Sponge foam soft light synthetic fatting agent as well as preparation method and application thereof

A fatliquoring and softening technology, which is applied in the field of leather making to improve physical and mechanical properties, lightness and softness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

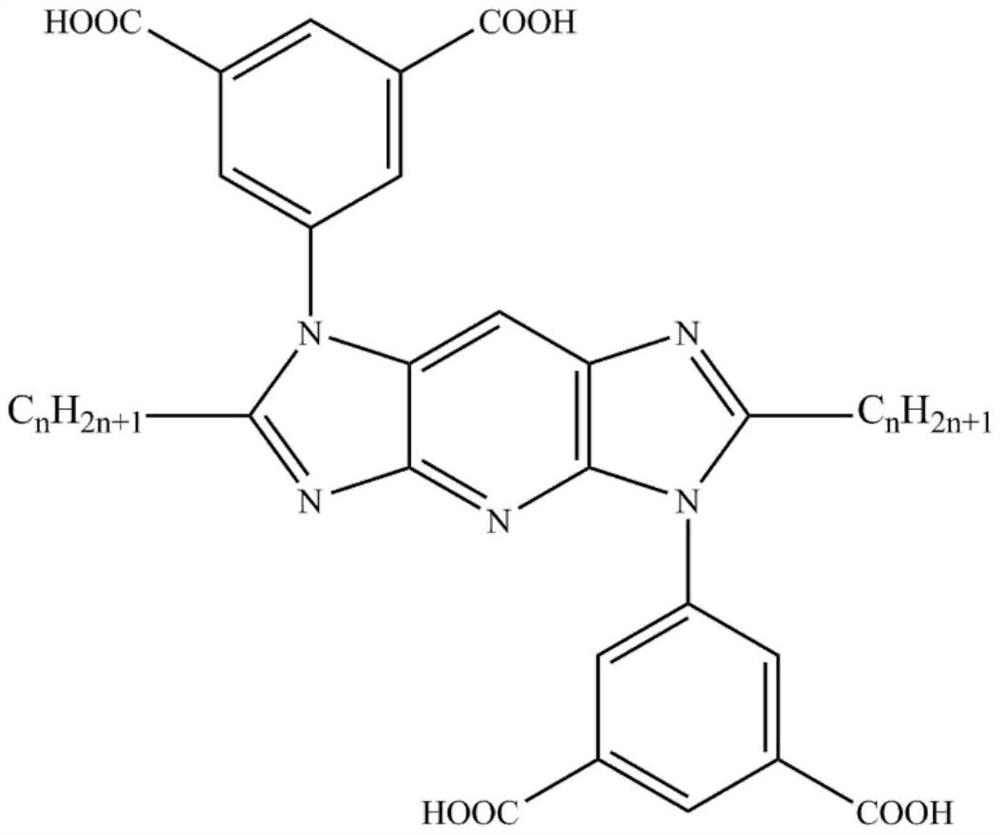

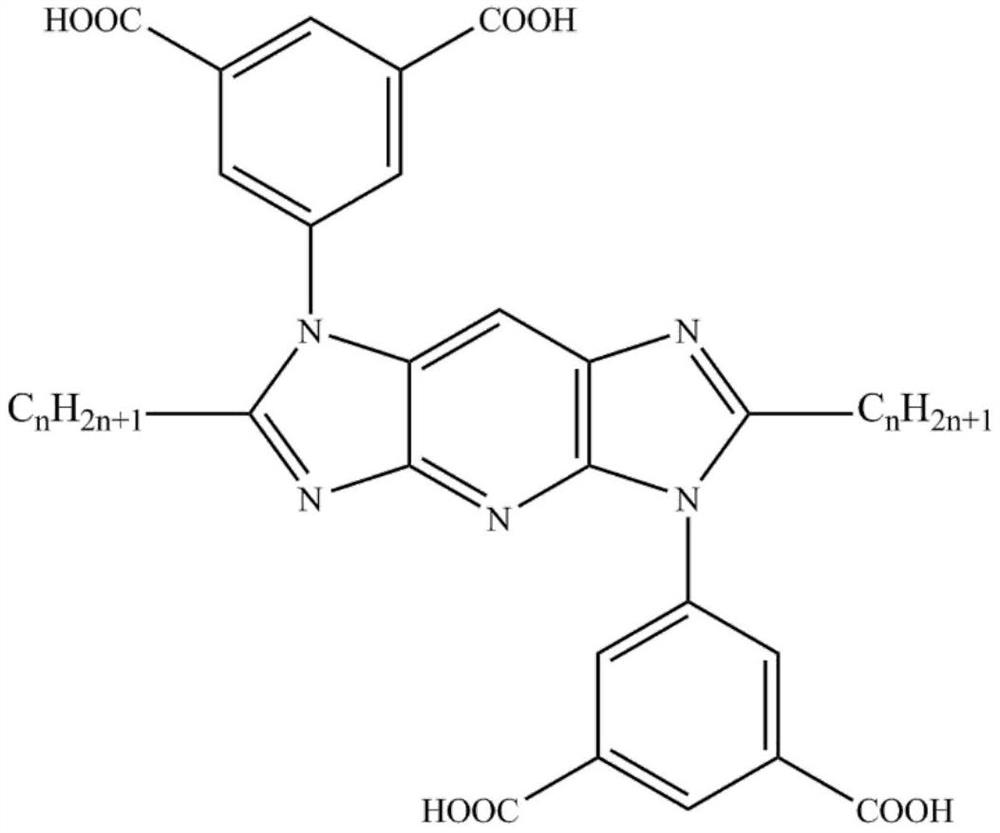

Image

Examples

Example Embodiment

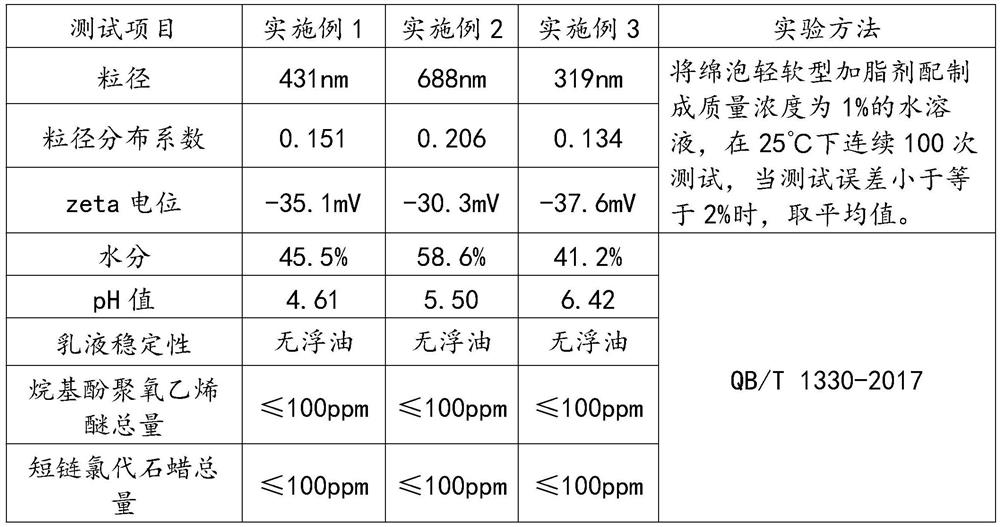

[0027] Example 1:

[0028] Method for preparing a sputum soft and light synthetic fat-lipid, including the following steps:

[0029] 1 5 parts of polyphosphoric acid, 87 phosphoric acid, 5 parts of phosphorus, 3 parts of trichlorophous phosphorus mix well, under the protection of nitrogen, the temperature at 50 ° C, stirred for 6 h, resulting in a catalyst solution;

[0030] 2 Take 8 parts of the catalyst solution, dissolved in 100 parts of 2,3,5,6-tetraminopyridine hydrochloride, under the protection of nitrogen, adjusted 80 ° C, reaction for 6 h, and then add 210 parts of tapic acid, heating to 150 ° C reaction for 1 h, slowly cooling and cooled, resulting in an intermediate;

[0031] 3 Take 1000 intermediates, 1500 parts of 1,4-dioxane, 5 parts of palladium, 2 parts of carbonate, mixed at 50 ° C, and then add 2100 parts of 5-bromobenyl terephthalic acid, reaction 6h, The post-rotation evaporation removes 1,4-dioxane, and finally adjusts the temperature to 30 ° C, adding 3,500 p...

Example Embodiment

[0032] Example 2

[0033] Method for preparing a sputum soft and light synthetic fat-lipid, including the following steps:

[0034] 1 Wen 10 parts of polyphosphate, 82 phosphoric acid, 3 parts of phosphorus, 3 parts of trichlorophous phosphorus mix well, under the protection of nitrogen, the temperature is 40 ° C, stirred for 6 h, resulting in a catalyst solution;

