Fertilizer producing and processing device

A processing device and fertilizer technology, which is applied in the agricultural field, can solve the problems of changing the size of fertilizer particles and single function, and achieve the effect of changing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

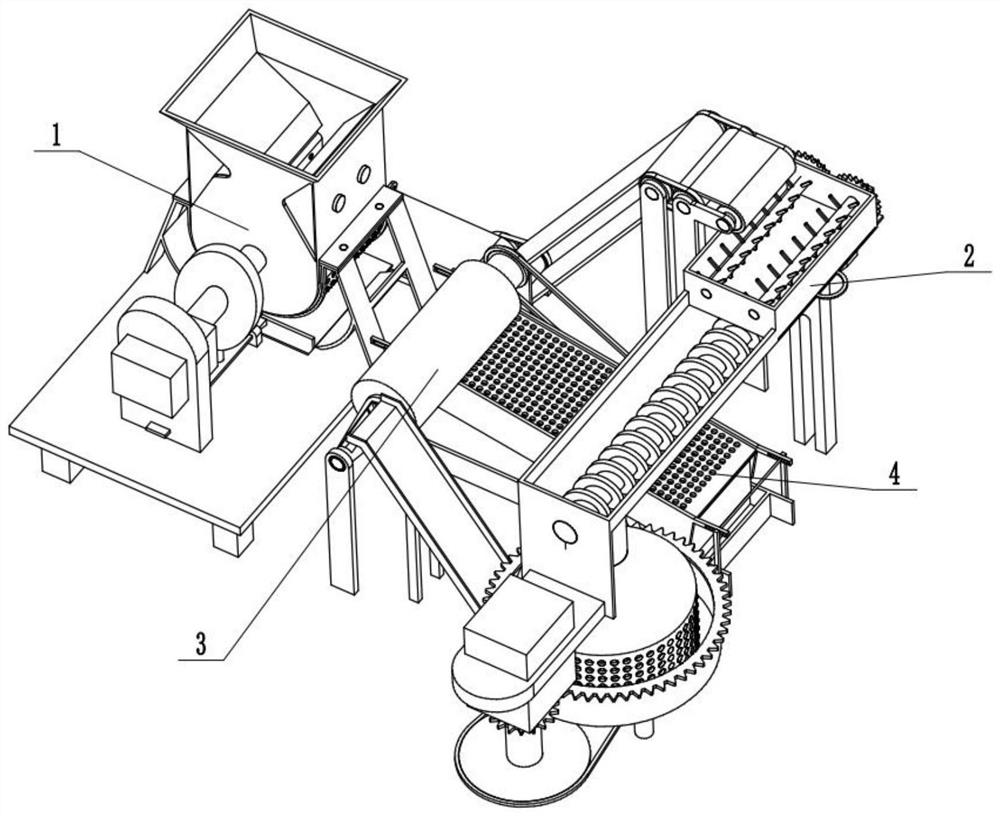

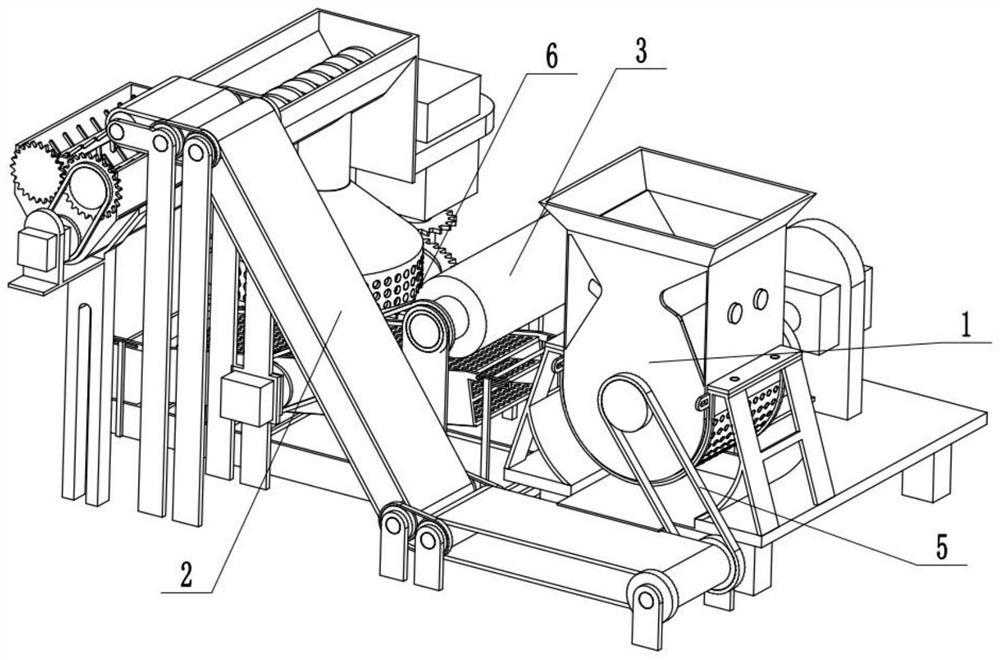

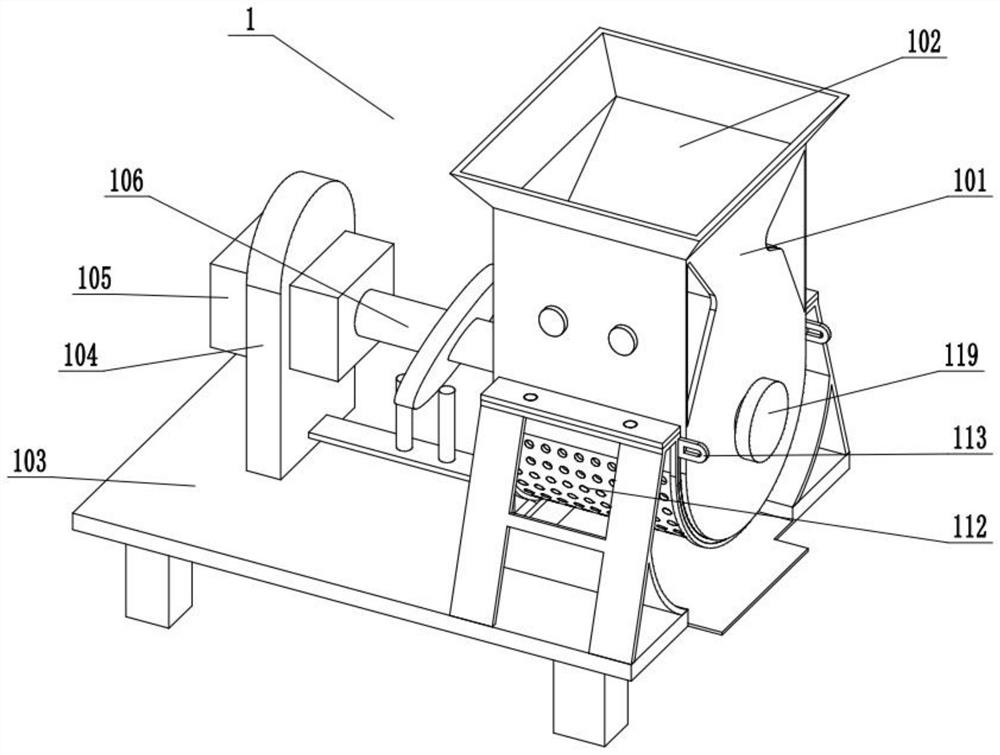

[0033] Put the raw materials into the outer wall 101 of the pulverizer from the feed port 102, start the motor one 105 to drive the long rod 106 to rotate, drive the central shaft 107 to rotate, and then drive the five impellers 108 to rotate, and then crush the large raw materials, and the large raw materials The steel plate 110 and the impeller 108 are repeatedly impacted and crushed, and the steel plate 111 acts as a baffle to prevent the raw materials from flying out. The raw material powder meeting the required size leaks from the screen 112 to the base 103, and the scraper 109 will stick to it. The raw material on the screen 112 is scraped off to prevent the raw material from blocking the screen 112. Pull the two handles 113 to pull out the screen 112 for easy cleaning and replacement of the screen 112. When the long rod 106 rotates, it drives the inclined wheel 114 Rotate to drive the two limit columns 115 to reciprocate back and forth, drive the moving plate 116 to reci...

specific Embodiment approach 2

