Compression molding die for side surfaces of equal-density slender pipe fittings

A technology of side pressing and forming molds, applied in the direction of manufacturing tools, presses, etc., can solve the problems of unable to meet product design requirements, unable to press slender tube bodies with the same density of tube wall powder, and poor tube wall density, etc. It can achieve the effect of convenient and quick pressing, solving the problem of slender pipe fittings that cannot be of equal density, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

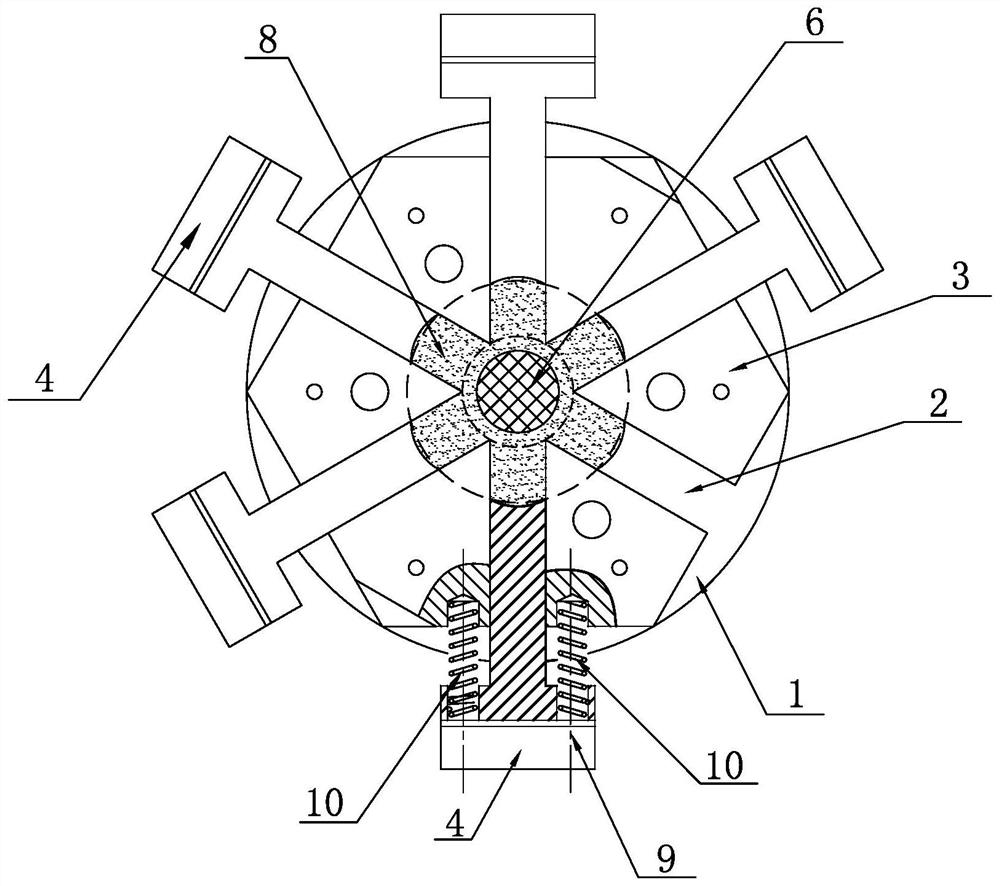

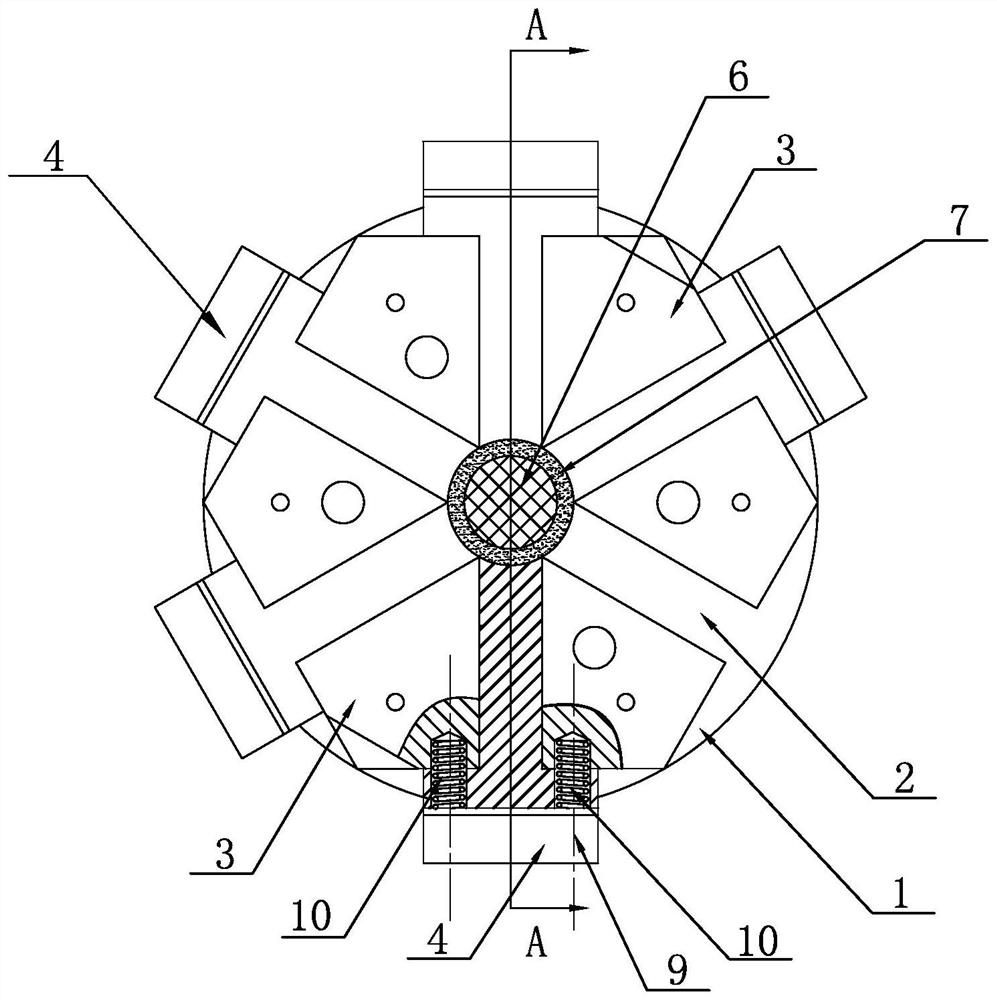

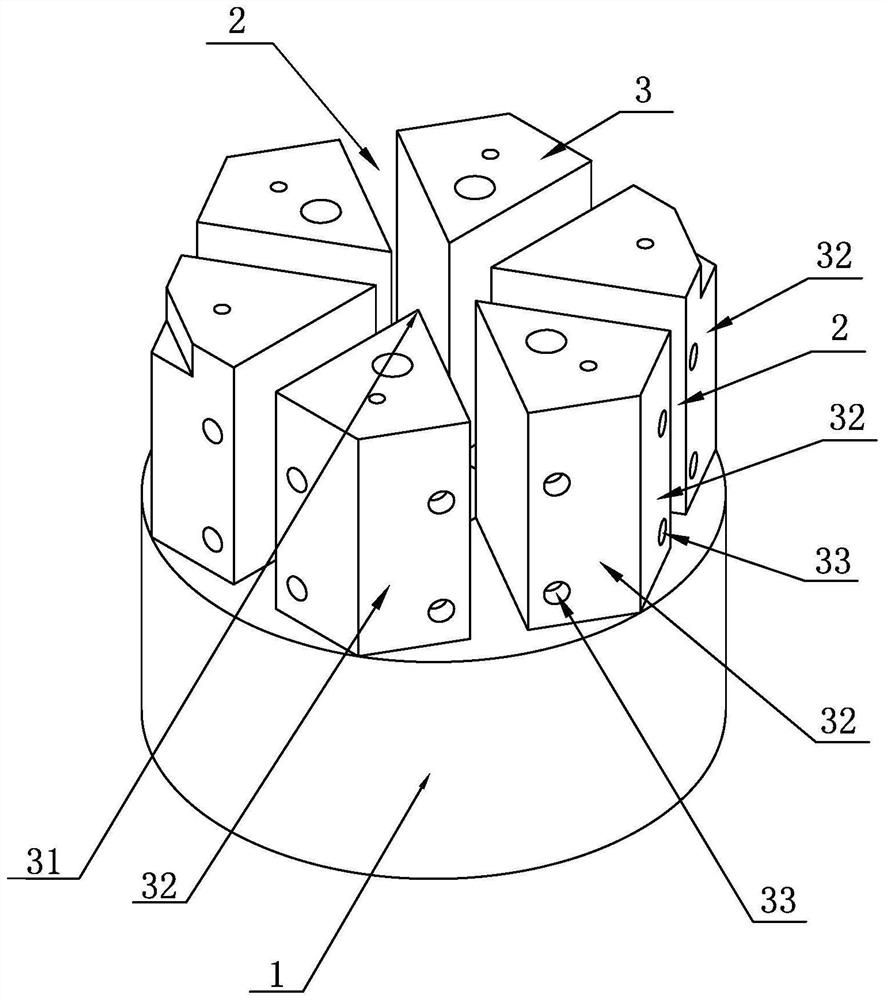

[0030] One kind of the elongated tubular member isopycnic side pressing mold, such as Figure 1-10 , The base including a seat, sliding grooves 2, six angular seat 3, six sides sliding pressing block 4, the pressing member 5 and the side mold mandrel 6, mold 6 fixedly mounted on the mandrel holder base 1 central location, six angular seat 3 disposed uniformly in the circumferential direction on the same circumference with the center of the mold with mandrels 6, and disposed at the upper end surface of the foundation block 1 is formed between two adjacent corners seat 3 a sliding groove 2, the outer diameter of the same sharp angle seat 3 seat diameter of the circle in which the tip 31 to be pressed to pipe 7; the side surface of the slide guide block 41 includes a pressing block 4, the pressure block 42, arc shaped 43, 44 and limit surface active surfaces 45, 43 forming the outer diameter of the arc diameter tube 7 to be pressed is the same, the side sliding pressing block 41 of th...

Embodiment 2

[0032] Example 2: Example 1 except that: the side surface and disposed radially slidably compact stopper structure 3 between different angular seat 4, in this example: a slide block 4 in the briquetting pressure side a mating side surface 42 and sharp corners 32 between the seat 3 of the return spring 10, the bottom of the slide 4 is provided on the side of the compact limiting chutes 47, the upper end surface of the seat base 1 is provided with a radial stop member 34. Such as Figure 8 Indicated.

[0033] In the above two embodiments, in order to reduce side movement of the sliding frictional resistance between the clamps 3 and 4 pointed base, with the slot to prevent the powders during pressing to squeeze the both sides, the jamming phenomenon will produce both , would cause a waste of powder, provided in the side surface 4 of the sliding pressing block 48 on the concave side with the powder leakage cavity 49, the depth can be set manually concave drain chamber 49 the powder is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concave depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com