Speed reducer with safety pin for mud scraper

A technology of reducer and safety pin, which is applied to mechanical equipment, components with teeth, belts/chains/gears, etc. It can solve the problems of no safety protection structure at the connection, easy mis-rotation safety accidents, etc., so as to facilitate independent disassembly The effect of replacement, avoiding safety accidents and preventing damage by external force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

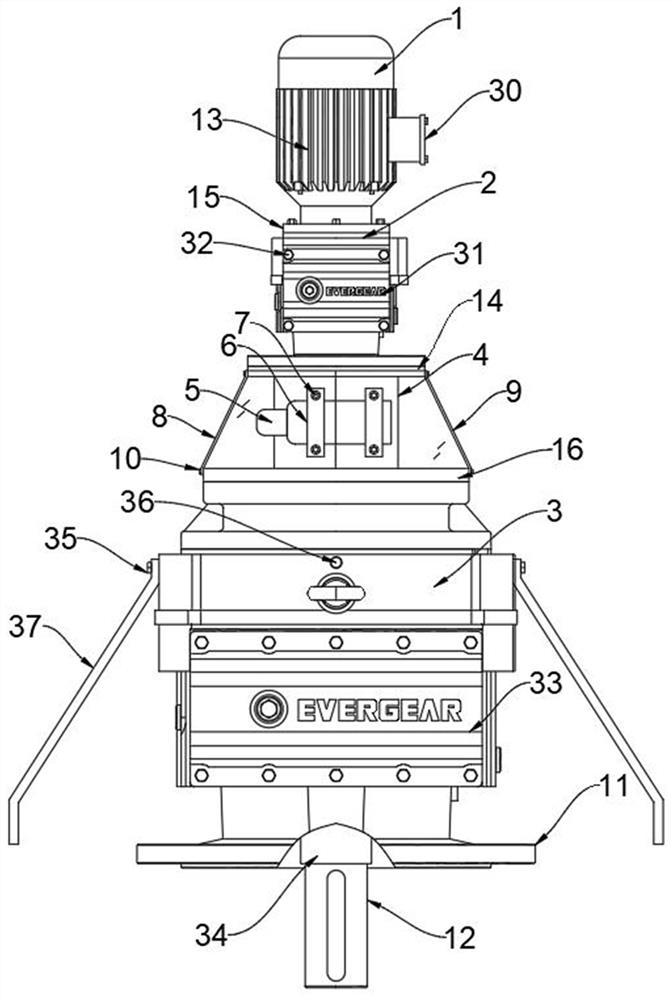

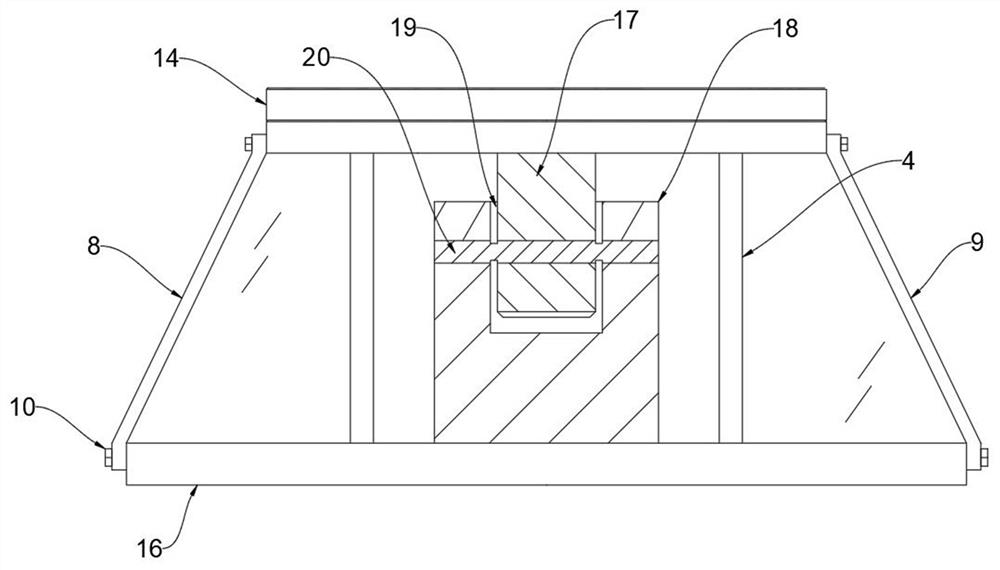

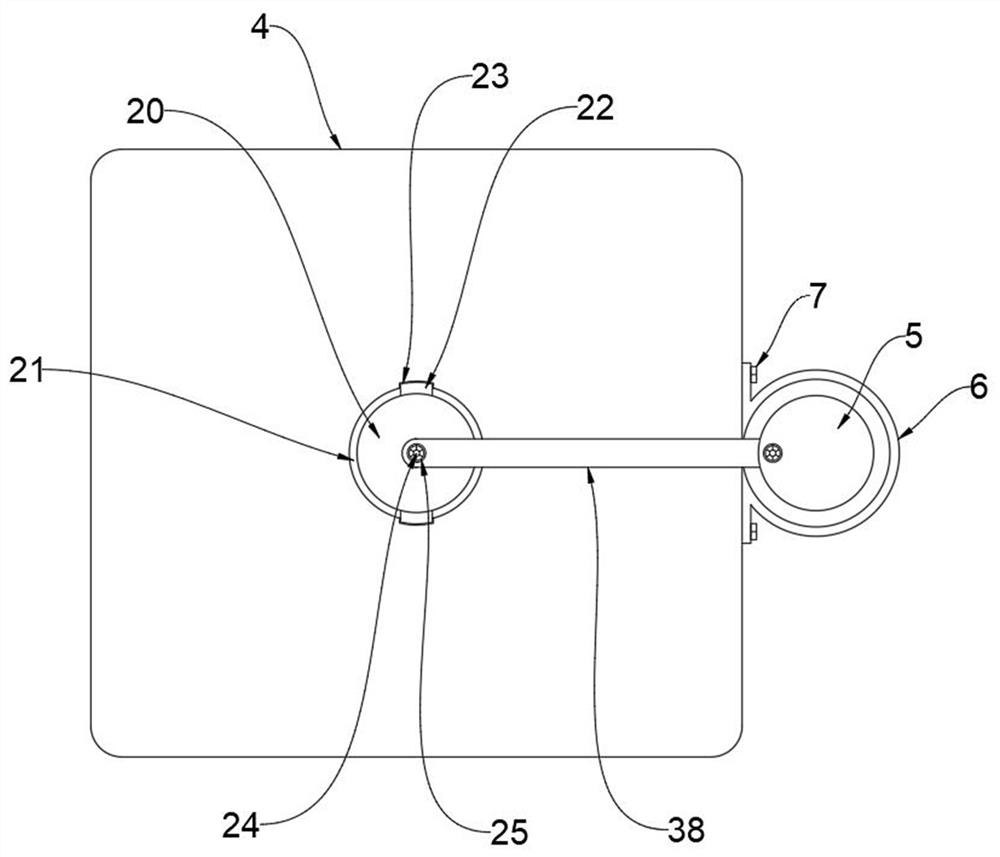

[0035] like Figure 1-5 As shown, a reducer for a mud scraper with a safety pin includes: a motor mechanism 1, and a small reducer mechanism 2 arranged at the lower end of the motor mechanism 1, and the outer wall of the small reducer mechanism 2 is provided with cooling fins 13, and the heat sink 13 is welded and connected with the small reducer mechanism 2, the heat sink 13 is provided with several, and one side of the small reducer mechanism 2 is provided with a control mechanism 30; the large reducer mechanism 3 is arranged on Below the small reducer mechanism 2, a connection sleeve 4 is arranged between the large reducer mechanism 3 and the small reducer mechanism 2; a safety pin 20 is arranged inside the connection sleeve 4, and the safety pin The outside of 20 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com