Precision forming aluminum alloy material suitable for high-toughness structural part of new energy automobile and preparation method of precision forming aluminum alloy material

A technology for new energy vehicles and aluminum alloy materials, applied in the field of aluminum alloys, can solve the problems of poor casting performance, difficult die-casting, low strength, etc., to improve mechanical properties and corrosion resistance, improve tensile strength, and refine grains. grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

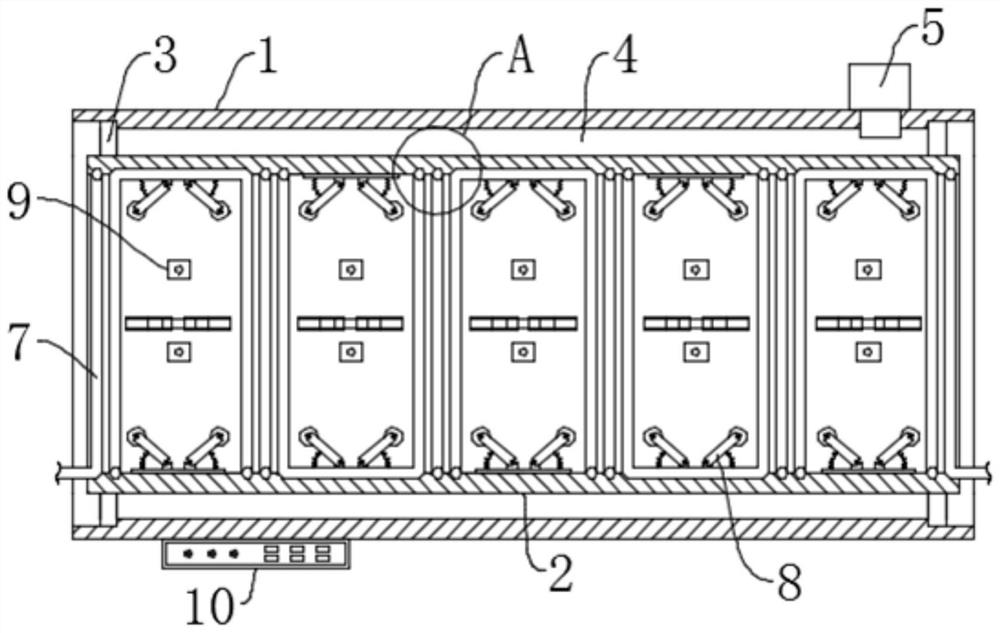

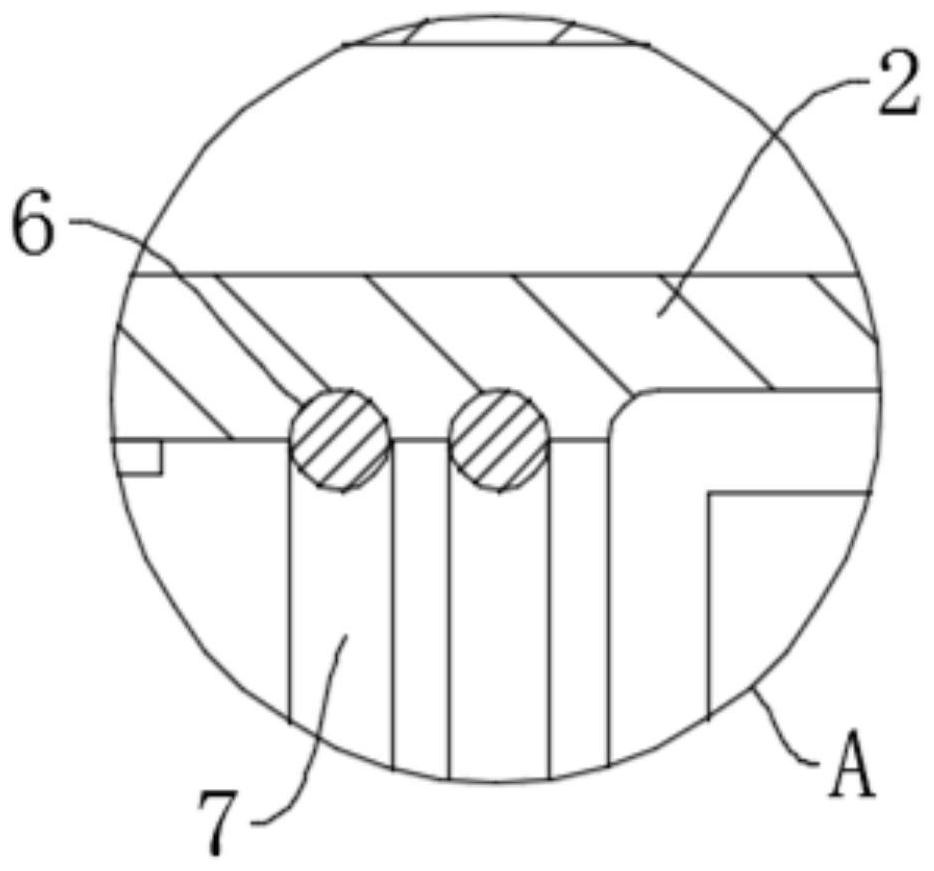

Method used

Image

Examples

Embodiment 1-9

[0034] Product performance testing:

[0035] 1) The yield strength test method refers to GB / T 228.1A-2010.

[0036] 2) The elongation test method refers to GB / T 228.1A-2010.

