Vegetable food processing and sterilizing equipment and regulation and control method

A technology of sterilization equipment and food processing, applied in food processing, food science, application and other directions, can solve the problems of cross-contamination of bacteria and viruses, waste of sterilizing liquid and cleaning liquid resources, etc., and achieve the effect of reducing cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

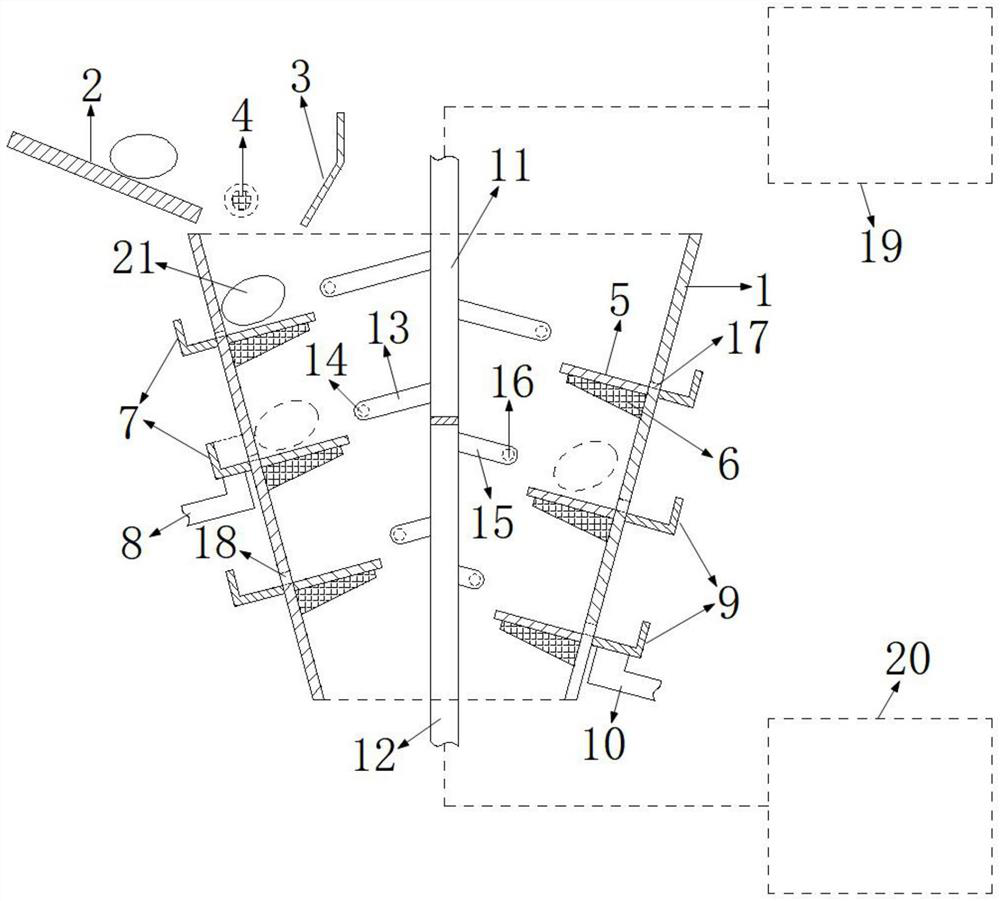

[0032] see figure 1 , figure 2 , in the present invention, the outer conveying mechanism 2 is provided, and the outer conveying mechanism 2 can adopt a conventional conveyor belt, and the conveying belt can be lower near the sterilizing cone barrel 1 end, and when the fruit dishes come out from the end side of the outer conveying mechanism 2 The photoelectric probe 4 just in time can sense the fruit dish to pass through, and the control system of the whole sterilizing cone barrel 1 has just started, and the stop plate 3 prevents the fruit dish from falling outside the sinking spiral plate 5.

[0033] After the fruit falls into the sterilizing cone barrel 1, it begins to roll and spiral down on the sinking spiral plate 5, and is cleaned with sterilized and high-volume [relative to the antibacterial liquid] water [such as the spray amount of the antibacterial liquid is 5ml / time] , then the amount of cleaning liquid sprayed is 10ml / time or 15ml / time or 20ml / time, etc.], and the...

