Error compensation method for industrial robot

An industrial robot and error compensation technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as poor compensation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiment of Error Compensation Method of Industrial Robots:

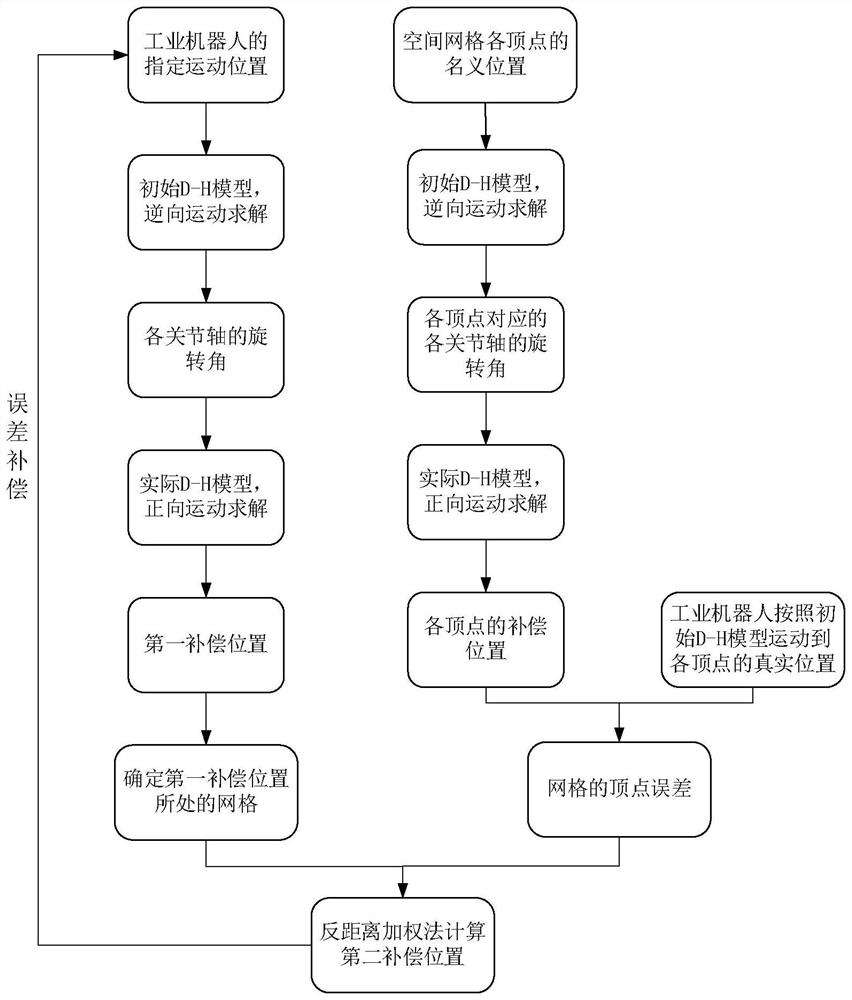

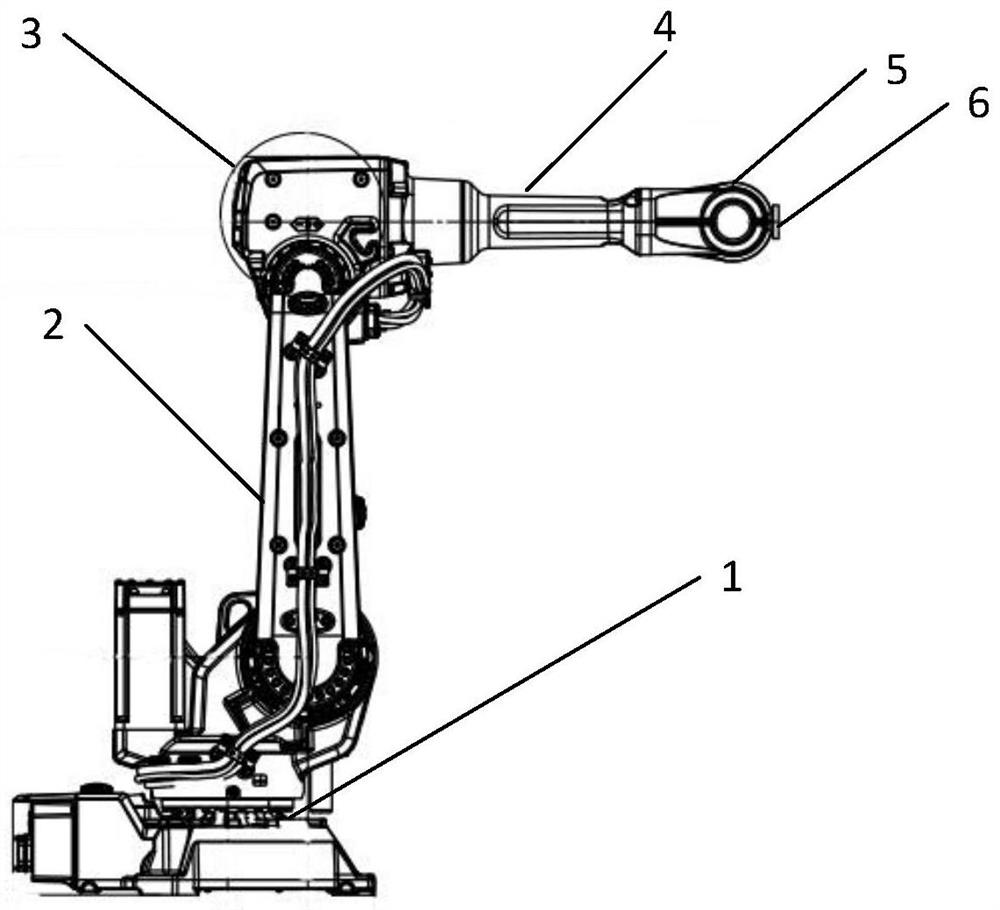

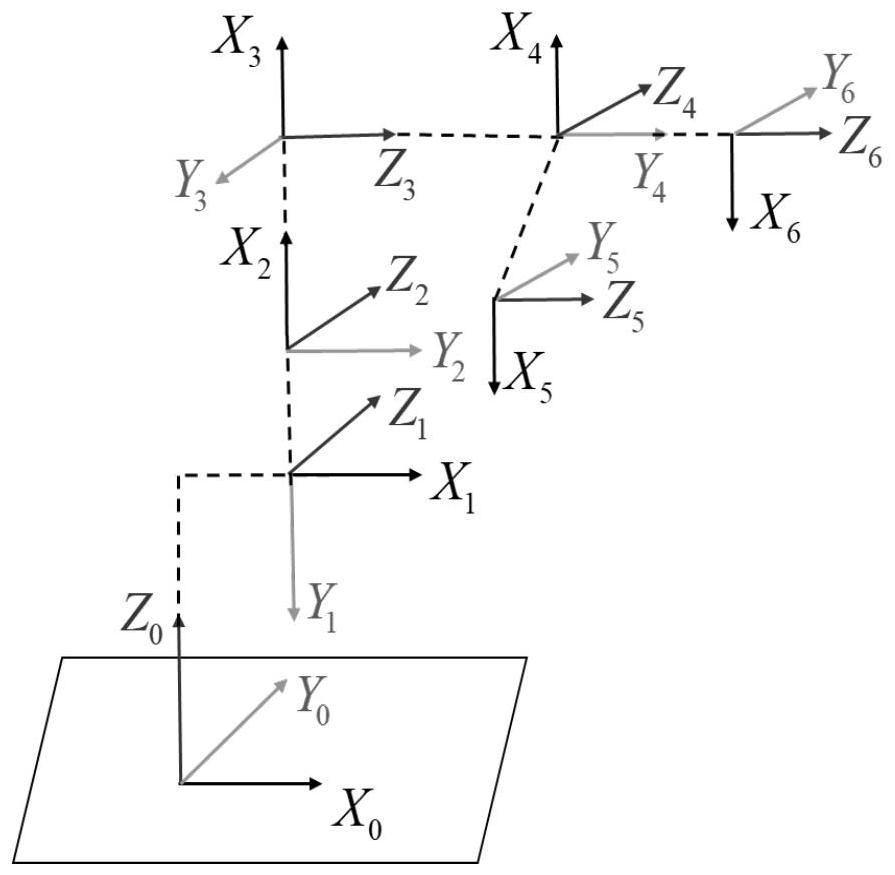

[0036] The main concept of the present invention is that the present invention combines these two ways based on an axis measurement method and space mesh method compensation, specifically combined as: first obtain the actual DH model according to the axis measurement method, the specified moving position passes The initial DH model reverse motion solution and the actual DH model forward motion solve the first compensation location; secondly, the sports space of the industrial robot is grided, and the compensation position of the grid is obtained through the actual DH model. Combined with the high-precision measuring instrument, the real position of the grid vertex is solved by common point conversion to obtain an error of each mesh vertex; according to the grid in the first compensation location, the vertex error according to the grid is obtained by the forward distance weighting method The error at a compensat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com