Multi-path lubricating grease filling intelligent distribution valve

A technology of lubricating grease and intelligent distribution, which is applied in the direction of lubricating oil control valve, lubricating oil input, distribution device, etc., can solve the problems of heavy workload, large number of operating joints, hidden dangers of mechanical operation, etc., and achieve the effect of prolonging mechanical life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

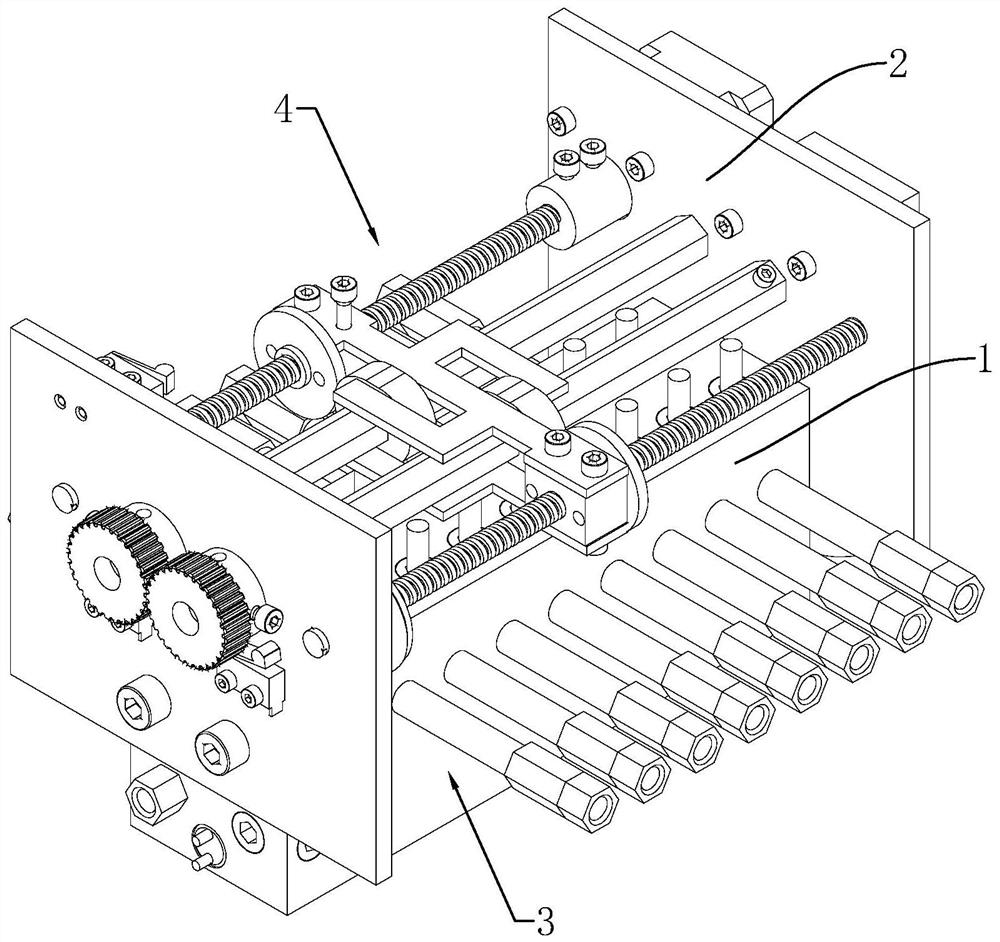

[0030] Such as figure 1 As shown, a multi-channel lubricating grease filling intelligent distribution valve includes a main valve body 1, and side plates 2 are arranged on both sides of the main valve body 1. The main valve body 1 is provided with a filling device 3 for filling grease, and a position selection device 4 for selecting the pin shaft or bearing that needs to be filled with grease.