Embodiment 2

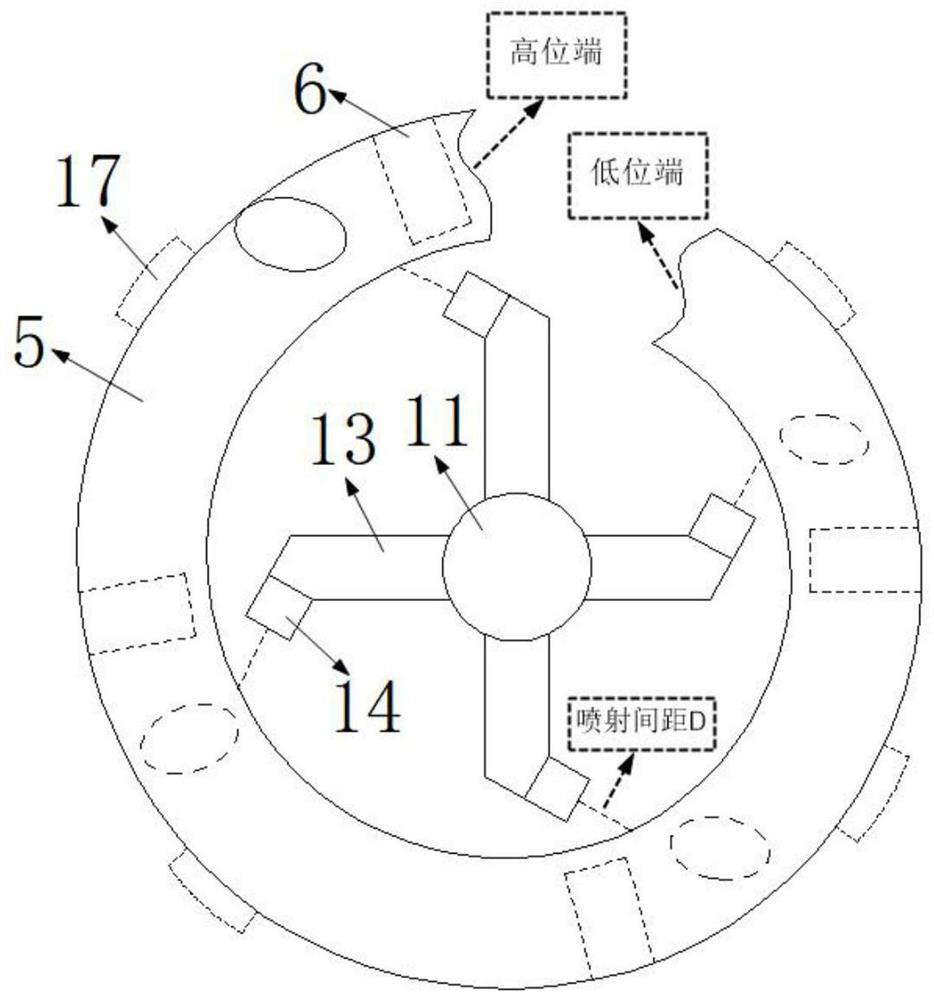

[0036] see figure 1 , figure 2, in the present invention, the sterilizing cone barrel 1 is divided into two functional areas, the upper zone is the antibacterial liquid spraying sterilization area, the lower floor is the cleaning liquid spraying cleaning area, and a fruit moves in a spiral direction from the antibacterial liquid spraying sterilization area of the upper layer area , rolling constantly occurs during exercise, and a plurality of antibacterial liquid tilting nozzles 14 spray the fruit with all-round antibacterial liquid. Equally, after a fruit enters the cleaning liquid spraying cleaning area from the antibacterial liquid spraying sterilization area, the cleaning liquid sprays a plurality of cleaning liquid inclined nozzles 16 in the cleaning area to clean the fruit in all directions.

[0037] Bacteriostatic liquid spraying sterilization area: start from the area corresponding to the first bacteriostatic liquid inclined nozzle 14, and end at the area correspon...

Embodiment 3

[0040] see figure 1 , figure 2 , in the present invention, during the process of the fruit dish moving from the current pressure sensing module 6 to the next pressure sensing module 6, the antibacterial liquid inclined nozzle 14 and the cleaning liquid inclined nozzle 16 will continue to spray, and the liquid remaining in the fruit will be cleaned To prevent the residual liquid with bacteria from contaminating the next fruit, so that the continuous fruit sterilization and cleaning effect is better.

[0041] In the present invention, when the fruit passes through the pressure sensing module 6, the control system acquires the pressure signal of the pressure sensing module 6 and analyzes it, and then controls the nozzle at the corresponding position to spray the corresponding amount. Although the process time is very short , but there is an instantaneous time interval, and setting the pressure sensing module 6 slightly upstream of the spraying direction of the nozzle is also us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com