Drill bit for petroleum and natural gas applications

A technology of drill bits and cutting devices, applied in the directions of drill bits, drilling tools, earth-moving drilling, etc., can solve the problems of reduced drilling efficiency, excessive operating temperature, and increased risk of lateral vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

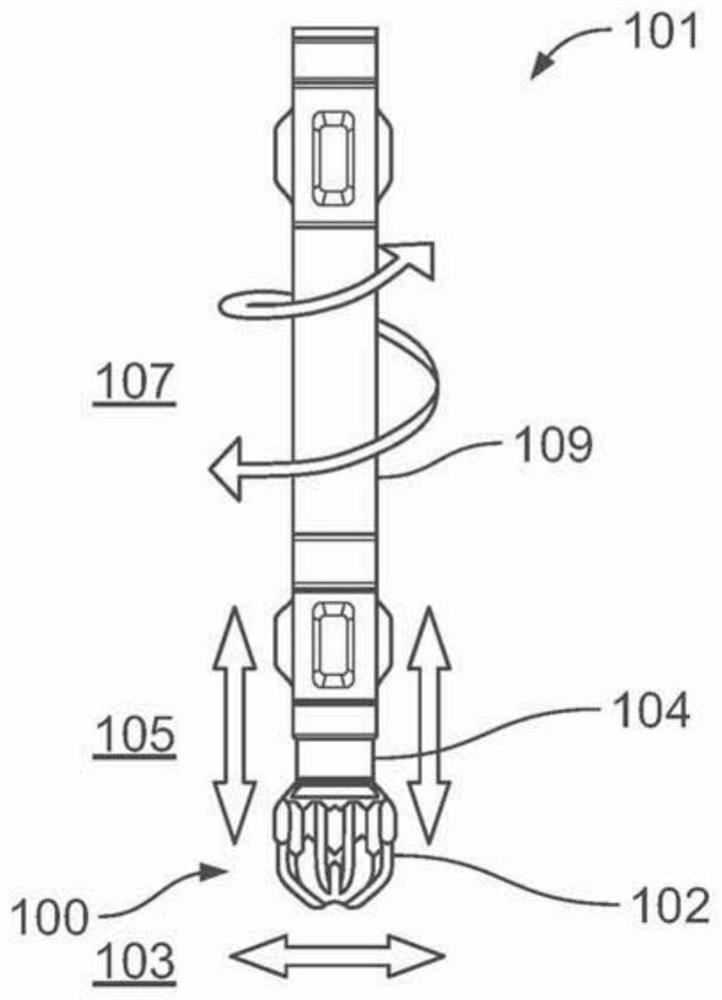

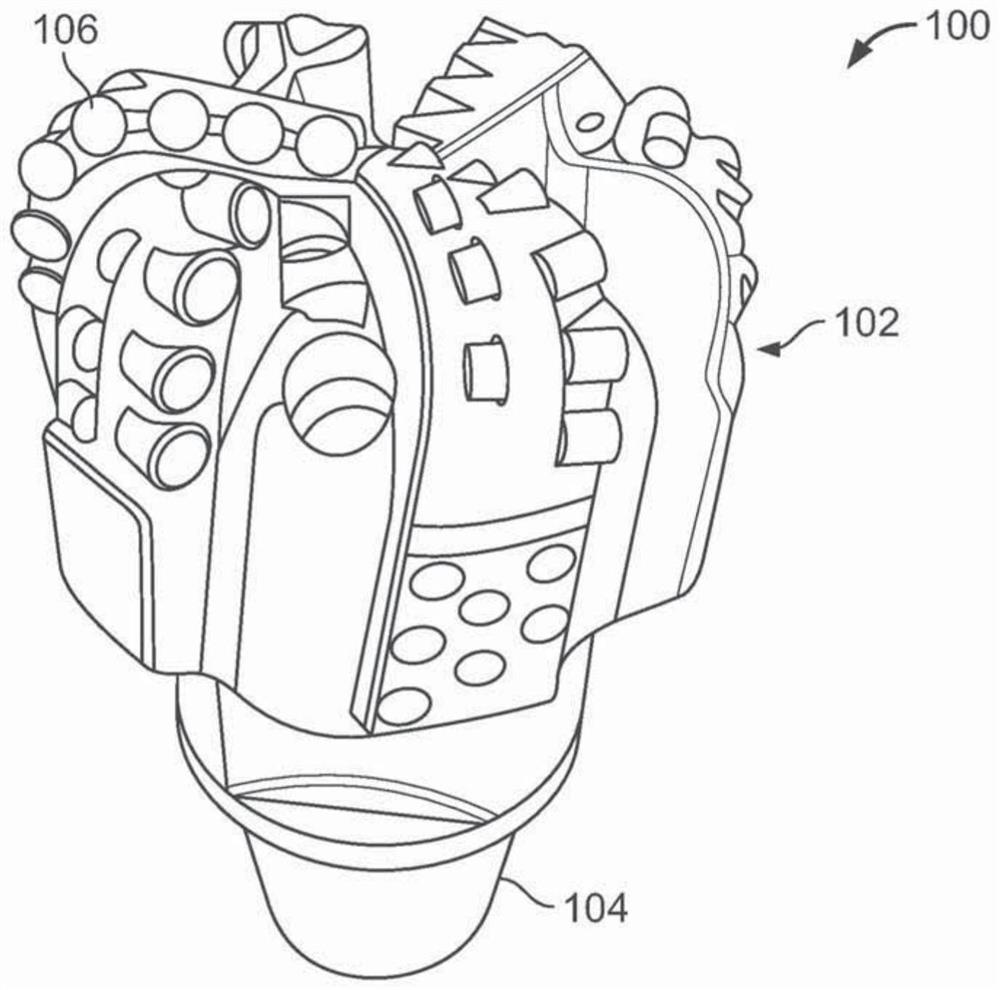

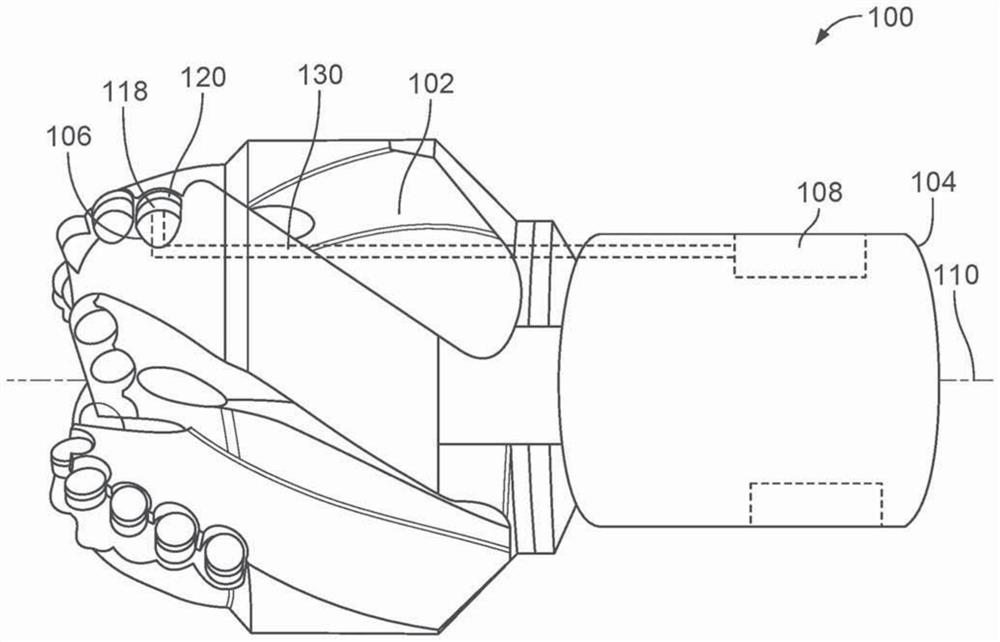

[0038] Figure 1-Figure 3 Shown is a drill bit 100 designed to drill into (eg, one or more of cut, crush, and scrape) a rock formation to produce or further form a wellbore. Drill bit 100 is mounted to the bottom end of drill string 101 and may experience various types of vibrations during operation, including lateral 103 , vertical 105 , and torsional 107 vibrations. Such vibrations may cause mechanical wear of the drill bit 100 as the drill bit 100 impacts the rock formation forcefully.

[0039] The drill bit 100 includes a cutting body 102 and a coupling member 104 (eg, a bit short) that connects the cutting body 102 to a shaft 109 of a drill string 101 . The cutting body 102 is equipped with a plurality of cones 106 (e.g., PDC cones), and the coupling member 104 is equipped with a microelectronic unit 108 that is in electrical communication with the cones 104 and includes a microprocessor and a microcontroller. . The cutting body 102 generally has a length of about 0.26...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap