Method for acquiring load distribution state of multi-row roller turntable bearing in real time

A technology for slewing bearings and load distribution, which is applied to rolling contact bearings, rotating bearings, bearings, etc., can solve problems such as bearing structure failure, slewing bearing structure damage, and error in the force state, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

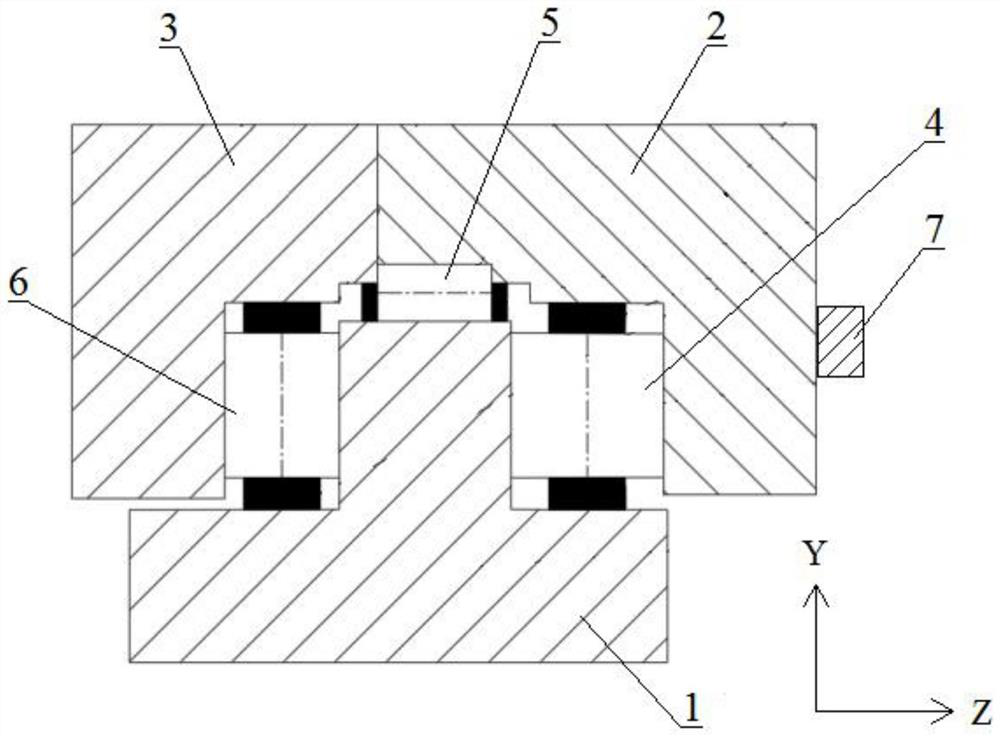

[0039] see figure 2, the multi-row roller slewing bearing in this application is a typical three-row cylindrical roller slewing bearing, including an inner ring 1 arranged radially and an outer ring, and the outer ring includes a first outer ring 2 arranged axially And the second outer ring 3, wherein the second outer ring 3 is arranged closer to the working surface (such as the cutter head) than the first outer ring 2, and along the direction away from the working surface, between the inner ring 1 and the outer ring Auxiliary push rollers 6, radial rollers 5 and main push rollers 4 are arranged in sequence along the axial direction, the main push rollers 4 are located between the first outer ring 2 and the inner ring 1, and the auxiliary push rollers 6 Located between the second outer ring 3 and the inner ring 1, the radial roller 5 is located at the junction of the first outer ring 2 and the second outer ring 3, the rolling of the main push roller 4 and the auxiliary push r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap