Rice bran removing equipment based on rice fine processing

A rice bran and rice technology, which is applied in the field of rice bran removal equipment, can solve the problems of low efficiency of rice bran removal, affecting the quality of rice finishing, and poor rice bran removal effect, so as to improve the removal effect, avoid residual phenomena, and improve the screening effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

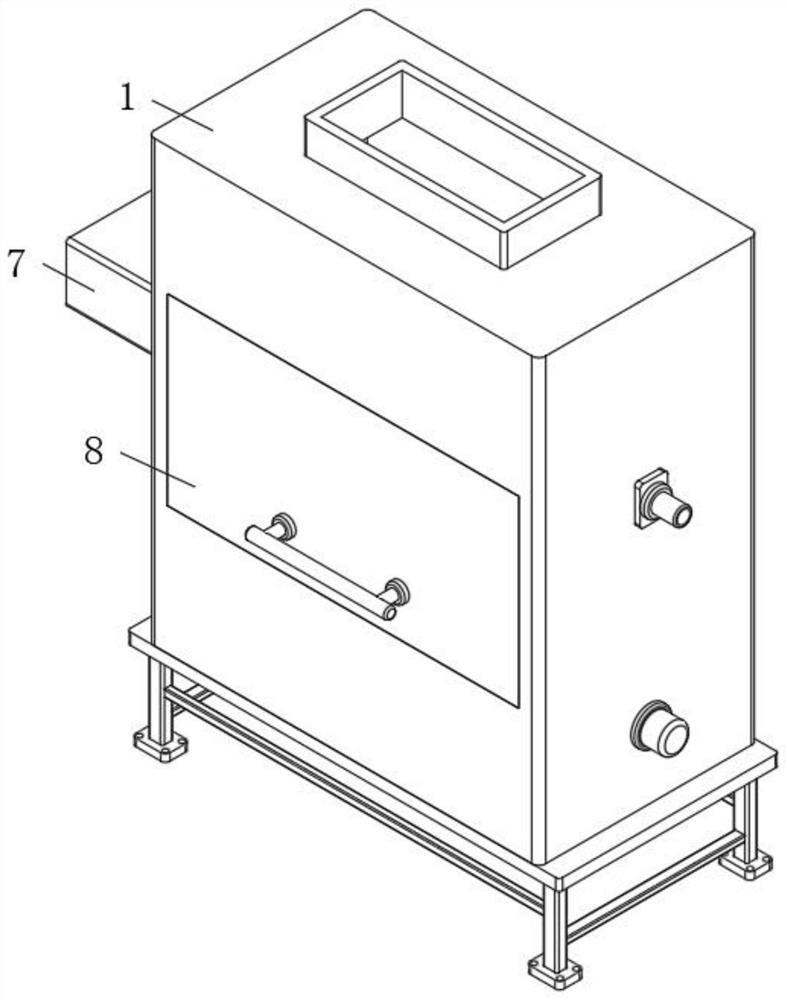

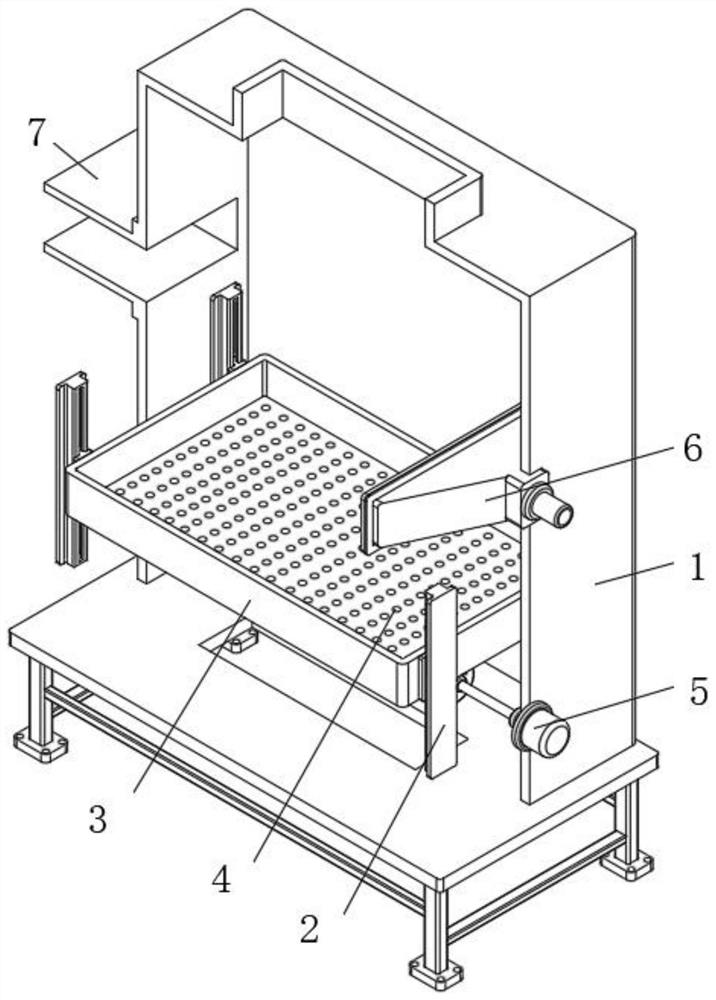

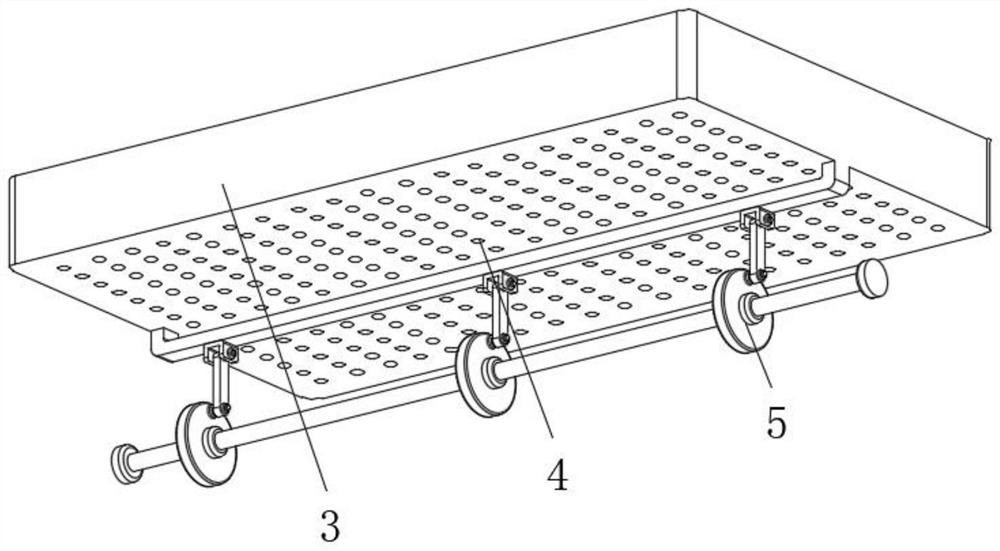

[0032] Figure 1-5 It is an embodiment of the present invention: a rice bran removal device based on rice finishing, including a cabinet 1, a sliding assembly 2 is fixedly installed on both sides of the inner wall of the cabinet 1, and a bearing box 3 is installed on the movable end of the sliding assembly 2, The bottom wall of the carrying box 3 is provided with a plurality of evenly distributed sieve holes 4, and the casing 1 is provided with a drive assembly 5 for driving the carrying box 3 to realize up and down reciprocating motion. The blowing cover 6 is blown out, and the blowing cover 6 is connected with the external fan equipment. The left side of the cabinet 1 is equipped with a miscellaneous discharge channel 7 used in conjunction with the blowing cover 6. The rice bran enters the trash discharge channel 7 under the action of the wind and is discharged to the cabinet. 1 Externally, a mechanical hatch 8 that can be opened and closed is installed on the cabinet 1, and...

Embodiment 2

