Butt joint method for sealing flanges of door frame of stainless steel sealing door

A sealing flange and stainless steel technology, which is applied to the sealing device, door leaf, wing leaf frame, etc., can solve the problems of easy gaps or margins in the cladding board, difficulty in ensuring the appearance of the joint, deformation of the steel plate, etc., to achieve beautiful appearance , smooth surface, and enhanced market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

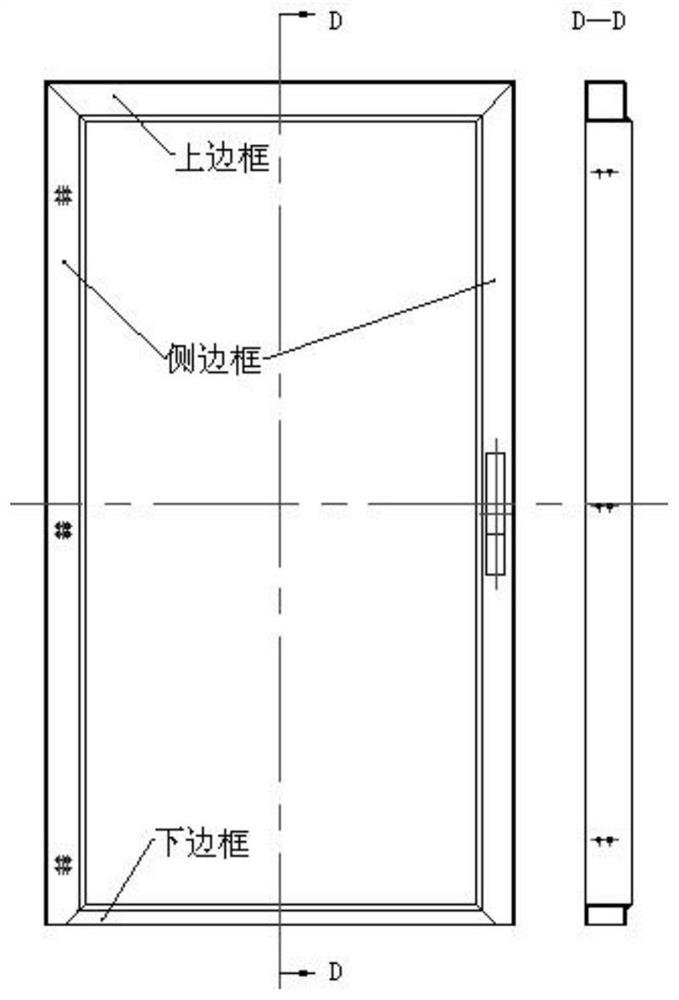

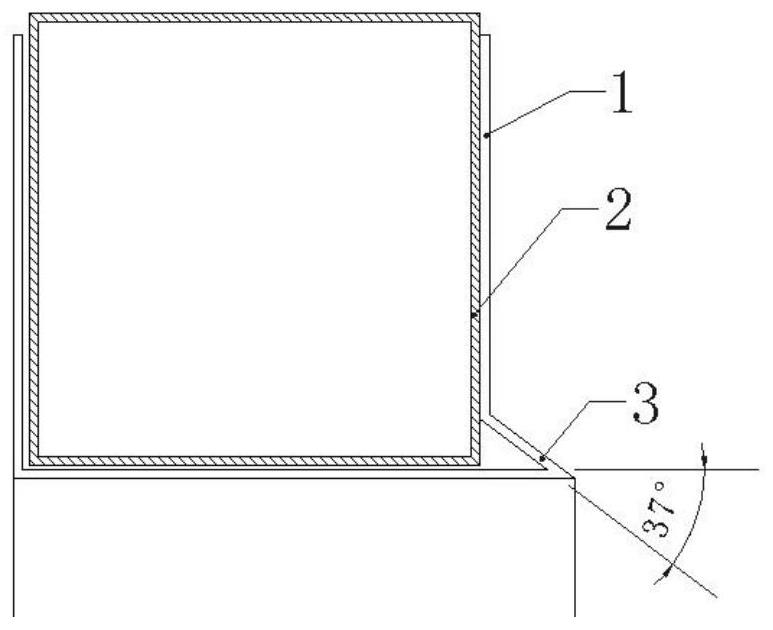

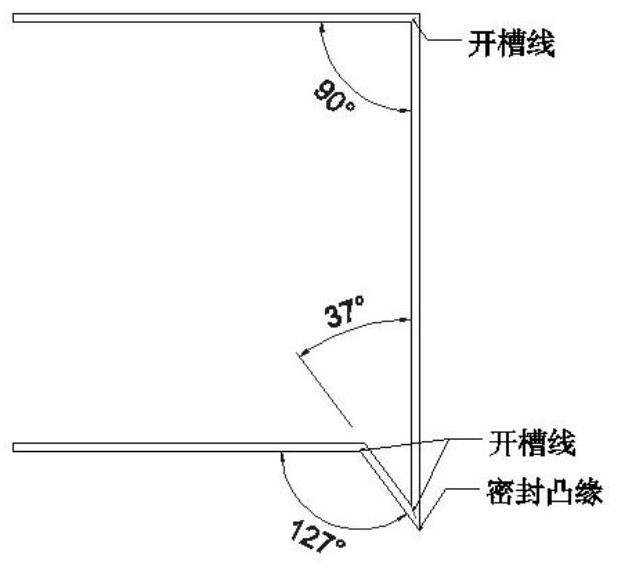

[0025] The invention discloses a sealing flange butt joint method for a door frame of a stainless steel airtight door. The sealing flange is located on the door frame, and the four corners of the sealing flange of the door frame are connected at right angles. The door frame is composed of upper and lower frames and left and right frames, as shown in FIG. figure 1 shown. The internal structure of the border is as figure 2 As shown, the inside of the frame is a stainless steel square tube, and the outside is a stainless steel cladding plate with a sealing flange. Door frame cladding structure such as image 3 As shown, the cladding plate is made of stainless steel plate through laser cutting and bending, and at the same time, the sealing fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com