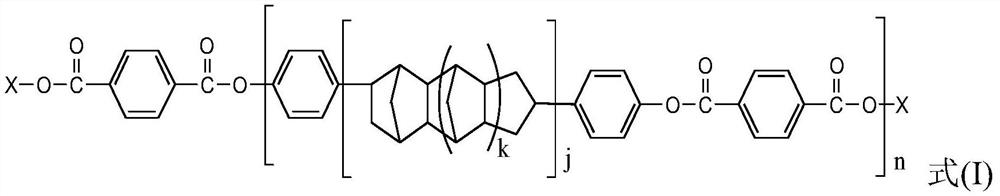

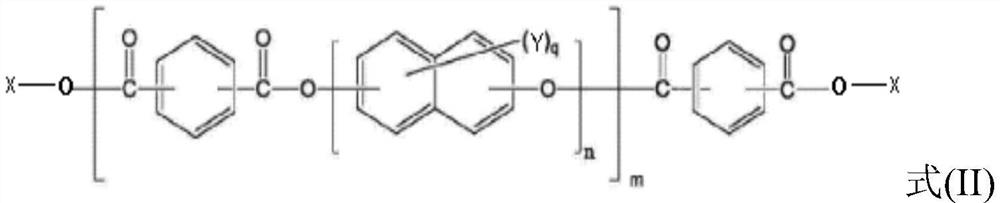

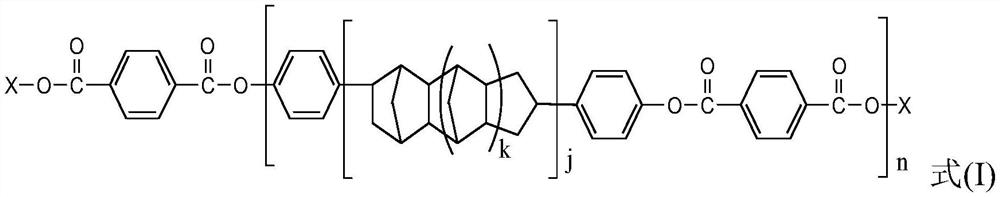

Resin composition, prepreg containing same, laminated board and printed circuit board

A resin composition, printed circuit board technology, applied in the field of laminates and printed circuit boards, resin composition, can solve the problem of general interlayer adhesion, achieve no resin enrichment problem, excellent interlayer The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides an epoxy resin copper-clad laminate, which is prepared from a resin composition, and the resin composition includes: (A) a DCPD epoxy resin with a softening point of less than 95°C, (B ) active ester resin, (C) phosphorus-containing phenolic resin and (D) inorganic filler.

[0058] The preparation method of above-mentioned laminated board comprises the steps:

[0059] Get a container, add 100 parts by weight of epoxy resin KES-7680M75, 22.3 parts by weight of active ester resin HPC-8000-65T, 22.3 parts by weight of active ester resin HPC-8000L-65MT, 54.2 parts by weight of phosphorus-containing phenolic resin JFH-Z3101P60, 30wt% (85.2 parts by weight, accounting for 30wt% of the total of epoxy resin, active ester resin, phosphorus-containing phenolic resin and inorganic filler) inorganic filler DS2032A, pre-dissolved curing accelerator DMAP, continue to stir evenly, Finally, a solvent is used to adjust the solid content of the liquid to 65%, th...

Embodiment 2-11

[0062] The manufacturing process of Example 2-11 is the same as that of Example 1, and the formula composition and its physical properties are shown in Table 1-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com