Optical lens support for coating machine

A technology of optical lens and coating machine, which is applied in the direction of optics, optical elements, sputtering coating, etc., can solve the problems of uneven coating and short service life, and achieve convenient loading and unloading, long service life and avoid wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

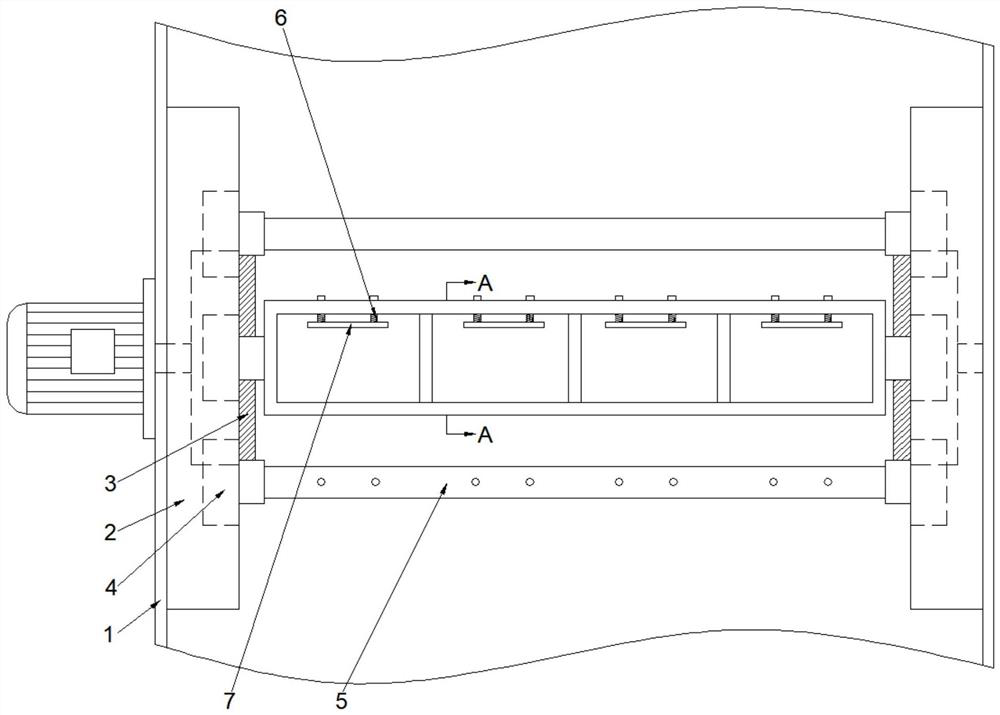

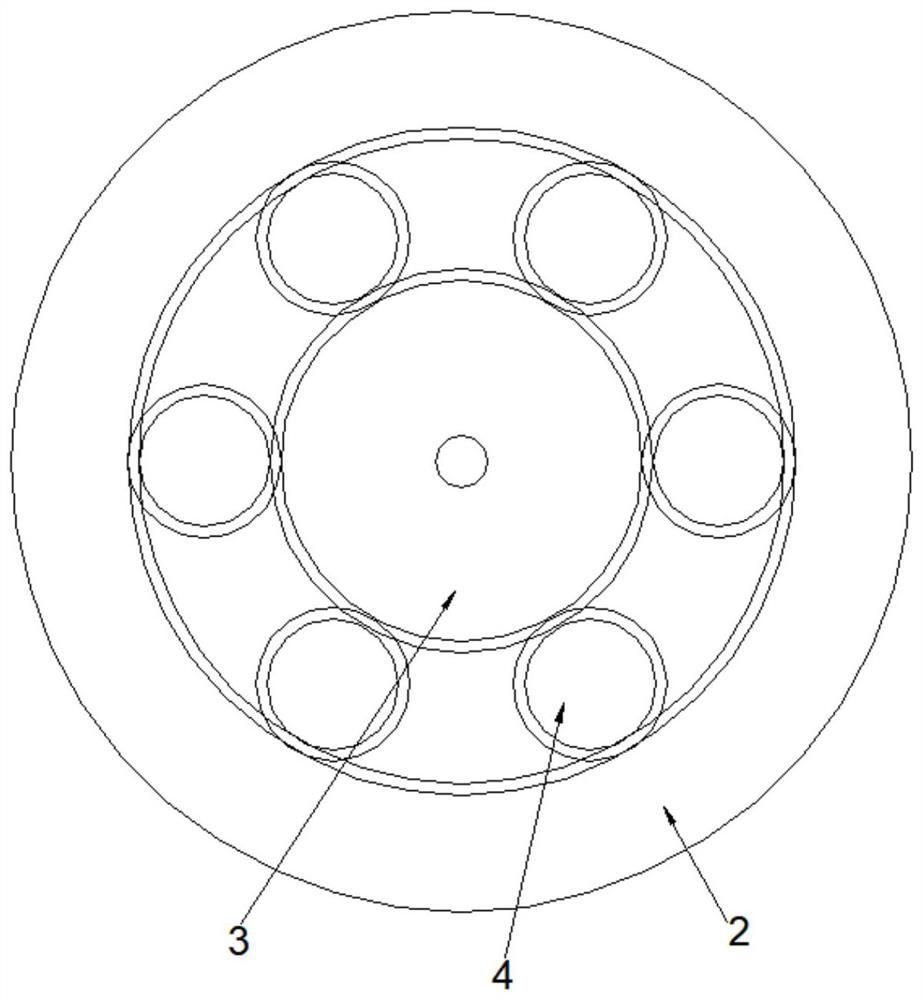

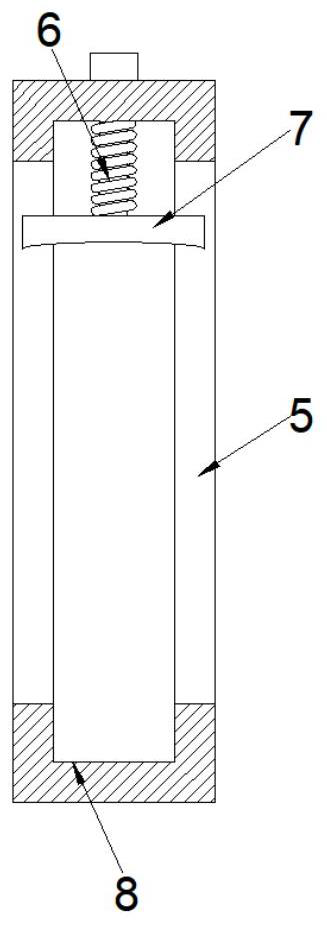

[0022] like figure 1 , figure 2 and Figure 4 As shown, in order to achieve uniform coating on both sides of the optical lens, the embodiment of the present invention proposes an optical lens holder for a coating machine, including a planetary gear assembly rotatably mounted on the inner wall of the housing 1, and the planetary gear 4 in the planetary gear assembly A connecting piece 5 is fixedly connected, and a mounting frame 9 for fixing the optical lens is detachably installed in the connecting piece 5. A circular fixing frame 10 is arranged in the mounting frame 9, and a circular fixing frame 10 is arranged in the fixing frame 10 along the axis mirror symmetrically toward the axis. The arc-shaped sheet 11 is convex in the direction, and the distance from the middle of the arc-shaped sheet 11 to the axis of the fixed fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com