Steelmaking converter flue with ash deposition prevention structure

A steelmaking converter and anti-ashing technology, which is applied in the field of steelmaking converter flue, can solve the problems of general anti-ashing effect, influence of converter use, flue blockage, etc., so as to improve ash cleaning effect, ensure discharge effect, increase The effect of flue gas velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

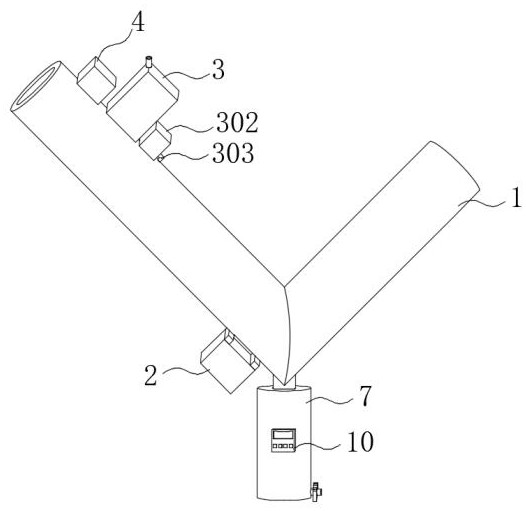

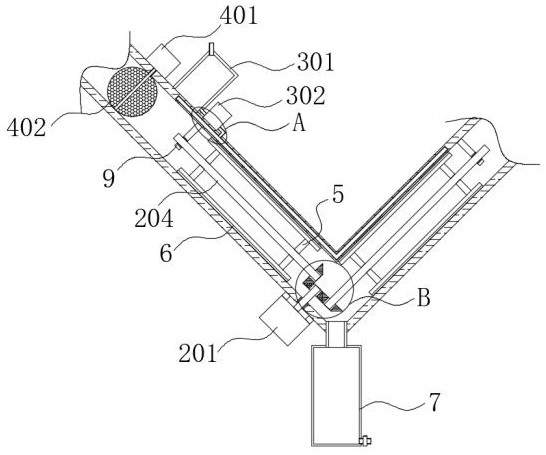

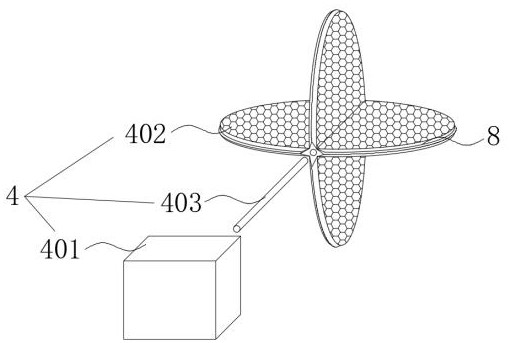

[0027] see Figure 1 to Figure 5 , the present invention relates to a steelmaking converter flue with an anti-dust structure, comprising a smoke exhaust pipe 1 and a drive mechanism 2, the inside and outside of the smoke exhaust pipe 1 are provided with a spray assembly 3, the inside of the smoke exhaust pipe 1 A filter assembly 4 is arranged on the outer side, and eight support rods 5 are installed on the driving mechanism 2, and four cleaning brush plates 6 are installed on the eight support rods 5, and the outer sides of the four cleaning brush plates 6 are connected with the smoke exhaust pipe 1 The inner wall of the exhaust pipe 1 is in contact with the inner wall, and the front section of the smoke exhaust pipe 1 is V-shaped, and the outer side of the smoke exhaust pipe 1 is installed with a collection barrel 7 communicating with it. The setting of the smoke exhaust pipe 1 is convenient to support the whole device. During the use of the converter, the flue gas will be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com