Sulfuric acid and chloride ion corrosion resistant steel plate containing Sn and Sb and manufacturing method thereof

A technology of chloride ion corrosion and manufacturing method, which is applied in the direction of manufacturing tools, metal rolling, temperature control, etc., can solve the problems that cannot meet the requirements of corrosion resistance performance, and achieve the effect of good surface quality and cold bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

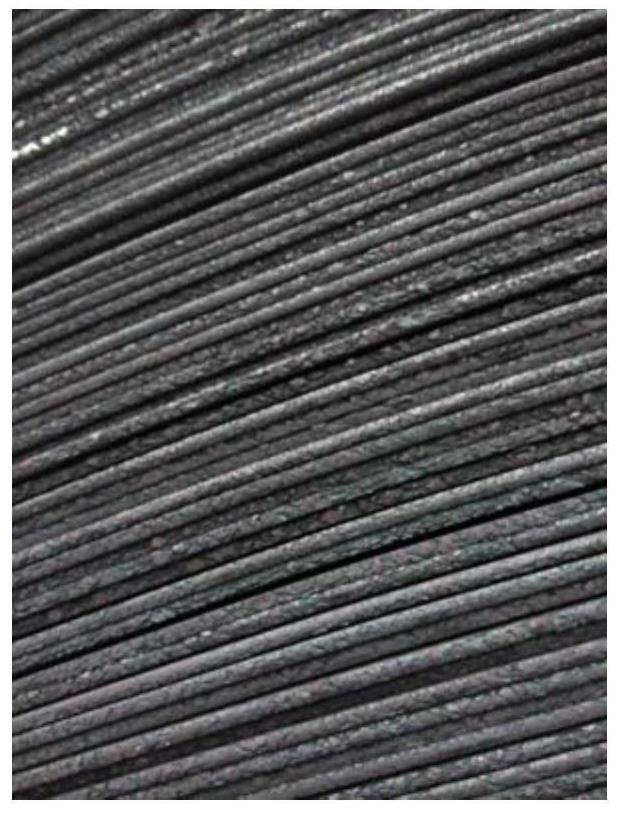

Image

Examples

Embodiment 1

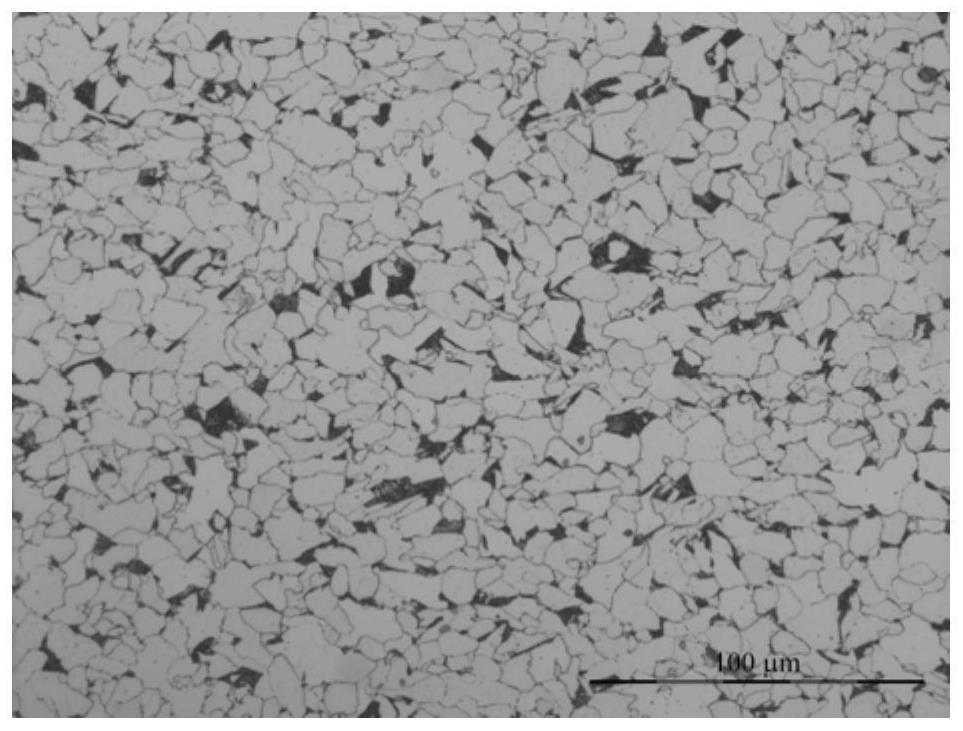

[0044] The microstructure of embodiment 1 and comparative example 5 see image 3 , Figure 4 , the volume ratio of P tissue in Example 1 is about 5.49%, the volume ratio of F tissue is about 94.51%, and the grain size is 10.5. The volume ratio of P tissue in Comparative Example 5 is about 3.12%, and the volume of F tissue accounts for The ratio is about 96.88%, and the grain size is 9.5.

[0045] Each embodiment of table 1 and comparative example steel plate composition

[0046]

[0047] Table 2 main process parameters, performance and surface quality of each embodiment and comparative example rolling process

[0048]

[0049] In Comparative Example 1 and Comparative Example 2, only the Sn content control requirement in the chemical composition is changed on the basis of Example 1, and the technical requirements of Example 1 are implemented for the rest. The chemical composition of Comparative Example 3 does not meet the requirements of the present invention, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com