Pipe raw material mixing system

A technology for mixing materials and raw materials, applied in the field of pipe material mixing system, can solve the problems of low mixing efficiency, inability to pre-mix multiple auxiliary materials, and uneven mixing of auxiliary materials, and achieve the effect of eliminating poor work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

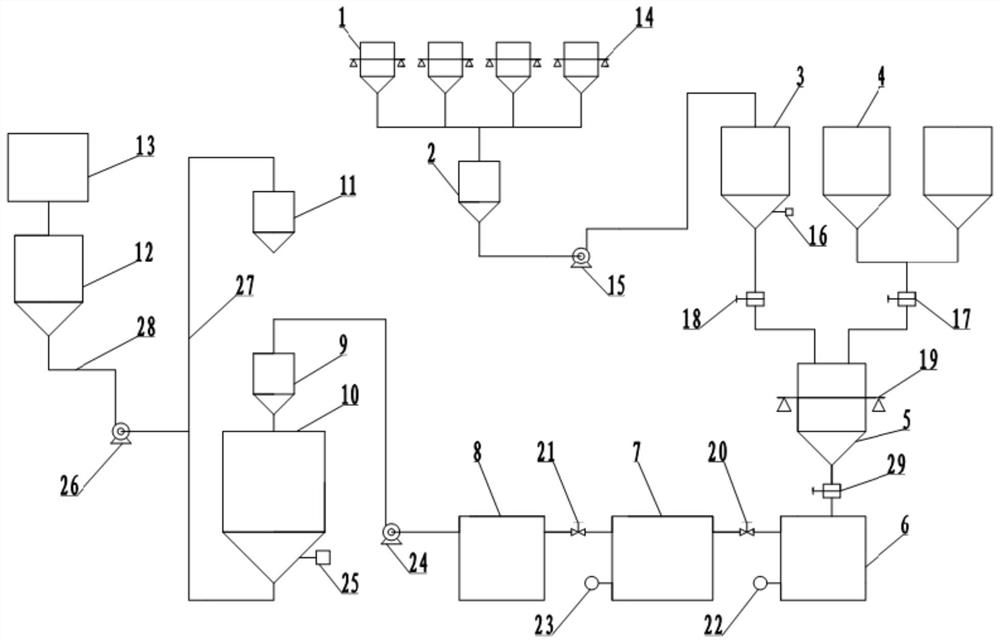

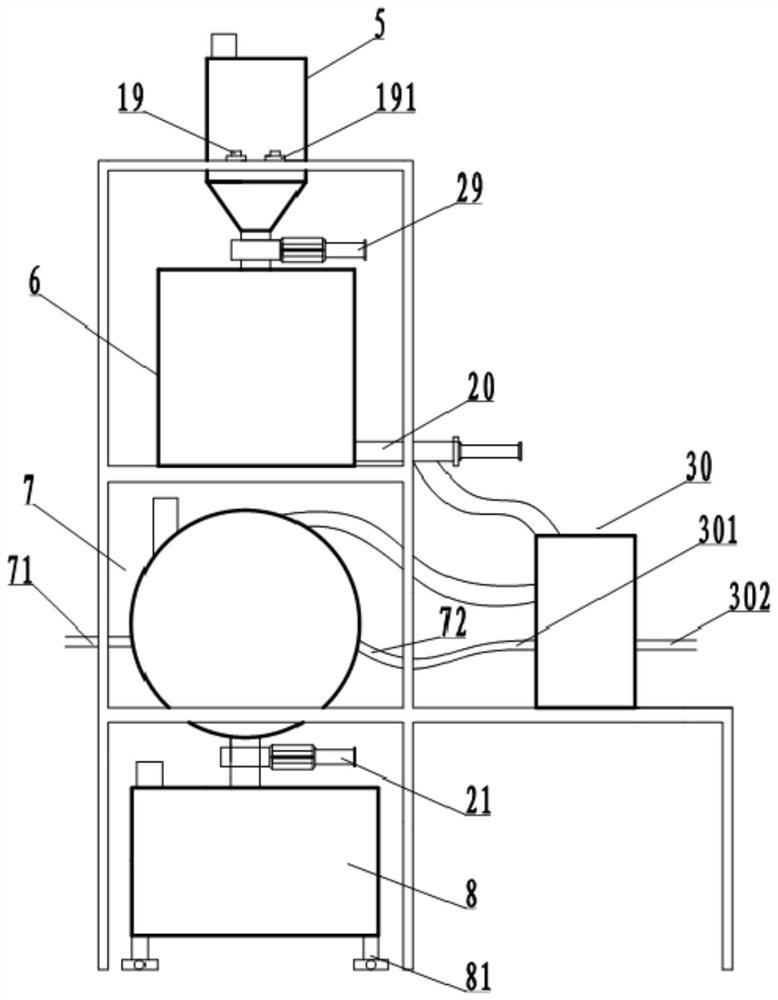

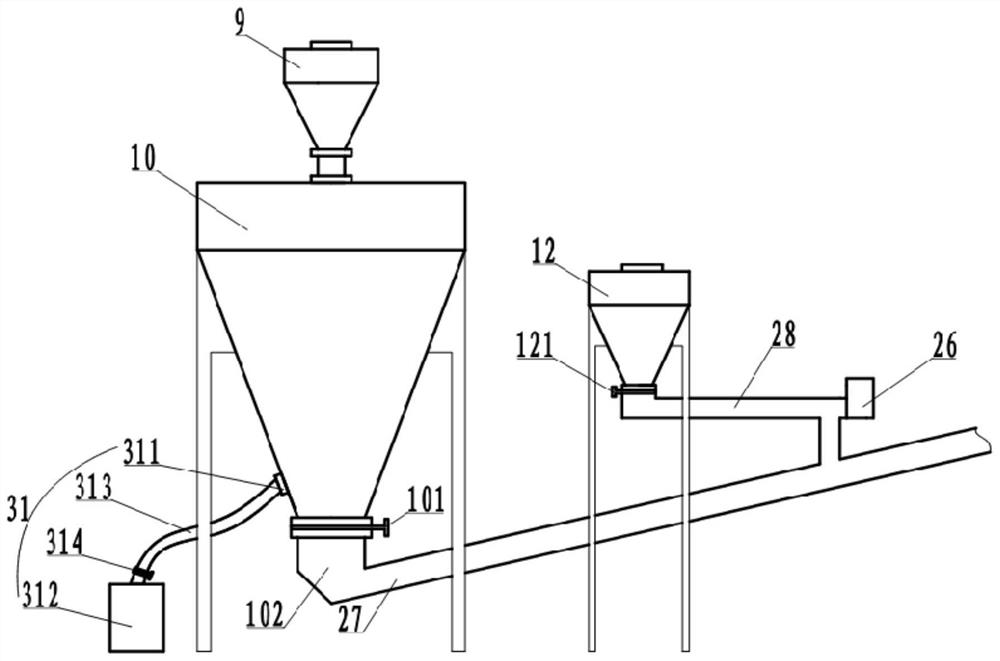

[0037] The following is further described in detail through specific implementation methods:

[0038] The reference signs in the drawings of the description include: auxiliary material bin 1, mixer 2, auxiliary material tank 3, main material tank 4, weighing bucket 5, heat mixer 6, cold mixer 7, cold mix inlet pipe 71, cold mix outlet Water pipe 72, temporary storage tank 8, support feet 81, buffer tank 9, raw material tank 10, first gate 101, discharge hopper 102, screw shaft 103, feeding tank 11, waste tank 12, second gate 121, crusher 13 , automatic weighing scale 14, first vacuum pump 15, first level transmitter 16, first control valve 17, second control valve 18, weight sensor 19, pressure arm 191, hot mix discharge valve 20, cold mix discharge Material valve 21, first temperature sensor 22, second temperature sensor 23, second vacuum pump 24, second level transmitter 25, third vacuum pump 26, discharge pipe 27, feed pipe 28, third control valve 29, Precooler 30, precool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com