[0037] Figure 1-6It is an embodiment of the present invention: a rice bran removal device based on rice finishing, including a cabinet 1, a sliding assembly 2 is fixedly installed on both sides of the inner wall of the cabinet 1, and a bearing box 3 is installed on the movable end of the sliding assembly 2, The chassis 1 is provided with a driving assembly 5 that drives the bearing box 3 to realize up and down reciprocating movement. The right side of the inner wall of the chassis 1 is fixedly installed with a blower cover 6 for blowing out the rice bran in the rice. The blower cover 6 is connected with the external fan equipment. The left side is equipped with a miscellaneous discharge channel 7 used in conjunction with the blower cover 6. The rice bran enters the miscellaneous discharge channel 7 under the action of the wind and is discharged to the outside of the cabinet 1. A mechanical hatch 8 that can be opened and closed is installed on the cabinet 1;

[0038] The slide...

Embodiment 3

[0043] Figure 1-8 It is an embodiment of the present invention: a rice bran removal device based on rice finishing, including a cabinet 1, a sliding assembly 2 is fixedly installed on both sides of the inner wall of the cabinet 1, and a bearing box 3 is installed on the movable end of the sliding assembly 2, The chassis 1 is provided with a driving assembly 5 that drives the bearing box 3 to realize up and down reciprocating movement. The right side of the inner wall of the chassis 1 is fixedly installed with a blower cover 6 for blowing out the rice bran in the rice. The blower cover 6 is connected with the external fan equipment. The left side is equipped with a miscellaneous discharge channel 7 used in conjunction with the blower cover 6. The rice bran enters the miscellaneous discharge channel 7 under the action of the wind and is discharged to the outside of the cabinet 1. A mechanical hatch 8 that can be opened and closed is installed on the cabinet 1;

[0044] The slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com