High-pickup-rate flexible chip mounting mechanism for adsorbing thin and brittle chips

A chip and flexible technology, applied in the field of high pick-up rate flexible patch mechanism, can solve the problems of not being able to adapt to multi-materials, angle differences, easy to crush thin and brittle chips, etc., to overcome the easy to crush thin and brittle chips and improve the pick-up rate , Improve the effect of adsorption stability and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail in conjunction with the accompanying drawings:

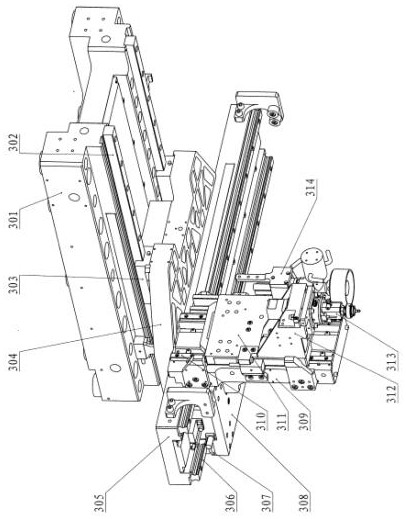

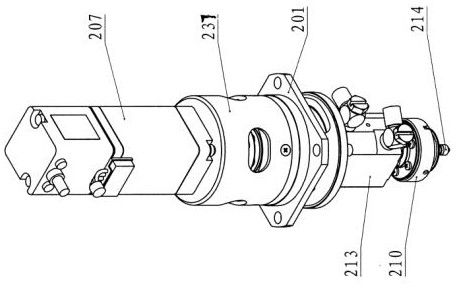

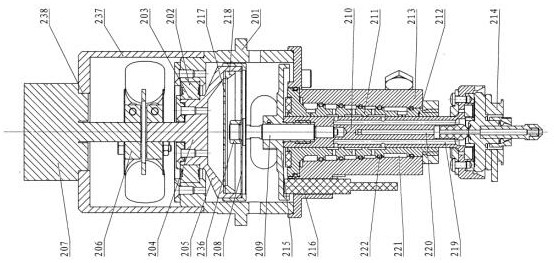

[0034] An adsorption-type crackers high chip rate pickup mechanism flexible patch, the Y-axis including the top plate 301 in the seat front-rear horizontal direction of the Y-axis direction is provided at the bottom surface of the top plate 301 of the seat to the Y-axis guide 302, in connection to the Y-axis guide 302 hanging Y-axis direction of the slider 303, the slider 303 in the Y-axis to the bottom surface of the transition plate 304 fixedly connected to, the bottom surface of the transition plate 304 is fixedly connected with the left and right in the horizontal direction X-axis to the top of the base plate 305, the bottom surface of the X-axis to the top of the seat plate 305 is provided with an X-axis direction rail 306, the guide shaft 306 in the X-X direction is connected with hanging slider 307, the slider 307 in the X a bottom surface connected to a second fixed tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com