Fault positioning system and method for GIL equipment connected with cable

A technology for equipment faults and cable connection, applied in fault locations, information technology support systems, and fault detection according to conductor types, etc., can solve problems such as the reduction of high-voltage cable wave impedance, achieve precise positioning, improve anti-interference ability, and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The application will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present application.

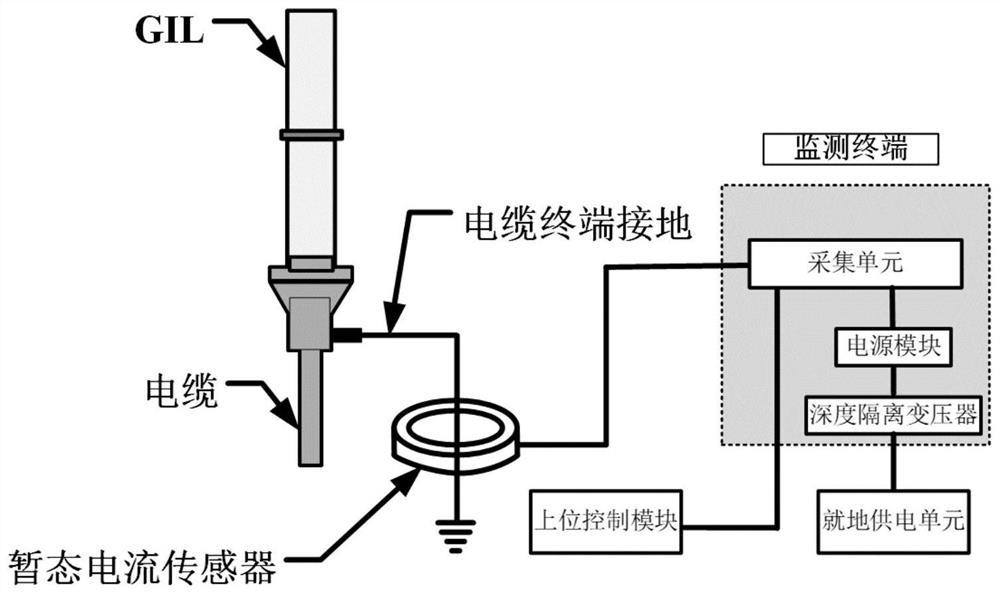

[0039] Such as figure 1 As shown, a fault location system for GIL equipment connected with cables of the present invention includes a transient current sensor, a monitoring terminal and an upper control module;

[0040] The transient current sensor and the monitoring terminal are respectively used for sensing and monitoring the transient current at the outer shielding ground wire of the cable terminal connected to the GIL equipment;

[0041] During specific implementation, the transient current sensor is installed at the outer shielding ground bar of the cable terminal connected to the GIL equipment, and performs transient current sensing based on the principle of high-frequency electromagnetic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com