A burner protected by inert gas

An inert gas and burner technology, which is applied in the direction of burners, lighting and heating equipment, etc., can solve the problems of no anti-static device, reduce safety, and harm people on the side, so as to improve resource utilization and fully stable combustion , the effect of preventing static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

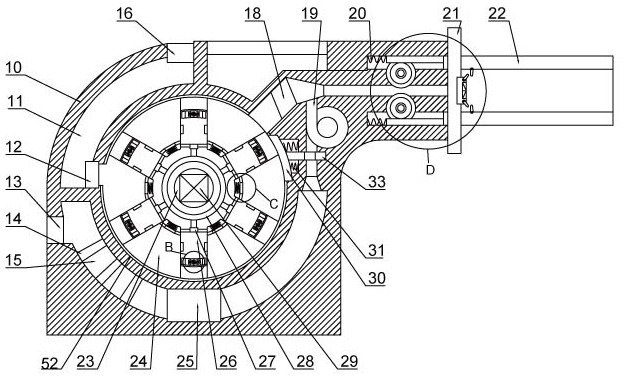

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

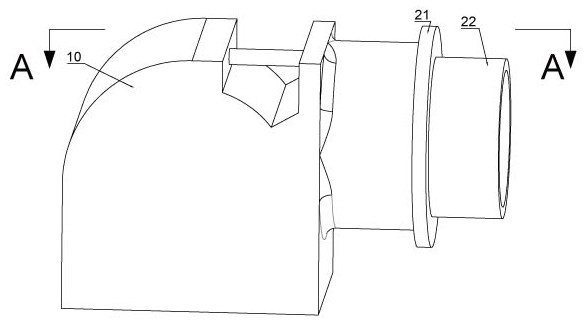

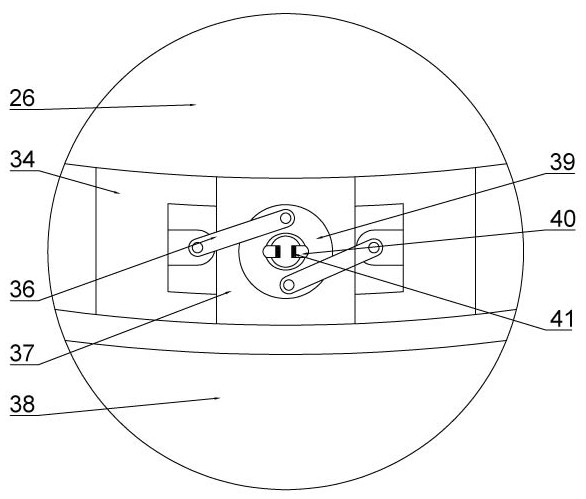

[0027] Such as figure 1As shown, a burner protected by an inert gas includes a housing 10, a spray chamber 24 is provided in the housing 10, a spray device is provided in the spray chamber 24, and the spray device is used for extrusion after the oil is atomized. The spray motor 29 is fixed outside the rear side wall of the spray chamber 24, and the output end of the spray motor 29 is fixedly provided with a spray shaft 23. Gas filling, the spray block 26 is provided with a heat absorbing device, the heat absorbing device is used to prevent the device from overheating, the lower side of the housing 10 is provided with an air spray chamber 15, and the air spray chamber 15 is provided with an air spray device, which is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com