5 is sleeved on the connecting rod 501, and the connecting rod 501 is arranged at the left end of the housing 1 , the carding device 5 includes a connecting frame 53, and the right end of the connecting frame 53 is provided with a connecting ring 52;

[0055] The left end of the connecting frame 53 is lowered evenly to be provided with a plurality of rake teeth 51, which are arranged side by side at a certain interval to facilitate the raking operation of the soil; after the crushed straw is mixed with the soil, the surface will Uneven, some places are too high, some places are too low, need to go through manual leveling treatment, increase the manpower burden, therefore, the present invention can pass through the cooperation of the connecting frame 53 and the rake teeth 51 by setting the carding device 5 The crushed soil is ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com