Heat treatment method for regulating and controlling microstructure of magnesium-gadolinium alloy

A heat treatment method and microstructure technology, which is applied in the field of heat treatment to regulate the microstructure of alloys, can solve the problems of decreased elongation, low high-temperature mechanical properties of magnesium alloys, and increased alloy strength, so as to achieve improved mechanical properties and excellent room temperature/high temperature mechanics. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Keep the Mg-15Gd-5Er-5Zn-0.5Zr alloy at 550°C for 100h, then air-cool for 30min, then put it into the furnace for the second heat preservation treatment, the heat preservation temperature is 525°C, the heat preservation time is 90h, and then air-cooled After 30 minutes, a large number of long rod-shaped phases were formed in the alloy. The strength of the alloy at room temperature was 450 MPa, and the elongation was 25%. At 350°C, the strength was 260 MPa, and the elongation was 35%.

Embodiment 2

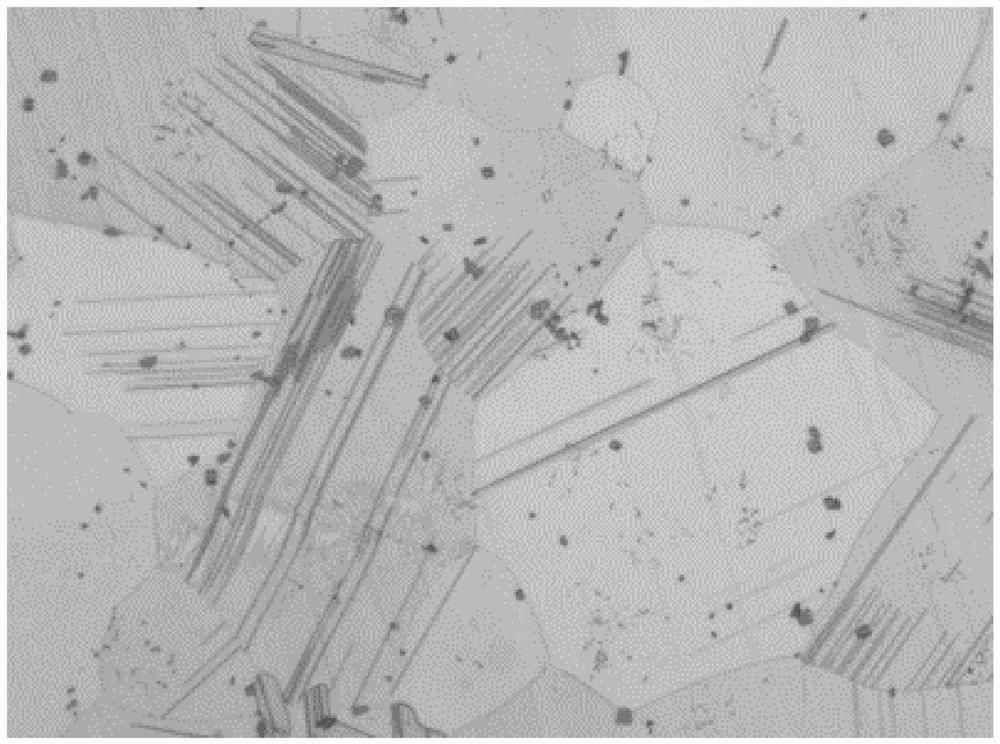

[0029] The Mg-15Gd-5Er-5Zn-0.2Zr alloy was kept at 550°C for 36h, then air-cooled for 10min, and then put into the furnace for the second heat preservation treatment. The heat preservation temperature was 525°C, the heat preservation time was 26h, and then air-cooled 10min, then carry out the third heat preservation treatment, the heat preservation temperature is 510 ℃, the heat preservation time is 20h, there are a large amount of long rod-shaped phases to form in the alloy (see figure 1 Shown), the strength of the alloy at room temperature is 420MPa, the elongation is 21%, at 350 ℃ its strength is 270MPa, the elongation is 15%.

Embodiment 3

[0031] Keep the Mg-12Gd-1Er-1Zn-0.3Zr alloy at 500°C for 10h, then air-cool for 10min, then put it into the furnace for the second heat preservation treatment, the heat preservation temperature is 475°C, the heat preservation time is 5h, and then air-cooled After 10 minutes, the alloy contains a large number of long rod-shaped phases. The strength of the alloy at room temperature is 400MPa, and the elongation is 18%. At 250°C, the strength is 220MPa, and the elongation is 23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Room temperature strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com