Capactive micro-machined ultrasonic transducer (CMUT)-based super-low range pressure sensor and preparation method thereof

A pressure sensor, ultra-low volume technology, applied in the field of MEMS, can solve the problems of ultra-low and micro-pressure measurement applications that have not been reported, and achieve the effects of improving work performance and pressure measurement accuracy, improving sensitivity, and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

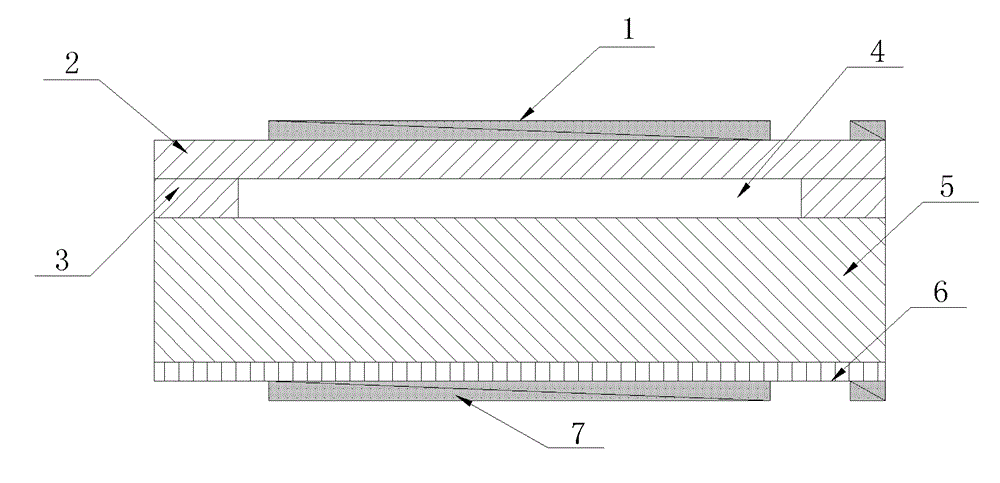

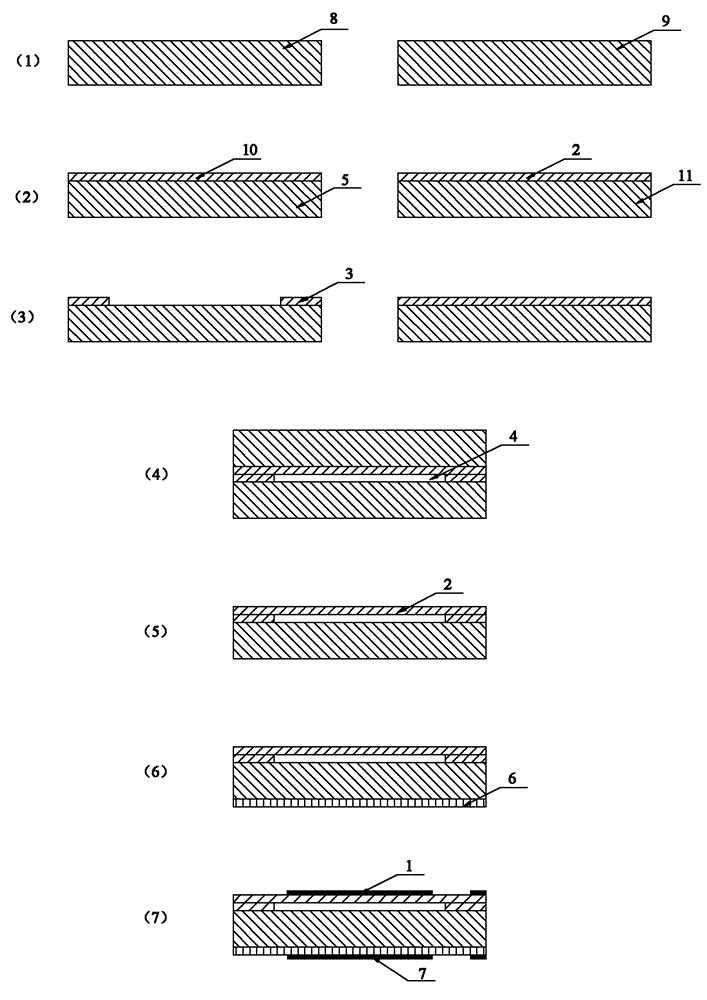

[0027] The CMUT-based ultra-low range pressure sensor and its preparation method of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0028] See attached figure 1 , The overall structure of a CMUT-based ultra-low range pressure sensor of the present invention is from top to bottom: metal aluminum upper electrode 1, silicon dioxide film 2, silicon dioxide pillar 3, cavity 4, single crystal silicon base 5. Silicon nitride insulating layer 6 and metal aluminum bottom electrode 7. The pressure sensor has simple structure, low processing difficulty, low cost, high sensitivity and good working performance, and can realize ultra-low range micro pressure measurement.

[0029] The metal aluminum upper electrode 1 is located in the middle of the silicon dioxide film 2, and its thickness should be as thin as possible while maintaining good electrical conductivity, so as to reduce the mass of the entire vibrating film composed of it and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com