[0035] 2 Take 5 parts of the catalyst solution, dissolve in 95 parts of sulfate, under the protection of nitrogen, and the reaction is adjusted for 6 h, and then 195 parts of stearic acid, the temperature is increased to 180 ° C for 0.5 h, slowly cooling and cooling, resulting in an intermediate ;

[0036] 3 Take 950 intermediates, 1800 parts of 1,4-dioxane, 8 parts of palladium, 3 parts of carbonate, mixed at 80 ° C, and then add 1800 parts of 5-bromobenenenenenpaic acid, reaction 4h, The post-rotation evaporation removes 1,4-dioxane, and finally adjusts the temperature to 50 ° C, adding 3,000 parts of water, high-speed...

Example Embodiment

[0037] Example 3

[0038] Method for preparing a sputum soft and light synthetic fat-lipid, including the following steps:

[0039] 1 5 parts of polyphosphoric acid, 100 parts of phosphoric acid, 3 parts of phosphorus, 2 parts of trichlorophous phosphorus, under the protection of nitrogen, the adjustment temperature at 35 ° C, stirred for 8 h, to obtain a catalyst solution;

[0040] 2 Take 10 parts of the catalyst solution, dissolved in 85 parts of 2, 3, 5, 6-tetraminopyridine hydrochloride, under the protection of nitrogen, adjusted 100 ° C, reaction 8h, and then add 220 parts of tapic acid, heating to 165 The reaction was reacted for 1 h, slowly cooling and cooled to obtain an intermediate;

[0041] 3 Take 800 parts of the intermediate, 2000 parts 1,4-dioxane, 3 parts of palladium, 9 parts of carbonate, mixed at 95 ° C, and then 1,950 parts of 5-bromobenyl terephthalic acid, reaction 12h, The post-rotation evaporation removes 1,4-dioxane, and finally adjusts the temperature to 4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap