Bearing with wear-resistant protection function and using method thereof

A technology of bearings and protective covers, which is applied in the direction of rotating bearings, bearings, ball bearings, etc., can solve the problems of reducing the service life of the device, not having a wear-resistant protection structure, and bearing wear, so as to avoid oil leakage and ensure service life , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

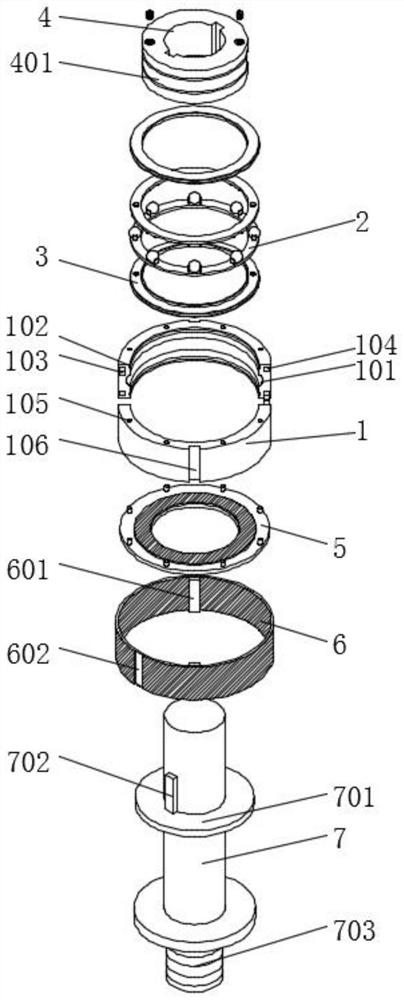

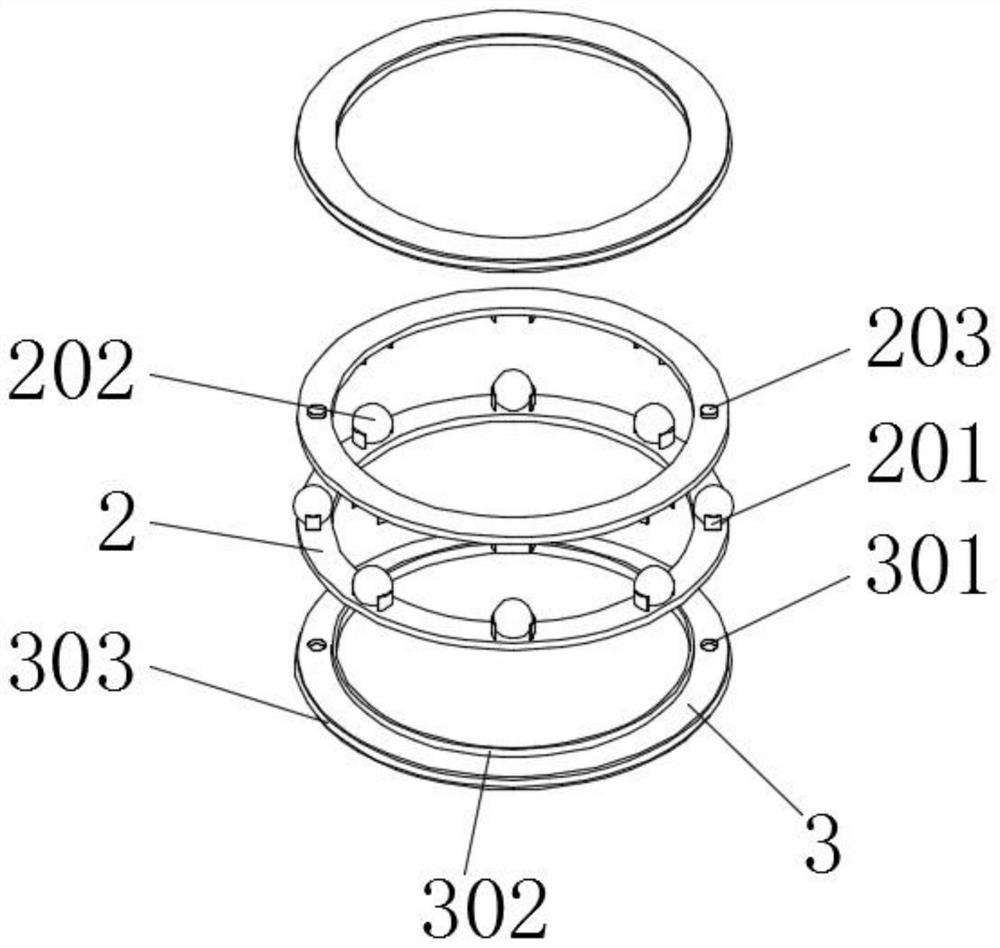

[0043] Embodiment 1 includes an outer assembly ring 1, a support ring 2 and a closure cover 3. The inner side of the outer assembly ring 1 is provided with two sets of fitting grooves 102 arranged up and down, and the inner sides of the two sets of fitting grooves 102 are fitted Fitting ring 303 is installed, and the inner side of two groups of said fitting rings 303 is equipped with closed cover 3, and the inner side of described closed cover 3 is installed with closed collar 302, and closed collar 302 is set on the outside of inner ring 4, two The opposite surfaces of the closed cover 3 of the group are all provided with symmetrically distributed limiting grooves 301, two groups of support rings 2 are installed on the opposite surfaces of the closed cover 3, and positioning blocks 203 are installed on the outside of the two groups of support rings 2, and the positioning blocks 203 Fitted and installed on the inner side of the limit groove 301, the opposite surfaces of the two...