[0031] 1. Filling device 3

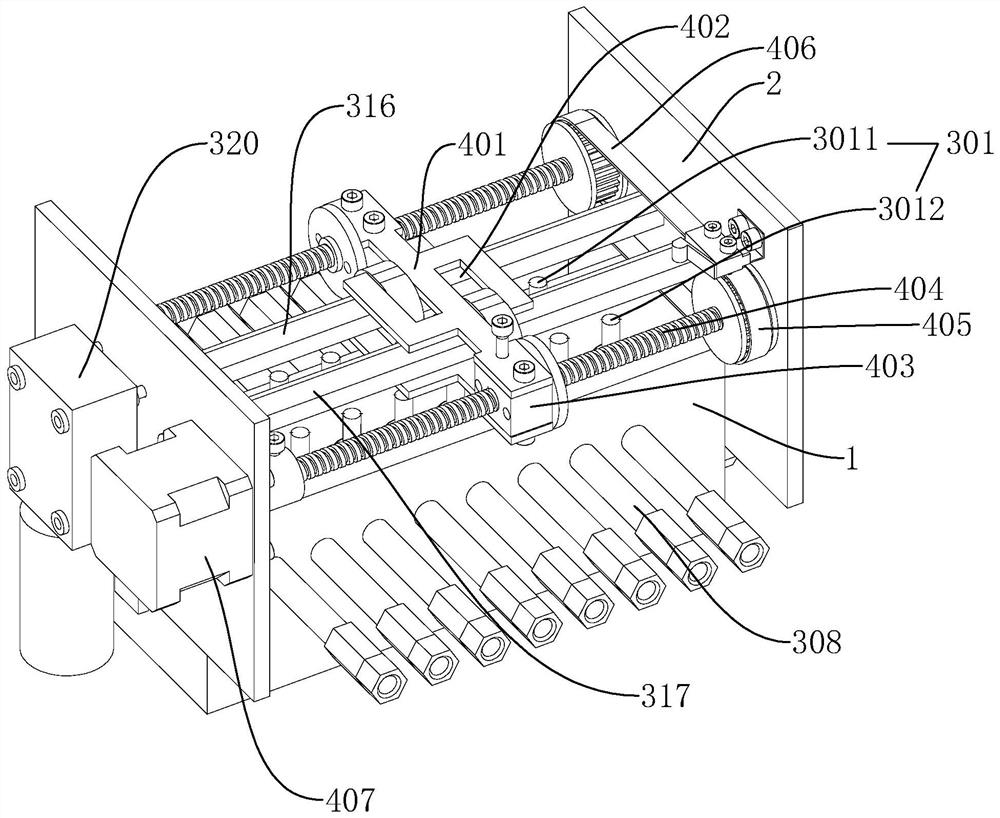

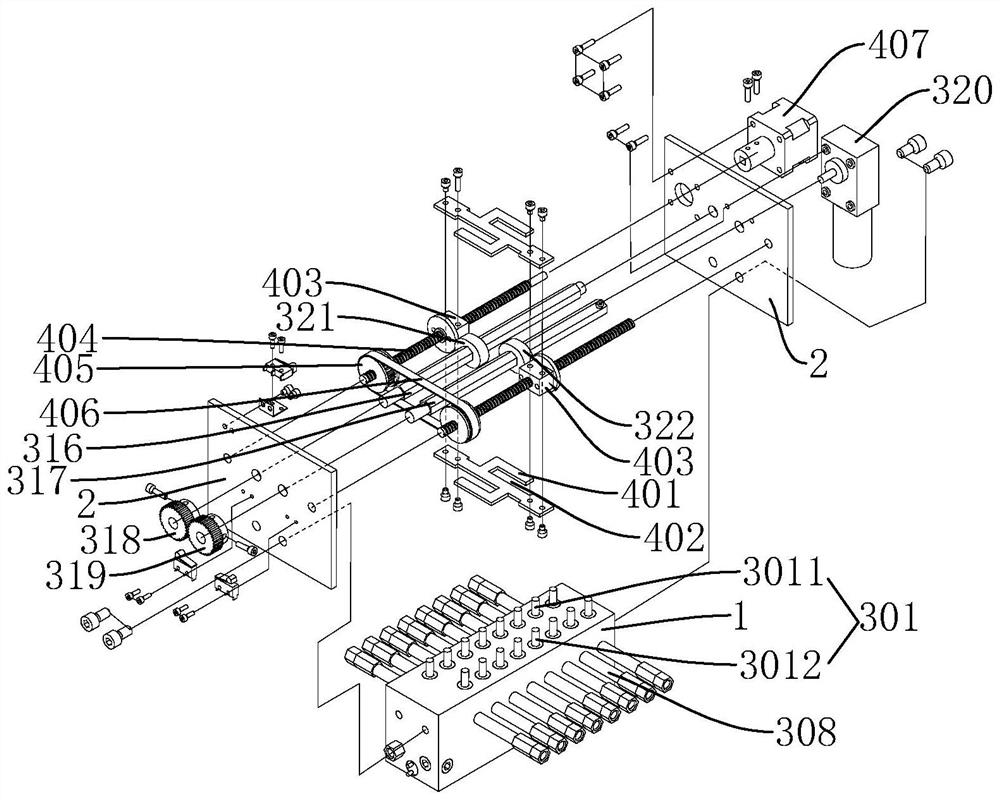

[0032] Such as figure 2 , image 3 As shown, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com