[0034] Starting motor one 105 drives the pole 106 to rotate, drives the central shaft 107 to rotate, drives the runner one 119 to rotate, drives the belt one 5 to rotate, drives the runner two 201 to rotate, drives the roller one 202 to rotate, drives the conveyor belt one 203 to rotate, and drives the roller Two 204 rotates, drives belt three 205 to rotate, drives roller three 206 to rotate, drives conveyor belt two 207 to rotate, drives roller four 208 to rotate, drives belt four 209 to rotate, drives conveyor belt three 210 to rotate, and then transmits the raw material powder to the mixing tank 211 , add the mixture to the mixing tank 211, start the motor two 212 to drive the five runners 213 to rotate, drive the five belts 214 to rotate, drive the six runners 215 to rotate, drive the gear one 216 to rotate, drive the stirring rod one 218 to rotate, and the gear one 216 The rotation drives the gear two 217 to rotate, drives the stirring rod two 219 to rotate, and then makes...

specific Embodiment approach 3

[0035] Fertilizer particles are uploaded along with the conveying device 301, and fall into the conical empty pipe 303 from the small opening on the conical empty pipe 303, and slide into the functional cylinder 305 to heat the heating rod 306, and start the motor 401 to drive the runner Nine 402 rotates, drives belt two 6 to rotate, drives runner eight 307 to rotate, drives functional cylinder 305 to rotate, and then drives fertilizer granules to roll forward, and then fully dries fertilizer granules, and fertilizer granules fall from the end of functional cylinder 305 to In the screening device 4;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com