Cooling forming system for high-moisture fibrosis vegetable protein

A vegetable protein, cooling molding technology, applied in the processing field of vegetable protein imitation meat products, can solve problems such as poor product quality, and achieve the effect of improving product quality and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

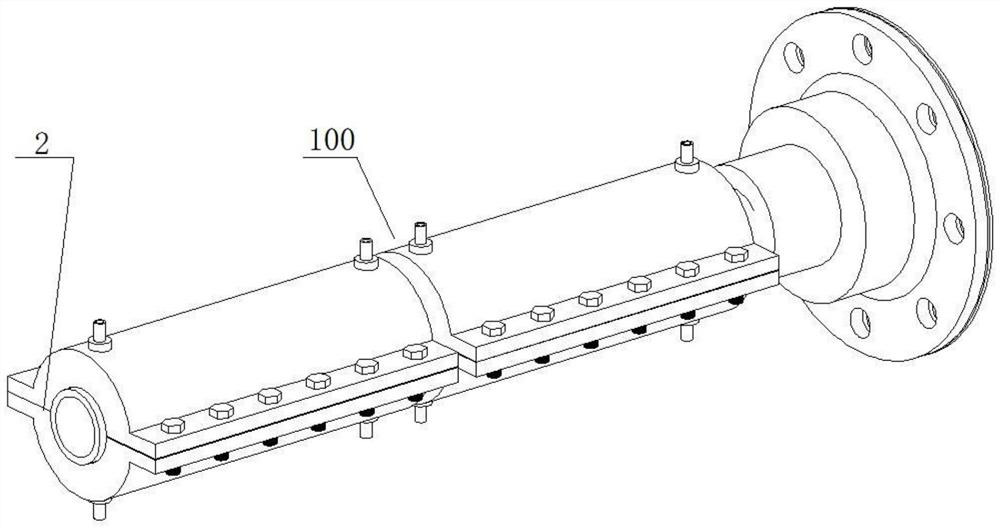

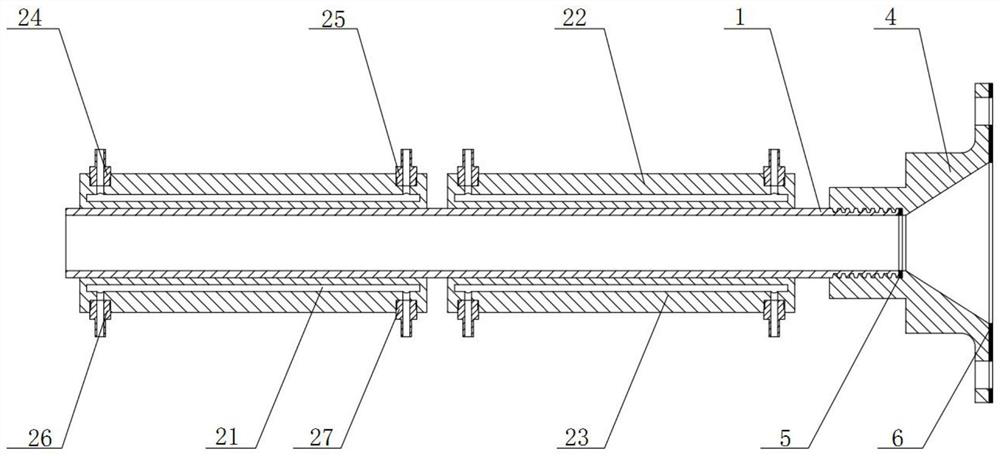

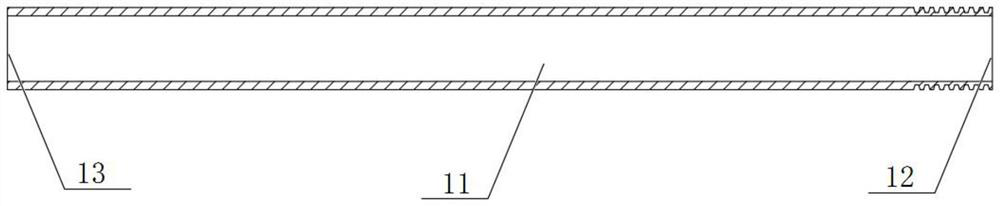

[0052] Such as Figure 1-Figure 8 As shown, this embodiment provides a cooling molding system 100 for high-moisture fibrous vegetable protein, including a molding die 1, a cooling sleeve 2 and a cooling medium temperature control device 3, and the molding die 1 is internally provided with a A protein forming inner cavity 11 for forming protein raw materials, one end of the protein forming inner cavity 11 is provided with a feed port 12, and the other end is provided with a discharge port 13; the cooling sleeve 2 is detachably mounted on the outside of the forming die 1, and the cooling sleeve 2. There are multiple sets along the flow direction of the vegetable protein raw material in the protein forming cavity 11; any cooling sleeve 2 is provided with a cooling medium channel 21 for the cooling medium to flow in the cylinder wall; the cooling medium temperature control device 3 can The cooling medium channel 21 transports the cooling medium and controls the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com