[0037] A precision-molded aluminum alloy material suitable for high-strength and tough structural parts of new energy vehicles, including the ingredients in the mass percentages listed in Table 1 below, and the balance is aluminum and unavoidable impurities.

[0038] Si: 2.0wt%-5.0wt%; Mg: 5.0wt%-7.0wt%; Zr: 0.2wt%-0.6wt%; Sm: 0.1wt%-0.5wt%; Gd: 0.5wt%-0.8wt%; Cu: 0.8wt%-1.2wt%; Zn: 0.6wt%-1.0wt%; Fe: <0.5wt%, silicon carbide whiskers: 3.0wt%-7.0wt%.

[0039] Table 1 is the content of each element in the aluminum alloys of Examples 1-9 and the properties of the aluminum alloys made therefrom

[0040]

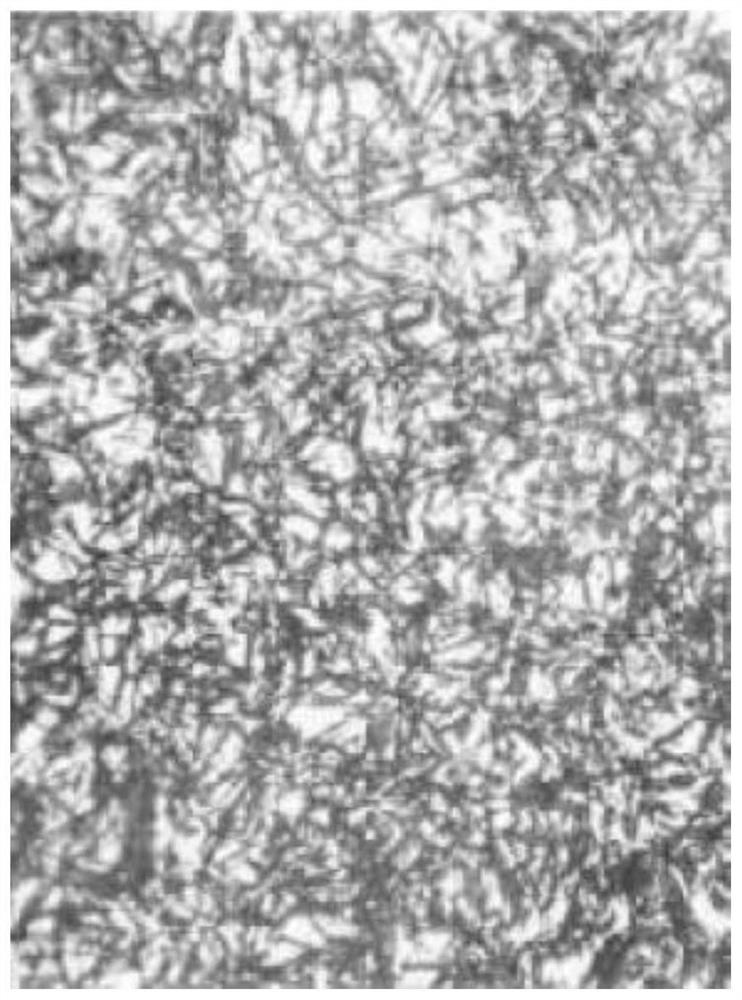

[0041] By comparing the properties of the alloys of Example 1 and Example 5, it is obvious that the tensile strength and yield strength of the alloy of Example 5 are better than that of Example 1.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com