Embodiment 2

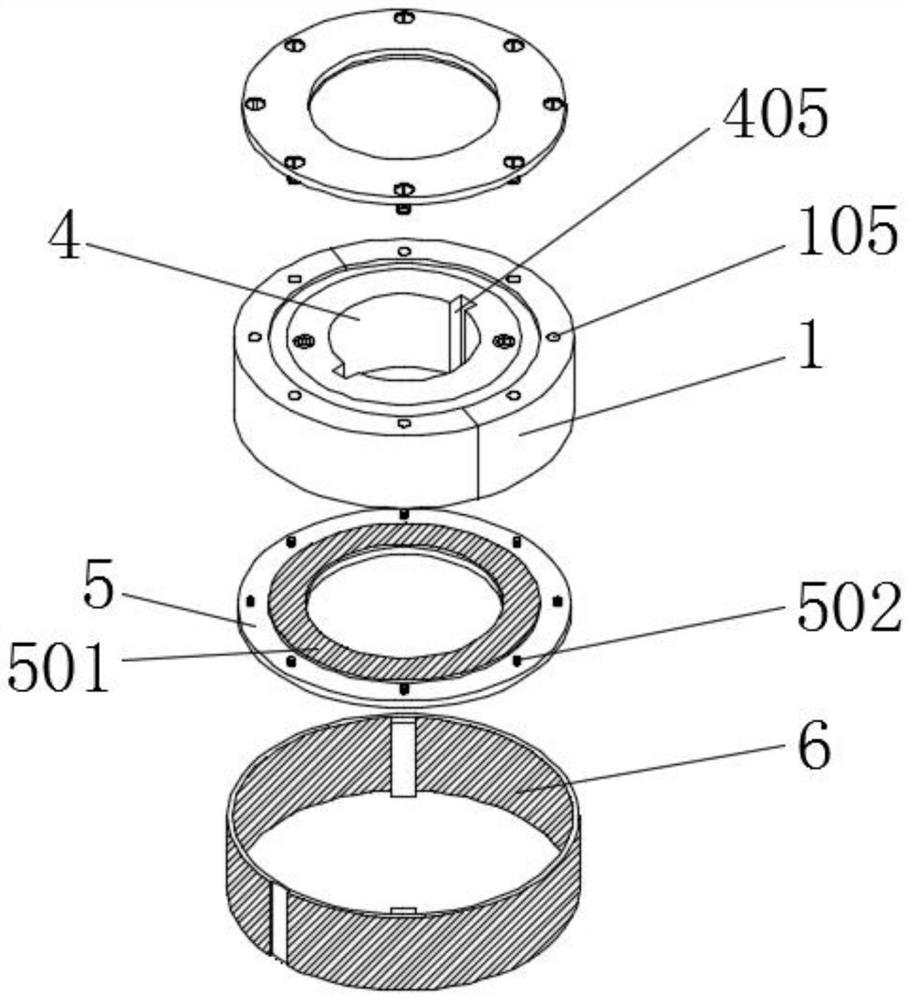

[0045] Embodiment 2 includes an outer assembly ring 1, a support ring 2 and a closure cover 3. An inner ring 4 is installed on the inner side of the anti-friction guide groove 401, and a threaded oil injection hole 402 is opened on the top of the inner ring 4. The threaded The inner side of the oil injection hole 402 is threaded with a threaded closing plug 404, and the bottom of the threaded oil injection hole 402 is equipped with an oil guide tube 403, which is installed inside the inner ring 4, and one end of the oil guide tube 403 runs through the anti-friction guide groove 401 The worker aligns the oil injection structure with the threaded oil injection hole 402 to drive the inner side, injects the lubricant into the inside of the oil guide pipe 403 through the thread oil injection hole 402, and the oil guide tube 403 transmits the lubricant to the anti-friction guide groove 401, and the lubrication The lubricant is injected into the inside of the bearing device, and the f...

Embodiment 3

[0047] The third embodiment includes the outer assembly ring 1, the outer side of the outer assembly ring 1 is covered with a rubber ring 6, the inner side of the rubber ring 6 is installed with a positioning piece 601, and the positioning piece 601 is fitted in the inner side of the positioning groove 106, so that The outside of the rubber ring 6 is provided with a card slot 602. The user fits the positioning piece 601 on the rubber ring 6 inside the positioning groove 106, and the outer assembly ring 1 positions the outer rubber ring 6 through the positioning groove 106 to ensure that the rubber ring 6 The stability of the ring 6, the rubber ring 6 is fit and connected with the external structure through the slot 602, and the friction force of the rubber ring 6 and the positioning of the slot 602 ensure the normal use of the transmission on the device.

[0048] see figure 1 , an embodiment provided by the present invention: a bearing with wear protection and its use method; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com